Carbonized tail gas processing system of external heated rotary carbonization furnace and application method thereof

A technology of rotary carbonization furnace and carbonization tail gas, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, which can solve problems such as inconvenience in industrial production, blockage of tail gas pipelines, and difficulties in incinerator design, so as to improve utilization efficiency and prevent The effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

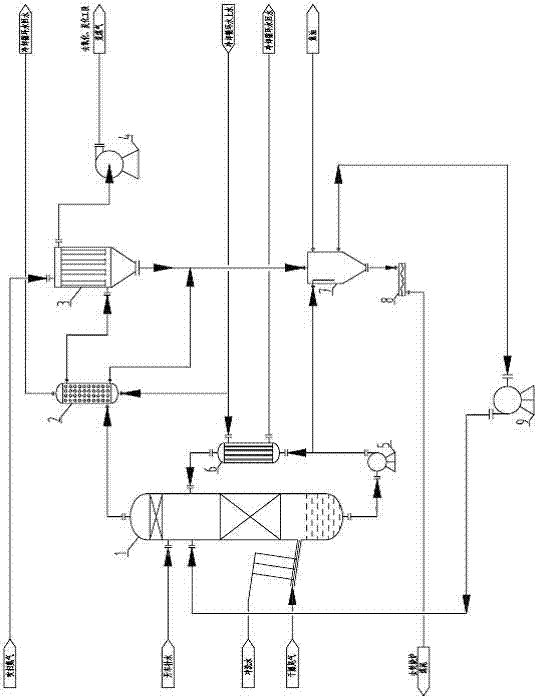

[0026] Such as figure 1 As shown, an externally heated rotary carbonization furnace carbonization tail gas treatment system includes a tail gas scrubber 1 , a tail gas heat exchanger 2 , an electric tar trap 3 , a cooler 6 , and a settling tank 7 . Wherein the tail gas heat exchanger 2 refers to a shell and tube heat exchanger or a coil heat exchanger.

[0027] One side of the tail gas scrubber 1 is respectively equipped with a start-up water supply pipeline, pipeline I, several flushing water pipelines with nozzle branch pipes, and a downward-sloping dry carbonization tail gas pipeline, and the other side passes through the pipeline II and the cooler 6. The top is connected, the top is connected to the tail gas heat exchanger 2 through the pipeline III, and the bottom is connected to the pipeline V through the tower bottom circulation pump 5 through the pipeline IV; the end of the nozzle branch pipe is inserted into the dry carbonization tail gas pipeline; the pipeline V is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com