FeS flaky array film and preparation method thereof

An array and flake technology, which is applied in the field of FeS flake array thin film and its preparation, can solve the problems of powdering and peeling of electrode materials, achieve the effects of improving electrical conductivity, high structural stability, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

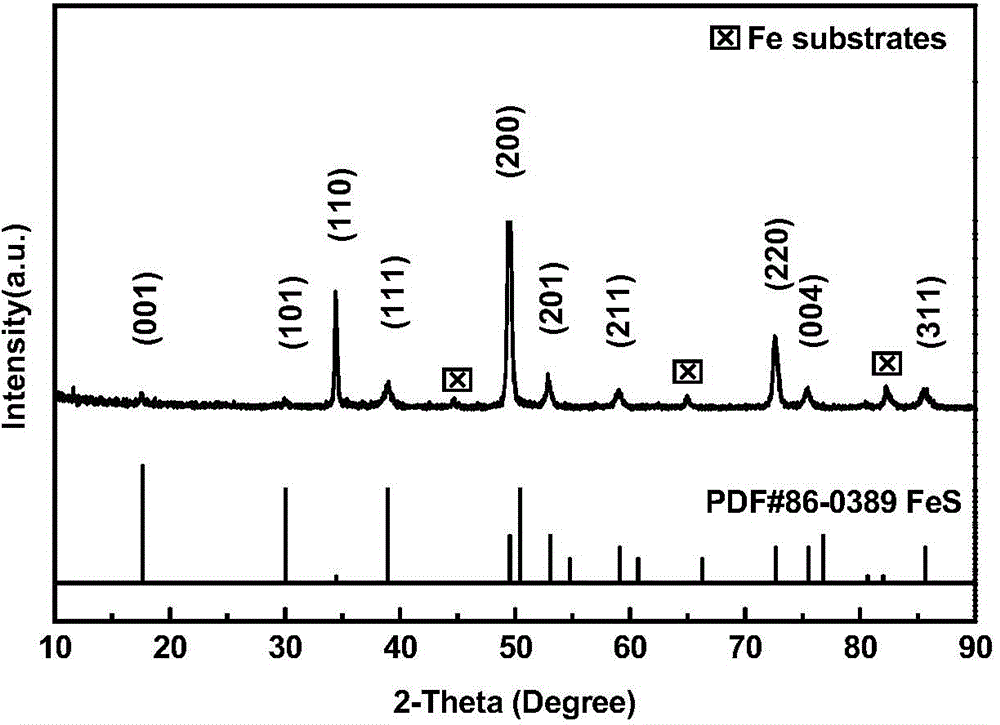

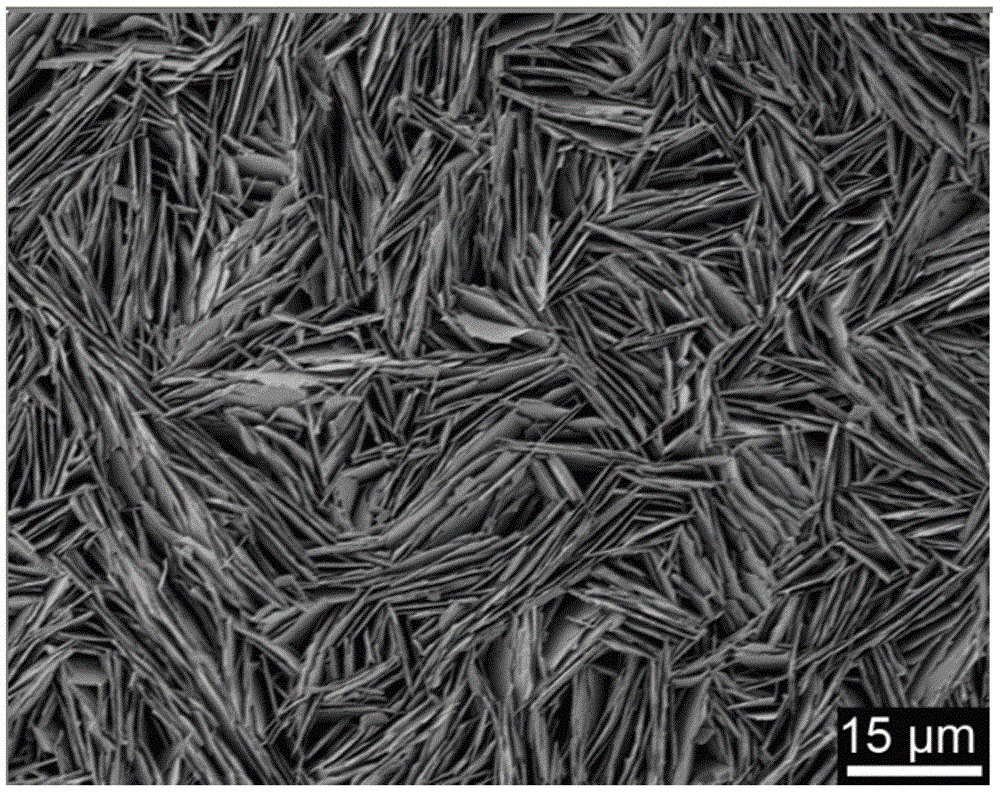

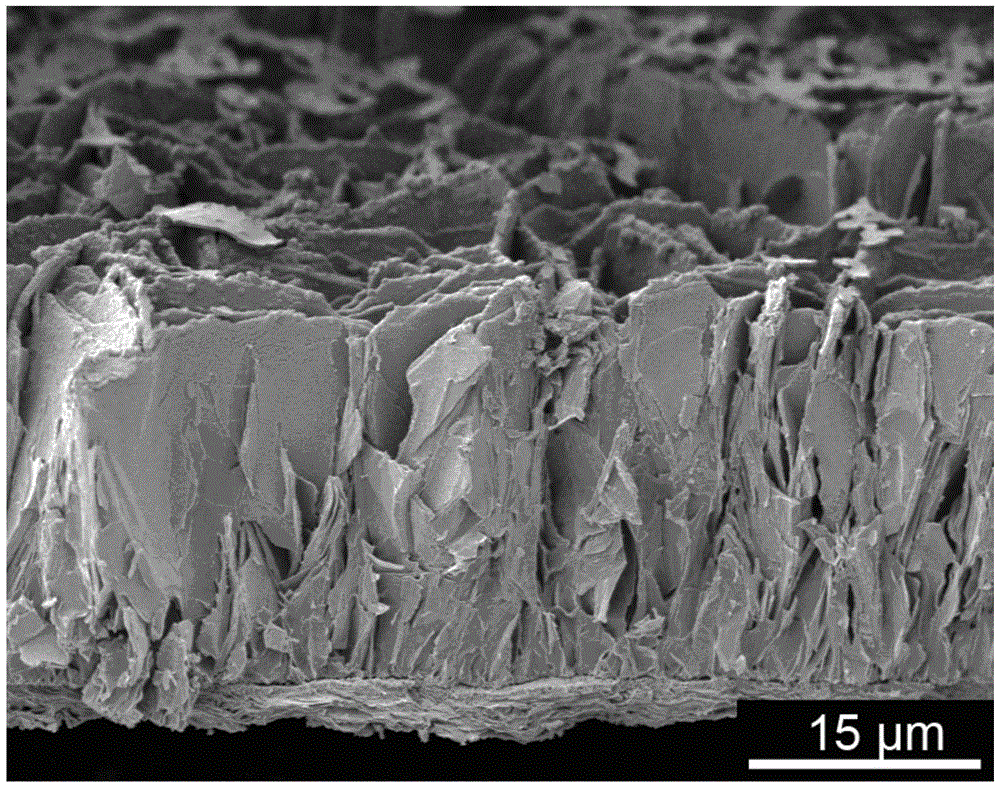

[0020] With reference to accompanying drawing, further illustrate the present invention:

[0021] The preparation method of FeS flake array film comprises the following steps:

[0022] 1) Use iron foil as the base, the purity of the iron foil is >99%, and the thickness of the iron foil is 0.05mm. The iron foil base is ultrasonically cleaned in acetone, absolute ethanol, and deionized water for 20 minutes respectively, and the cleaned base dry and ready for use;

[0023] 2), 2mmol sodium sulfide nonahydrate (Na 2 S·9H 2 O) and 2 mmol of sulfur powder (S) were dissolved in 30 mL of deionized water, and magnetically stirred at 70 ° C until the sulfur powder was completely dissolved. After forming a uniform and transparent light yellow solution, 0.5 mmol of ferric chloride hexahydrate (FeCl 3 ·6H 2 O) and 30mL ethylenediamine (NH 2 CH 2 CH 2 NH 2 ) continue magnetic stirring to form a black uniform solution; the addition of ethylenediamine can form a chelate with metal ion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com