Integrated photoelectrical waveguide modulator with high efficient heat radiation structure and manufacturing method thereof

A technology of waveguide modulator and heat dissipation structure, which is applied in the field of laser communication, can solve the problems of cumbersome and complicated process and high requirements for the design of the new structure of the modulator, and achieve the effects of simple process, thermal drift suppression, and efficient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

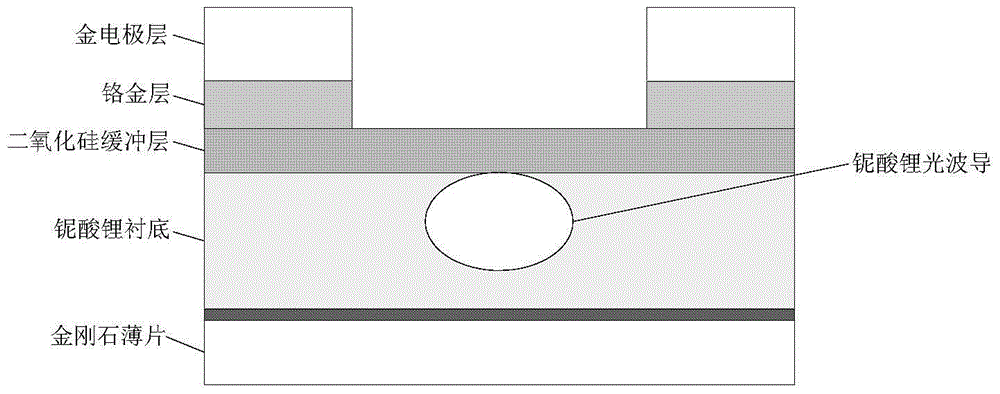

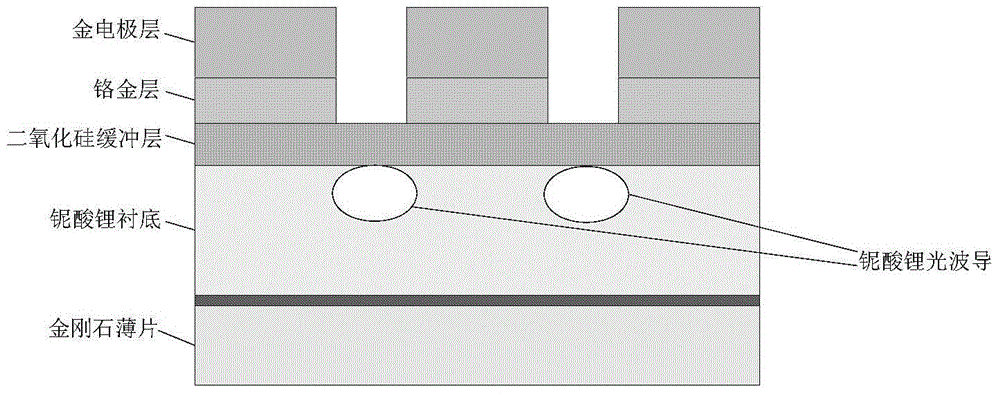

[0035] The size of the lithium niobate crystal selected in this embodiment is 40mm×10mm×2mm, the size of the diamond sheet is 40mm×10mm×1mm, the width of the lithium niobate optical waveguide in the electro-optic waveguide modulator component is 5-8 μm, gold The total thickness of the electrode layer and the chrome-gold layer is 6-15 μm.

[0036] In this embodiment, the specific implementation steps of preparing the integrated electro-optic waveguide modulator are given, including the steps of preparing the components of the electro-optic waveguide modulator and the steps of adding a heat dissipation structure, as follows:

[0037] (1), select an x-cut lithium niobate wafer with a size of 40mm×10mm×2mm;

[0038] (2), successively use absolute ethanol, acetone, trichlorethylene and deionized water to clean the wafer;

[0039] (3) After cleaning the wafer, use a pure nitrogen spray gun to blow the wafer, and the blowing direction of the air flow starts from the center of the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com