Hollow fiber ultrafiltration membrane module casting device, and casting method thereof

A technology of ultrafiltration membrane and membrane module, which is applied in the field of membrane separation, can solve problems such as unsealable, low production efficiency and sealing failure rate, and membrane module can not meet the requirements, so as to achieve good sealing performance, avoid colloid cracking, and yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

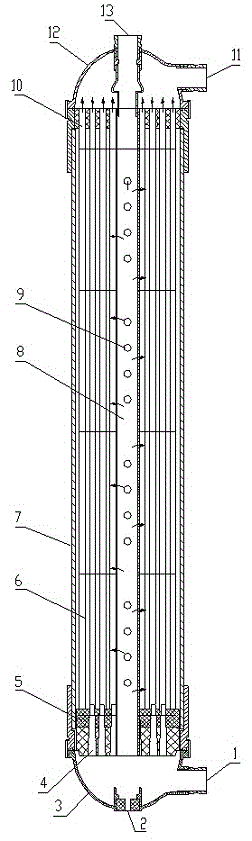

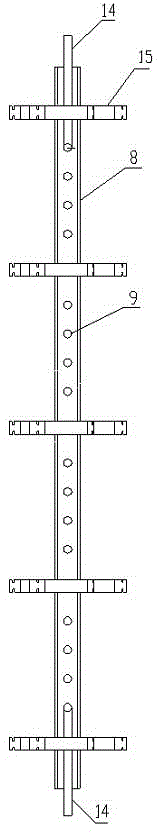

[0047] see Figure 5 to Figure 7 , a casting device for a hollow fiber ultrafiltration membrane module, comprising a membrane module and a membrane housing 7, the membrane module is placed in the membrane housing 7, and the two ends of the membrane housing 7 are respectively connected to a liquid outlet mold 20 and a liquid inlet mold 19, and the membrane Both ends of the shell 7 are provided with an end body 25, the end body 25 is provided with an annular groove 26, a U-shaped clip 27 is connected between the liquid outlet mold 20 and the end body 25, and the liquid inlet mold 19 and the end body 25 are connected to each other. There is also a U-shaped clip 27 connected between them, one end of the U-shaped clip 27 is clipped in the annular groove 26 on the end body 25, and the other end is clipped on the end surface of the liquid outlet mold 20 or the liquid inlet mold 19; the liquid outlet Both the end mold 20 and the liquid inlet mold 19 are provided with a primary rubber ...

Embodiment 2

[0052] Utilize the hollow fiber ultrafiltration membrane module casting device casting method of embodiment one to cast the method for hollow fiber ultrafiltration membrane module, specifically comprise the following steps:

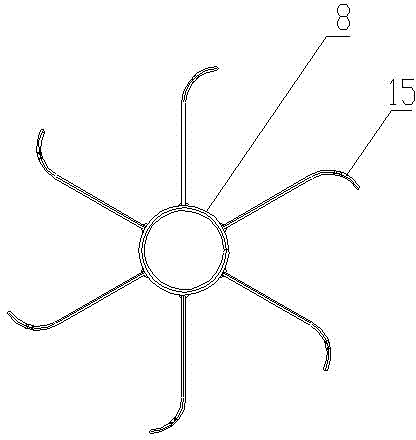

[0053] (1) The hollow fiber membranes are made into tows, and then the tows are placed on a cage with a central tube and bound and fixed to obtain a membrane module;

[0054] (2) Place the membrane shell flat, fill the membrane module in the membrane shell, the length of the tow is greater than the length of the membrane shell, according to the cylindrical groove of the liquid outlet mold and the conical groove of the liquid inlet mold Cut the membrane wires at both ends to ensure that when the liquid outlet mold and the liquid inlet mold are closed, one end of the membrane wire just touches the bottom of the cylindrical groove of the liquid outlet mold, and the other end just touches the liquid inlet mold. On the conical surface of the conical groove, th...

Embodiment 3

[0066] Utilize the hollow fiber ultrafiltration membrane module casting device casting method of embodiment one to cast the method for hollow fiber ultrafiltration membrane module, specifically comprise the following steps:

[0067] (1) The hollow fiber membranes are made into tows, and then the tows are placed on a cage with a central tube and bound and fixed to obtain a membrane module;

[0068] (2) Place the membrane shell flat, fill the membrane module in the membrane shell, the length of the tow is greater than the length of the membrane shell, according to the cylindrical groove of the liquid outlet mold and the conical groove of the liquid inlet mold Cut the membrane wires at both ends to ensure that when the liquid outlet mold and the liquid inlet mold are closed, one end of the membrane wire just touches the bottom of the cylindrical groove of the liquid outlet mold, and the other end just touches the liquid inlet mold. On the conical surface of the conical groove, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com