A kind of mixed enhanced bonded gypsum and its preparation method

A bonding gypsum, enhanced technology, applied in the field of comprehensive utilization of industrial solid waste and chemical building materials, can solve the problems of poor bonding force and water retention, short setting time, waste of materials, etc., and achieve good bonding strength The effect of compressive strength, simple configuration process, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

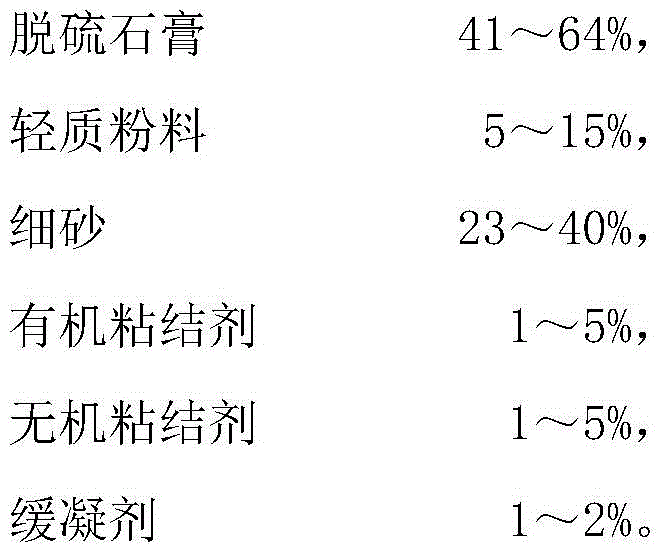

Method used

Image

Examples

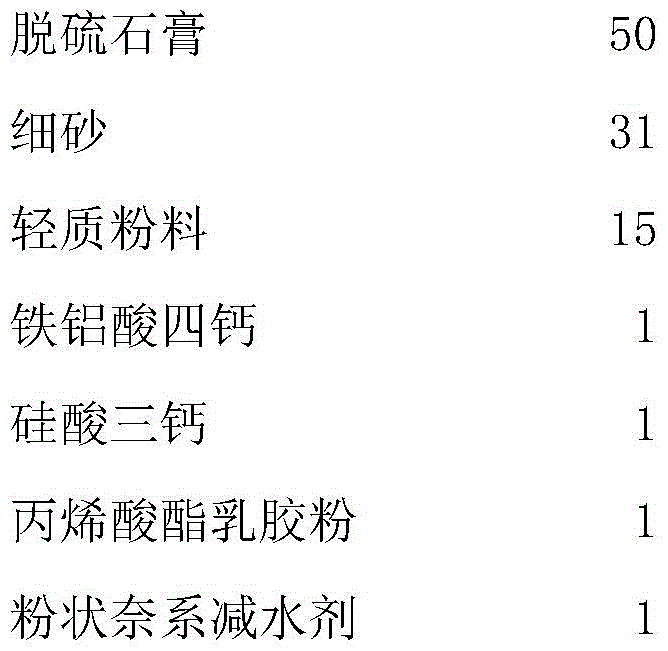

Embodiment 1

[0021] In this embodiment, the preparation of 100 kg of mixed reinforced cemented gypsum is taken as an example, and its preparation method is as follows.

[0022] Weigh the ingredients according to the prescribed ratio, and the dosage (kg) of each raw material is as follows:

[0023]

[0024] Desulfurization gypsum is the waste residue produced after desulfurization of flue gas in power plants, and hemihydrate gypsum (CaSO 4 1 / 2H 2 O), ground to 0.045mm, square hole sieve residual ≤ 3.6%.

[0025] The fine sand is yellow sand with quartz sandstone as raw material to produce high-grade lightweight aggregate concrete, with a mesh number of 60-80 mesh.

[0026] The light powder is silica fume, more than 80% of which have a fineness of ≤1μm, the particle size is 0.1-0.3μm, and the specific surface area is 25m 2 / g.

[0027] The powdery Nai series superplasticizer is FDN210 from Shanghai Huiyu Industrial Co., Ltd.

[0028] Put the above-mentioned various raw materials into...

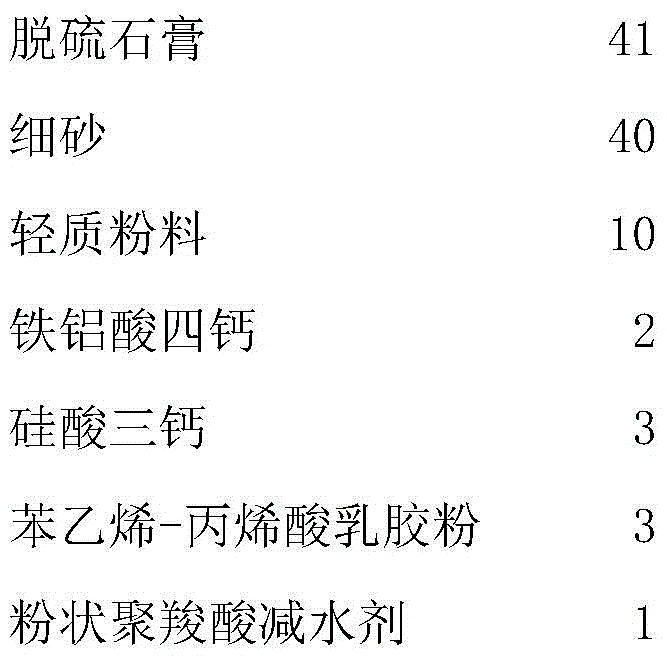

Embodiment 2

[0031] In this embodiment, the preparation of 100 kg of mixed reinforced cemented gypsum is taken as an example, and its preparation method is as follows.

[0032] Weigh the ingredients according to the prescribed ratio, and the dosage (kg) of each raw material is as follows:

[0033]

[0034] Desulfurization gypsum is the waste residue produced after desulfurization of flue gas in power plants, and hemihydrate gypsum (CaSO 4 1 / 2H 2 O), ground to 0.035mm, square hole sieve residual ≤ 6.8%.

[0035] The fine sand is yellow sand with quartz sandstone as raw material to produce high-grade lightweight aggregate concrete, with a mesh number of 80-100 mesh.

[0036] The light powder is silica fume, more than 80% of which have a fineness of ≤1μm, the particle size is 0.1-0.2μm, and the specific surface area is 28m 2 / g.

[0037] The powdery polycarboxylate superplasticizer is selected from Fuke Technology (Canada) Niyon-790.

[0038] Put the above-mentioned various raw mate...

Embodiment 3

[0041] In this embodiment, the preparation of 100 kg of mixed reinforced cemented gypsum is taken as an example, and its preparation method is as follows.

[0042] Weigh the ingredients according to the prescribed ratio, and the dosage (kg) of each raw material is as follows:

[0043]

[0044] Desulfurization gypsum is the waste residue produced after desulfurization of flue gas in power plants, and hemihydrate gypsum (CaSO 4 1 / 2H 2 O), ground to 0.055mm, square hole sieve residual ≤ 10%.

[0045] The fine sand is yellow sand with quartz sandstone as raw material to produce high-grade lightweight aggregate concrete, with a mesh number of 100-120 mesh.

[0046] The light powder is silica fume, more than 80% of which have a fineness of ≤1μm, the particle size is 0.2-0.3μm, and the specific surface area is 20m 2 / g.

[0047] The powdery Nai series superplasticizer is FDN210 from Shanghai Huiyu Industrial Co., Ltd.

[0048] Put the above-mentioned various raw materials int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com