Soft ice cream milk sauce and preparation method thereof

A technology of soft ice cream mix and cream, applied in frozen desserts, food science, applications, etc., can solve the problems of unsatisfactory flavor and taste, short shelf life, etc., and achieve good firmness, stable shelf life, and good fat feeling and creamy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

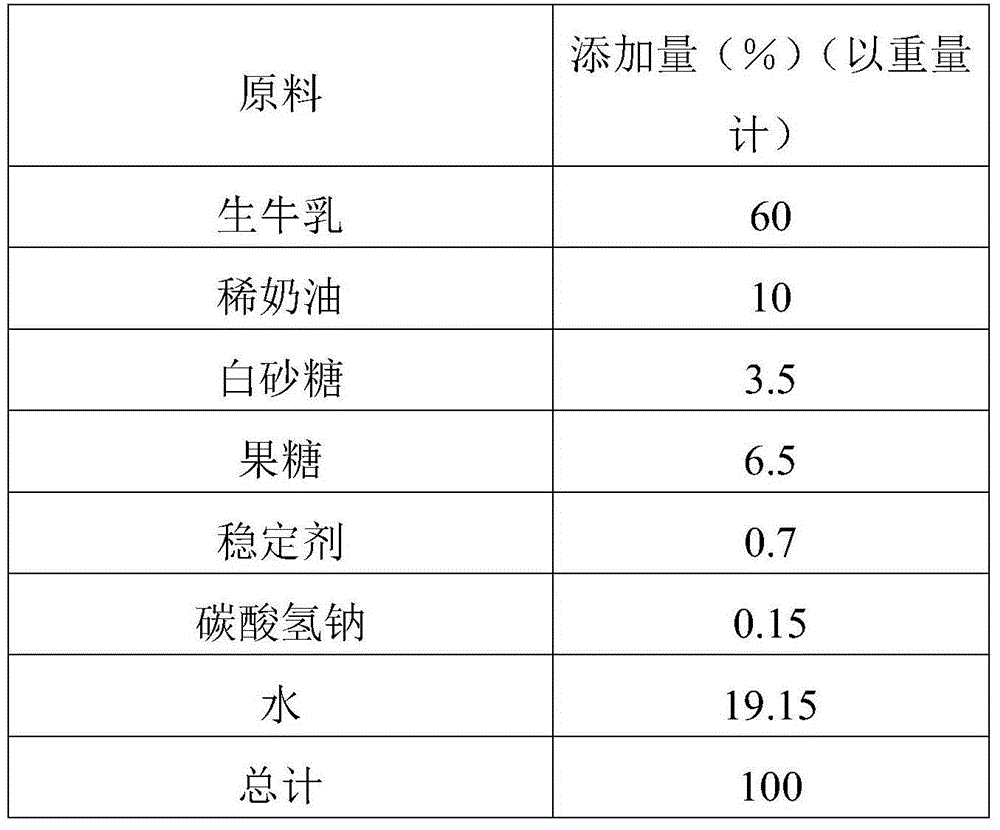

[0040] 1. Raw material formula (see Table 1):

[0041] The raw material formula of table 1 embodiment 1

[0042]

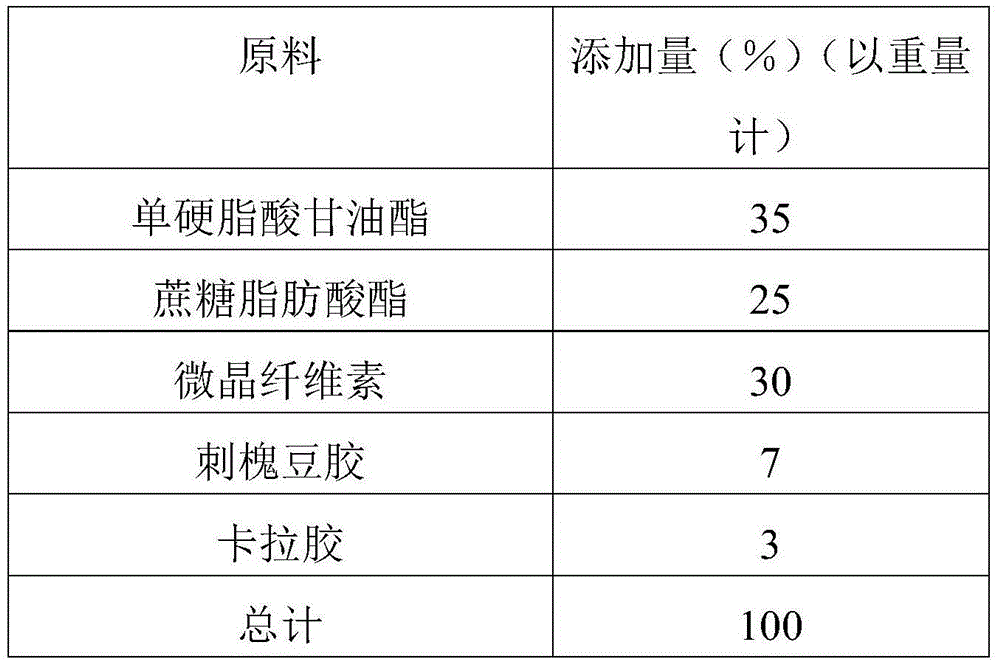

[0043] Wherein, stabilizer comprises (see table 2):

[0044] Table 2 Stabilizer formulation

[0045]

[0046] 2. Preparation method:

[0047] (1) Heat raw milk to 65°C, add cream, white sugar, fructose, stabilizer, sodium bicarbonate and water through a water powder mixer, stir evenly for 30 minutes, and mix well;

[0048] (2) The fat content in the mixed solution is 5.86%, the protein content is 1.74%, and the pH value is 6.7, and the uniform mixed solution is poured into a homogenizer, the homogenization pressure is 15MPa, and the homogenization temperature is 65°C;

[0049] (3) Carry out tubular ultra-high temperature sterilization, the sterilization temperature is 137°C, and the sterilization time is 4s;

[0050] (4) The milk after ultra-high temperature treatment is directly poured into the aseptic homogenizer, the homogenization pressure is 15MPa, ...

Embodiment 2

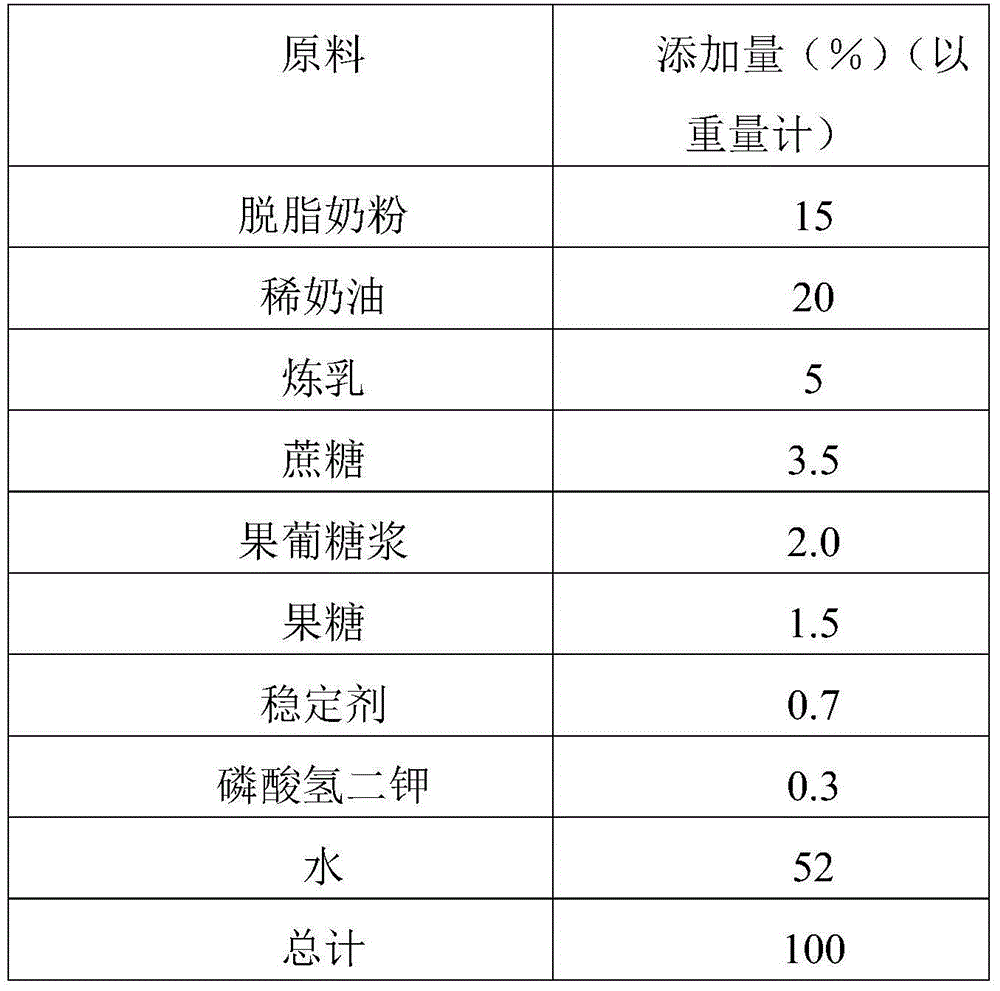

[0053] 1. Raw material formula (see Table 3):

[0054] The raw material formula of table 3 embodiment 2

[0055]

[0056] Wherein, stabilizer comprises (see table 4):

[0057] Table 4 Stabilizer formulation

[0058]

[0059]

[0060] 2. Preparation method:

[0061] (1) Stir skimmed milk powder and part of water at 45°C for 30 minutes, keep warm and hydrate for 8 hours, then raise the temperature to 70°C, add cream, condensed milk, sucrose, fructose syrup, fructose, stabilizer, dipotassium hydrogen phosphate and remaining Part of the water, mixed and stirred for 15min.

[0062] (2) The fat content in the mixed solution is 8.0%, the protein content is 4.8%, and the pH value is 7.0. The homogeneous mixed solution is poured into a homogenizer with a homogenizing pressure of 20 MPa and a homogenizing temperature of 70° C.;

[0063] (3) Carry out plate-type UHT sterilization, the sterilization temperature is 137°C, and the sterilization time is 4s;

[0064] (4) The UHT...

Embodiment 3

[0067] 1. Raw material formula (see Table 5):

[0068] The raw material formula of table 5 embodiment 3

[0069]

[0070]

[0071] Wherein, stabilizer comprises (see table 6):

[0072] Table 6 Stabilizer formulation

[0073]

[0074] 2. Preparation method:

[0075] (1) Heat raw milk to 75°C, add cream, condensed milk, fructose syrup, sucralose, stabilizer, sodium citrate, milk essence, vanilla essence and water through a water powder mixer, stir evenly for 30 minutes, and mix well ;

[0076] (2) The fat content in the mixed solution is 7.05%, the protein content is 1.90%, and the pH value is 6.65, and the uniformly mixed mixed solution is poured into a homogenizer, the homogenization pressure is 15MPa, and the homogenization temperature is 70°C;

[0077] (3) Carry out plate-type UHT sterilization, the sterilization temperature is 145°C, and the sterilization time is 3s;

[0078] (4) The UHT-treated milk is directly poured into the aseptic homogenizer, the homogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com