Flexible lithium secondary battery and preparation method thereof

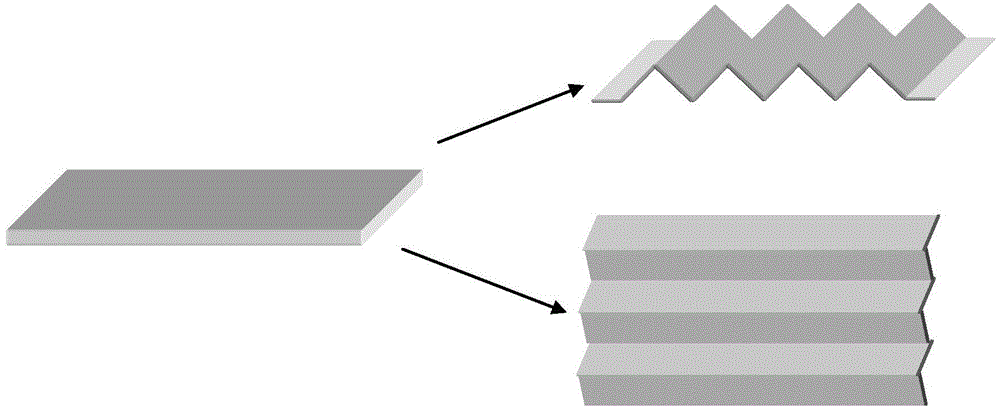

A technology for lithium secondary batteries and flexible batteries, which is applied in the manufacture of secondary batteries, lithium storage batteries, and electrolyte storage batteries, can solve the problems that the thickness cannot meet the requirements of flexible electronic products, the peeling of rigid active material particles, and the lack of flexibility, so as to reduce the size of the battery. Thickness, high battery energy density and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] In a second aspect, an embodiment of the present invention provides a method for preparing a flexible lithium secondary battery, comprising the following steps:

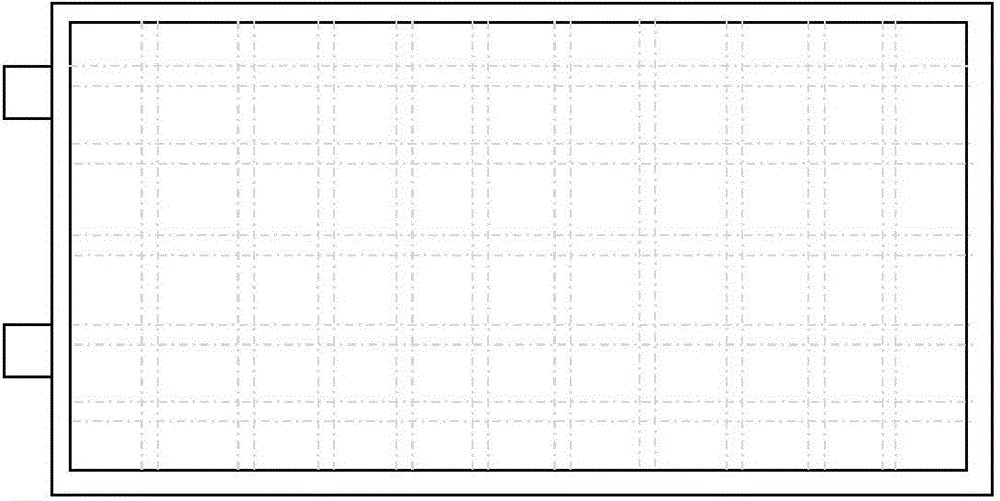

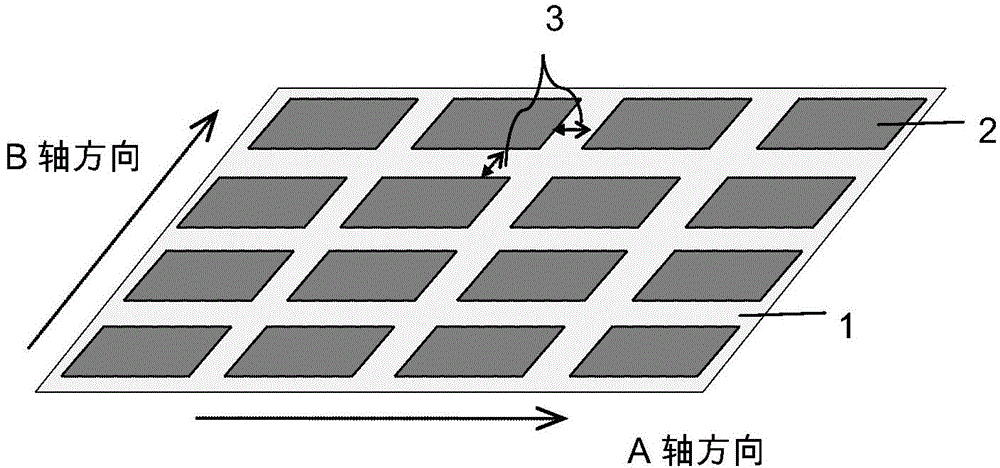

[0049] Coating the positive electrode slurry on the positive electrode current collector in an array structure, baking and pressing to obtain a positive electrode sheet, the positive electrode sheet includes a plurality of positive electrode active material layers arranged in an array on the positive electrode current collector;

[0050] Coating the negative electrode slurry on the negative electrode current collector in an array structure, and obtaining a negative electrode sheet after baking and pressing, the negative electrode sheet includes a plurality of negative electrode active material layers arranged in an array on the negative electrode current collector; The negative electrode sheet has an array gap corresponding to the positive electrode sheet; the width of the array gap is 5 mm to 50 mm;

[0051] ...

Embodiment 1

[0072] A method for preparing a flexible lithium secondary battery, comprising the following steps:

[0073] (1) Mix lithium cobalt oxide, binder PVDF and conductive carbon black at a weight ratio of 96:2:2, add a certain amount of organic solvent nitrogen methyl pyrrolidone, and use a planetary high-speed disperser to disperse to obtain positive electrode slurry. The obtained positive electrode slurry is sprayed on the aluminum foil current collector in an array structure to form a plurality of positive electrode active material layers arranged in an array on the aluminum foil current collector, and then baked and pressed to obtain the positive electrode sheet;

[0074] (2) Mix artificial graphite, binder PVDF, and conductive carbon black at a weight ratio of 95:3:2, add a certain amount of organic solvent nitrogen methyl pyrrolidone, and use a planetary high-speed disperser to disperse to obtain negative electrode slurry. The negative electrode slurry is sprayed on the coppe...

Embodiment 2

[0081] A method for preparing a flexible lithium secondary battery, comprising the following steps:

[0082] (1) Mix lithium iron phosphate, binder PVDF and conductive carbon black at a weight ratio of 96:2:2, add a certain amount of organic solvent nitrogen methyl pyrrolidone, and use a planetary high-speed disperser to disperse to obtain positive electrode slurry. The obtained positive electrode slurry is sprayed on the aluminum foil current collector in an array structure to form a plurality of positive electrode active material layers arranged in an array on the aluminum foil current collector, and then baked and pressed to obtain the positive electrode sheet;

[0083] (2) Mix artificial graphite, binder PVDF, and conductive carbon black at a weight ratio of 95:3:2, add a certain amount of organic solvent nitrogen methyl pyrrolidone, and use a planetary high-speed disperser to disperse to obtain negative electrode slurry. The negative electrode slurry is sprayed on the cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com