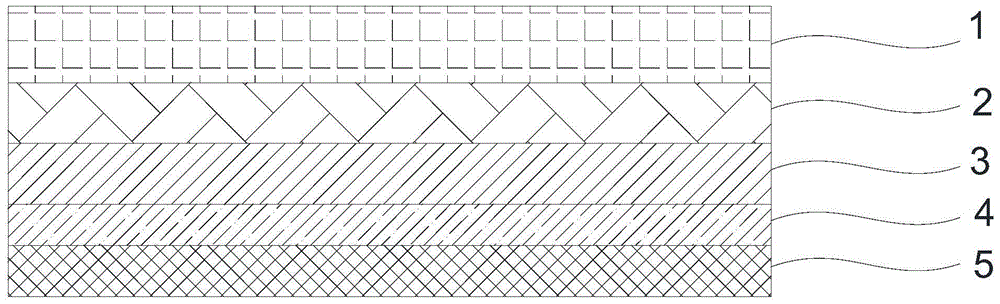

Self-absorbing self-exhausting silica gel, preparation method and tempered glass protective film for its application

A tempered glass and self-exhausting technology, which is applied in chemical instruments and methods, glass/slag layered products, rubber layered products, etc., can solve the problem of high precision of machines, poor adsorption and exhaust performance of silica gel surface, guide rollers, etc. There can be no problems such as dust and bending, so as to achieve the effect of easy purchase, touch sensitivity and increased tolerance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

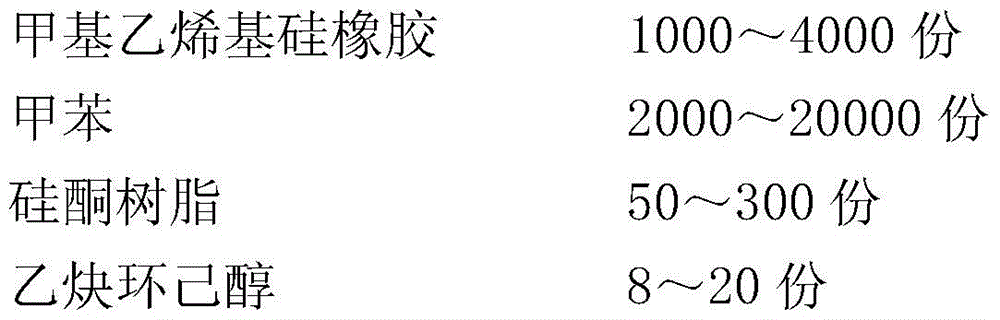

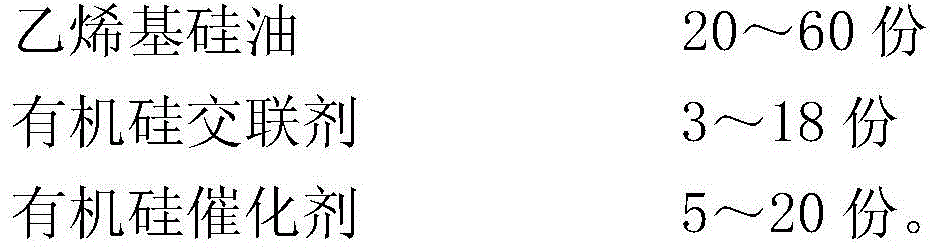

[0037] At room temperature, place 2,000-20,000 parts of toluene in a non-polluting glue container and disperse and stir at a speed of 300-500r / min. Slowly add 1,000-4,000 parts of methyl vinyl silicone rubber during the stirring process, and then adjust the stirring Speed up to 900-1600r / min, stir for 2-8 hours to obtain liquid phase A for use; add 50-300 parts of silicone resin to liquid phase A and stir at 900-1600r / min for 8-10 minutes to obtain liquid phase B; Put 20-60 parts of vinyl silicone oil in another non-polluting glue preparation container and disperse and stir at a speed of 500-600r / min. During the stirring process, add 8-20 parts of acetylene cyclohexanol and mix again Stir for 15-25 minutes, and the liquid is completely mixed to obtain liquid phase C; add liquid phase C to liquid phase B, and stir at a speed of 900-1500r / min for 1-2 hours to obtain liquid phase D; then mix 3 to 18 parts The organosilicon crosslinking agent was added to liquid phase D and cont...

Embodiment 2

[0040]At room temperature, place 8,000-12,000 parts of toluene in a non-polluting glue container and disperse and stir at a speed of 300r / min. Slowly add 2,000-3,000 parts of methyl vinyl silicone rubber during the stirring process, and then adjust the stirring speed to 1200r / min, stirred for 5 hours to obtain liquid phase A for use; add 100-200 parts of silicone resin to liquid phase A and stir at 1200r / min for 10 minutes to obtain liquid phase B; 40-50 parts of vinyl Place the silicone oil in another non-polluting glue preparation container and disperse and stir at a speed of 550r / min. During the stirring process, add 10-15 parts of acetylene cyclohexanol, and then mix and stir for 20 minutes. After the liquid is completely mixed, a liquid phase C is obtained. ; Add liquid phase C to liquid phase B and stir at a speed of 1200r / min for 1.5 hours to obtain liquid phase D; Stir for 10 minutes to obtain liquid phase E; finally add 10 to 15 parts of organosilicon catalyst into li...

Embodiment 3

[0043] At room temperature, place 10,000 parts of toluene in a non-polluting glue container and disperse and stir at a speed of 350r / min. During the stirring process, slowly add 2500 parts of methyl vinyl silicone rubber, and then adjust the stirring speed to 1200r / min. After stirring for 5 hours, liquid phase A was obtained for use; 150 parts of silicone resin was added to liquid phase A and stirred at 1200r / min for 10 minutes to obtain liquid phase B; 45 parts of vinyl silicone oil was placed in another non-polluting Disperse and stir at a speed of 550r / min in the glue preparation container, add 12 parts of acetylene cyclohexanol during the stirring process, and mix and stir for 20 minutes, and obtain liquid phase C after the liquid is completely mixed; add liquid phase C to liquid phase B , stirred at a speed of 1200r / min for 1.5 hours to obtain liquid phase D; then added 13 parts of silicone crosslinking agent into liquid phase D and continued to stir at a speed of 1200r / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com