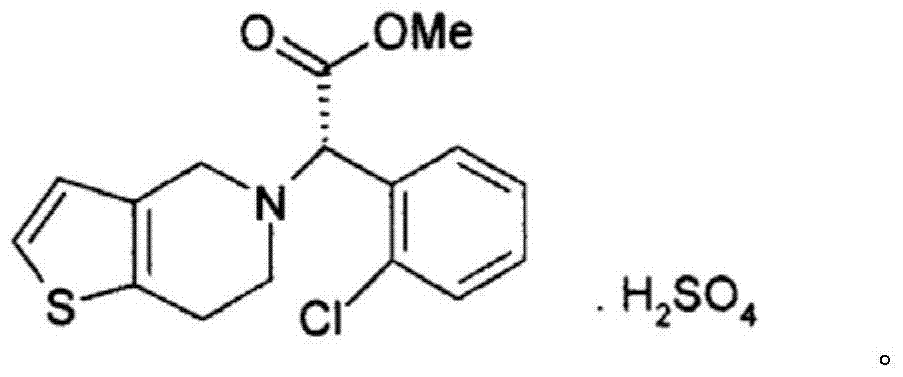

I type clopidogrel hydrogen sulfate particles and preparation method thereof as well as I type clopidogrel hydrogen sulfate solid preparation and preparation method thereof

A technology of clopidogrel hydrogen sulfate and granules, applied in the directions of pill delivery, pharmaceutical formulations, medical preparations of inactive ingredients, etc., can solve problems such as instability of type I clopidogrel hydrogen sulfate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

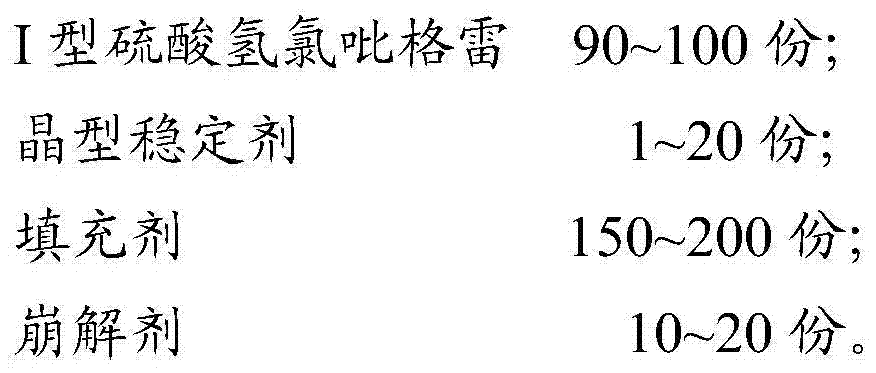

[0038] The invention provides a preparation method of type I clopidogrel bisulfate granules, comprising the following steps:

[0039] a), the crystal form stabilizer is mixed with a solvent to obtain a crystal form stabilizer solution; type I clopidogrel hydrogen sulfate is mixed with auxiliary materials to obtain a mixture;

[0040] The crystal form stabilizer is one or more of polyvinylpyrrolidone, copovidone and polyethylene glycol; the auxiliary material is a filler and / or a disintegrant;

[0041] b), the crystal form stabilizer solution and the mixture are sequentially mixed, granulated and dried to obtain type I clopidogrel hydrogen sulfate granules.

[0042] In the preparation method of type I clopidogrel bisulfate granules provided by the present invention, firstly, the crystal form stabilizer is mixed with a solvent to obtain a crystal form stabilizer solution. Wherein, the crystal form stabilizer is one or more of polyvinylpyrrolidone, copovidone and polyethylene gl...

Embodiment 1

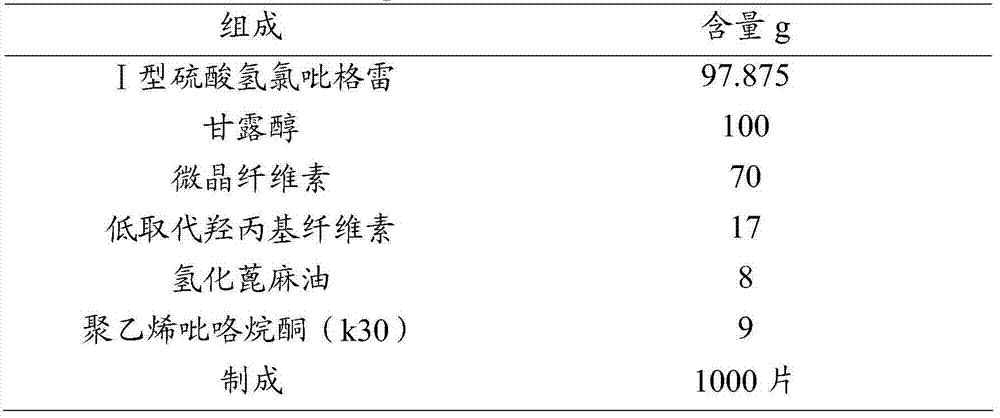

[0090] Prescription: Clopidogrel 75 mg / tablet

[0091]

[0092] Preparation Process:

[0093] 1) Mix 97.875g of clopidogrel hydrogen sulfate type I, 100g of mannitol, 70g of microcrystalline cellulose, and 17g of low-substituted hydroxypropyl cellulose to obtain a mixed material.

[0094] 2) Dissolving 9 g of polyvinylpyrrolidone (k30) in a small amount of ethanol to obtain a polyvinylpyrrolidone solution.

[0095] 3) Add polyvinylpyrrolidone solution to the mixed material to prepare soft material, which is granulated through a 24-mesh sieve in a swing granulator.

[0096] 4) The prepared granules were dried at 60° C. for 2 hours, then passed through a 18-mesh sieve for granulation, and 8 g of hydrogenated castor oil was added to the granulated granules, mixed evenly, and tableted to obtain a clopidogrel content of 75 mg / Tablets of 1000 tablets.

Embodiment 2

[0098] Prescription: Clopidogrel 75 mg / tablet

[0099]

[0100] Preparation Process:

[0101] 1) Mix 97.875g of clopidogrel hydrogen sulfate type I, 60g of mannitol, 120g of microcrystalline cellulose, and 12g of low-substituted hydroxypropyl cellulose to obtain a mixed material.

[0102] 2) Dissolving 6 g of polyvinylpyrrolidone (k90) in a small amount of ethanol to obtain a polyvinylpyrrolidone solution.

[0103] 3) Add polyvinylpyrrolidone solution to the mixed material to prepare soft material, which is granulated through a 24-mesh sieve in a swing granulator.

[0104] 4) The prepared granules were dried at 60° C. for 2 hours, then passed through a 18-mesh sieve for granulation, and 6 g of hydrogenated castor oil was added to the granulated granules, mixed evenly, and pressed into tablets to obtain a clopidogrel content of 75 mg / Tablets of 1000 tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com