Sponge substrate carrier gel polymer electrolyte and preparation method thereof

A gel polymer, matrix carrier technology, used in organic electrolytes, non-aqueous electrolytes, circuits, etc., can solve problems such as poor mechanical properties, poor dimensional stability, and inability to form large-scale factory films. Inexpensive, solve the effect of poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

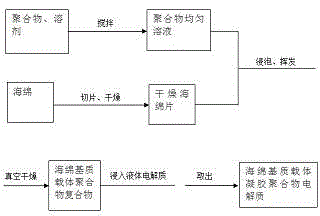

Method used

Image

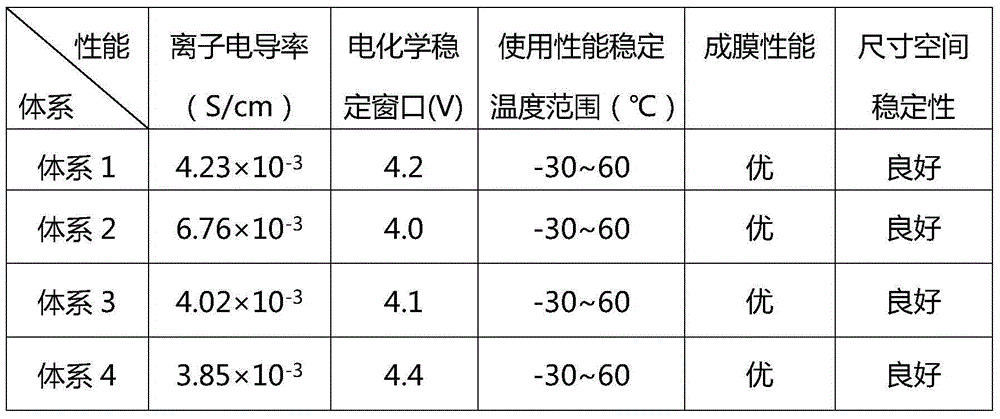

Examples

Embodiment 1

[0020] (1) Polymethyl methacrylate is dissolved in acetone at room temperature, and stirred to obtain a uniform solution;

[0021] (2) Soak a dry sponge with a thickness of 120 μm in the obtained solution. After it absorbs the solution in a large amount, take it out with tweezers, and evaporate the solvent from the sponge to obtain a sponge matrix carrier polymethyl methacrylate compound , and then placed in a vacuum oven at 50°C to remove trace solvents;

[0022] (3) Immerse the obtained dry sponge matrix carrier polymethyl methacrylate compound in the glove box at a concentration of 1mol L -1 In the lithium perchlorate propylene carbonate liquid electrolyte, when it absorbs the maximum amount of liquid electrolyte and the polymer forms a gel, a sponge matrix carrier gel polymethyl methacrylate electrolyte is prepared, which is named system 1.

Embodiment 2

[0024] (1) Polyacrylonitrile is dissolved in acetone at room temperature, and stirred to obtain a uniform solution;

[0025] (2) Soak a dry sponge with a thickness of 250 μm in the obtained solution. After it absorbs the solution to the maximum, it is taken out with tweezers, and the solvent is volatilized from the sponge to obtain a sponge matrix carrier polyacrylonitrile composite, and then Place in a vacuum oven at 60°C to remove trace solvents;

[0026] (3) Immerse the obtained dry sponge matrix carrier polyacrylonitrile compound in the glove box at a concentration of 1mol L -1 In the lithium perchlorate dimethyl carbonate liquid electrolyte, when it absorbs the maximum amount of liquid electrolyte and the polymer forms a gel, a sponge matrix carrier gel polyacrylonitrile electrolyte is prepared, which is named system 2.

Embodiment 3

[0028] (1) Poly(methyl methacrylate-vinyl acetate) copolymer is dissolved in tetrahydrofuran at room temperature, and stirred to obtain a uniform solution;

[0029] (2) Soak a dry sponge with a thickness of 350 μm in the obtained solution. After it absorbs the solution in a large amount, it is taken out with tweezers, and the solvent is volatilized from the sponge to obtain a sponge matrix carrier poly(methyl methacrylate- Vinyl acetate) complex, and then placed in a vacuum oven at 70 ° C to remove trace solvents;

[0030] (3) Immerse the obtained dry sponge matrix carrier poly(methyl methacrylate-vinyl acetate) composite in the glove box at a concentration of 1mol L -1 In the lithium hexafluorophosphate dimethyl carbonate liquid electrolyte, when it absorbs the maximum amount of liquid electrolyte and the polymer forms a gel, a sponge matrix carrier gel poly(methyl methacrylate-vinyl acetate) electrolyte is prepared, which is named system 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com