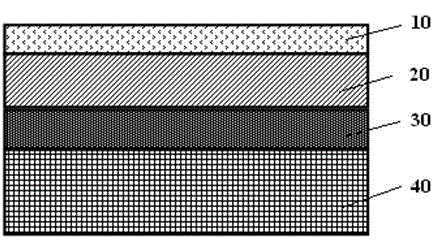

Self-adhesion label for laser etching and preparation method thereof

A technology of laser etching and self-adhesive labels, which is applied in the direction of adhesives, film/sheet adhesives, instruments, etc., can solve the problems of self-adhesive labels that are easily damaged and cannot meet the label quality requirements, and achieve low cost and excellent durability. High temperature resistance and high production flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The black ink formula is as follows: XCD-675 resin (polyurethane resin, Suzhou Asahikawa Chemical) 50 parts by weight, U-4115 black color paste (Shanghai Baishanwei Chemical Technology) 30 parts by weight, SM-5717 crosslinking agent amino resin (Jiangsu Sanmu ) 10 parts by weight, xylene solvent 10 parts by weight. The above-mentioned components were thoroughly mixed to obtain a black ink slurry.

[0063] The white ink formula is as follows: XCD-675 resin (polyurethane resin, Suzhou Asahikawa Chemical) 40 parts by weight, U-4001 white color paste (Shanghai Baishanwei Chemical Technology) 40 parts by weight, SM-5717 crosslinking agent amino resin (Jiangsu Sanmu ) 8 parts by weight, butanone solvent 12 parts by weight. The above-mentioned components are fully mixed to obtain a white ink slurry.

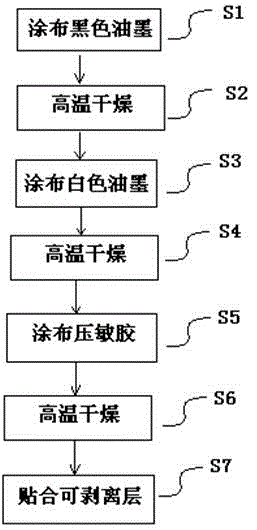

[0064] Preparation of self-adhesive labels: eg figure 2 As shown, in step S1, the above-mentioned black ink slurry is uniformly coated on the release film; in step S2, t...

Embodiment 2

[0067] The black ink formula is as follows: XCD-675 resin (polyurethane resin, Suzhou Asahikawa Chemical) 40 parts by weight, U-4115 black color paste (Shanghai Baishanwei Chemical Technology) 30 parts by weight, SM-5717 crosslinking agent amino resin (Jiangsu Sanmu ) 20 parts by weight, xylene solvent 10 parts by weight. The above-mentioned components were thoroughly mixed to obtain a black ink slurry.

[0068] The white ink formula is as follows: XCD-675 resin (polyurethane resin, Suzhou Xuchuan Chemical) 60 parts by weight, U-4001 white color paste (Shanghai Baishanwei Chemical Technology) 20 parts by weight, SM-5717 crosslinking agent amino resin (Jiangsu Sanmu ) 5 parts by weight, 15 parts by weight of butanone solvent. The above-mentioned components are fully mixed to obtain a white ink slurry.

[0069] The preparation method and detection method of the self-adhesive label are the same as in Example 1, and the performance test results are shown in Table 1-2. The ...

Embodiment 3

[0071] The black ink formula is as follows: XCD-675 resin (polyurethane resin, Suzhou Xuchuan Chemical) 57 parts by weight, U-4115 black color paste (Shanghai Baishanwei Chemical Technology) 15 parts by weight, SM-5717 crosslinking agent amino resin (Jiangsu Sanmu ) 8 parts by weight, xylene solvent 20 parts by weight. The above-mentioned components were thoroughly mixed to obtain a black ink slurry.

[0072] The white ink formula is as follows: XCD-675 resin (polyurethane resin, Suzhou Xuchuan Chemical) 50 parts by weight, U-4001 white color paste (Shanghai Baishanwei Chemical Technology) 23 parts by weight, SM-5717 crosslinking agent amino resin (Jiangsu Sanmu ) 10 parts by weight, and 17 parts by weight of cyclohexanone solvent. The above-mentioned components are fully mixed to obtain a white ink slurry.

[0073] The preparation method and detection method of the self-adhesive label are the same as in Example 1, and the performance test results are shown in Table 1-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com