On-line analyzer and analysis method of mercury in flue gas based on wet enrichment

An analyzer and enrichment technology, applied in the direction of using wave/particle radiation for material analysis, analysis of materials, instruments, etc., can solve the problems of inability to verify the preservation of samples, high cost, safety hazards, etc., to achieve a wide range of applications and reduce energy. Consumption and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

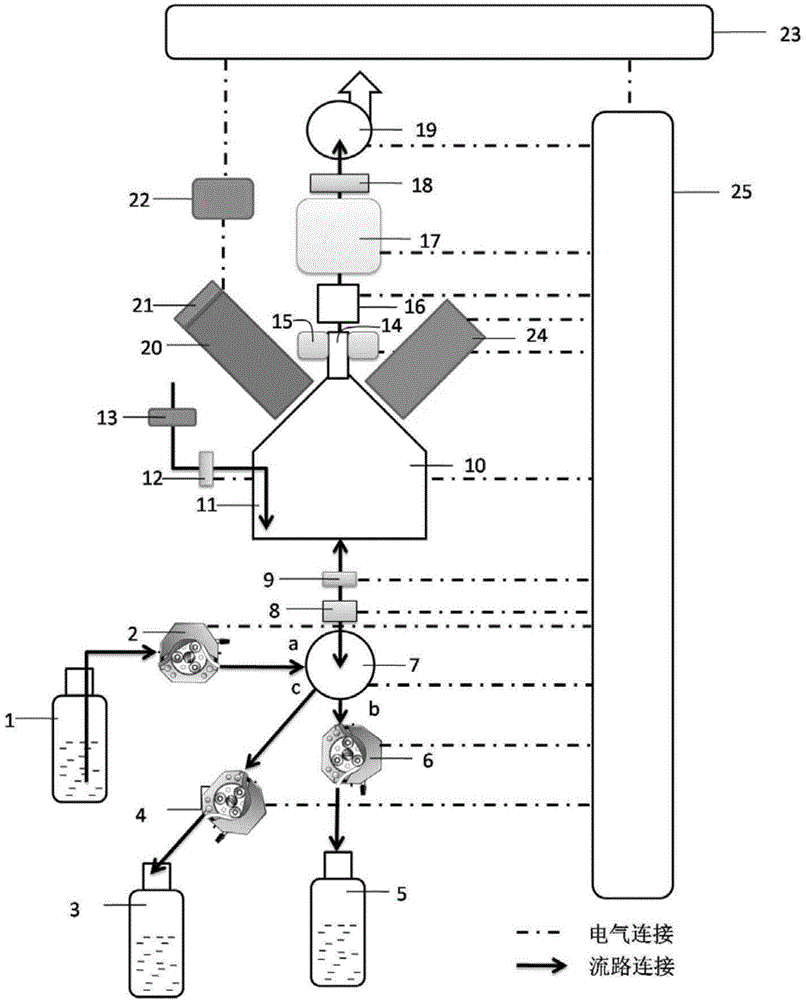

[0049] The flue gas mercury online analyzer based on wet method enrichment of the present invention includes an enrichment system, a detection system and a control system.

[0050] The enrichment system is used to enrich the gaseous mercury in the solution, increase the concentration of the determination solution, and improve the detection limit and stability of the overall analyzer.

[0051] Such as figure 1 As shown, the enrichment system includes reagent bottle 1, first peristaltic pump 2, liquid storage bottle 3, second peristaltic pump 4, waste liquid bottle 5, third peristaltic pump 6, multi-way valve 7, solenoid valve 8, liquid flow rate Meter 9, enrichment pool 10, gas washing glass tube 11, sampling valve 12, particle filter 13, gas outlet glass tube 14, photoelectric switch 15, condensing reflux device 16, tail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com