Nano iron-carbon composite powder preparation method

A technology of carbon composite powder and nano-iron, which is applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of unsuitability for industrial production, high requirements for reaction conditions, complex equipment, etc., and achieve low cost, simple equipment, The effect of lowering the reduction reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

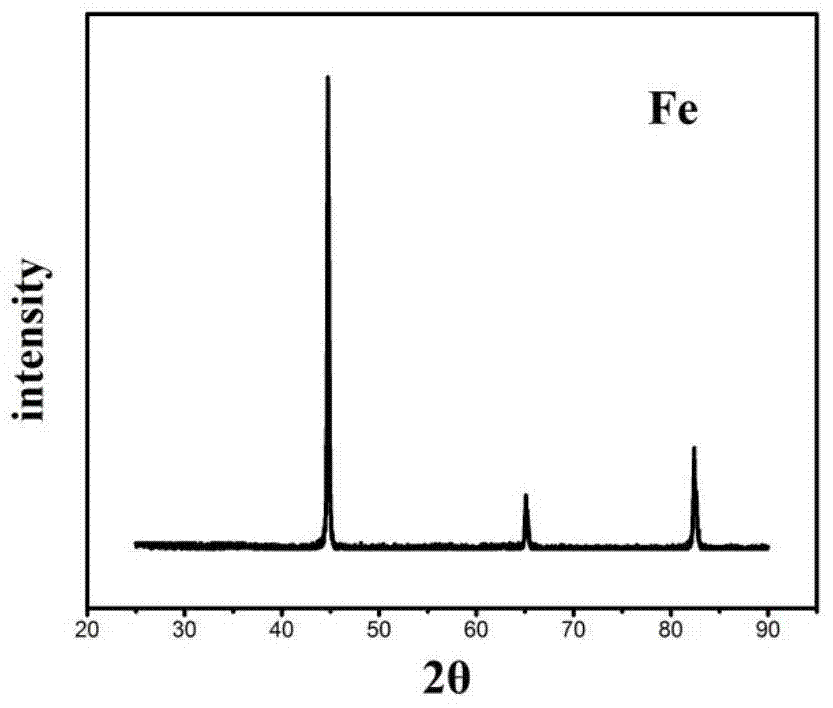

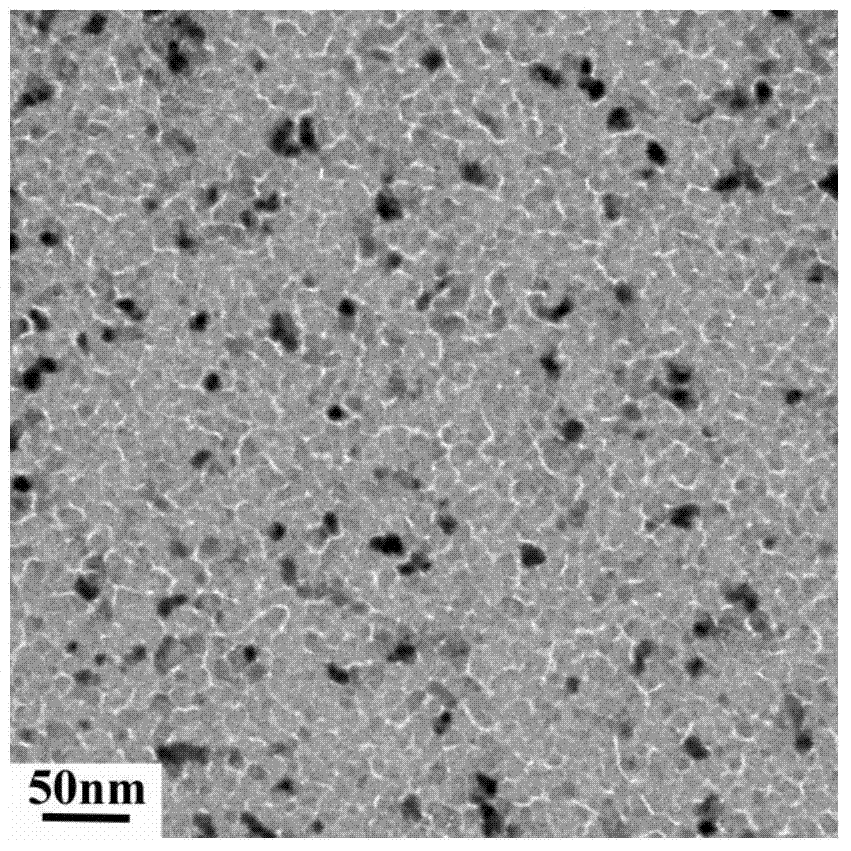

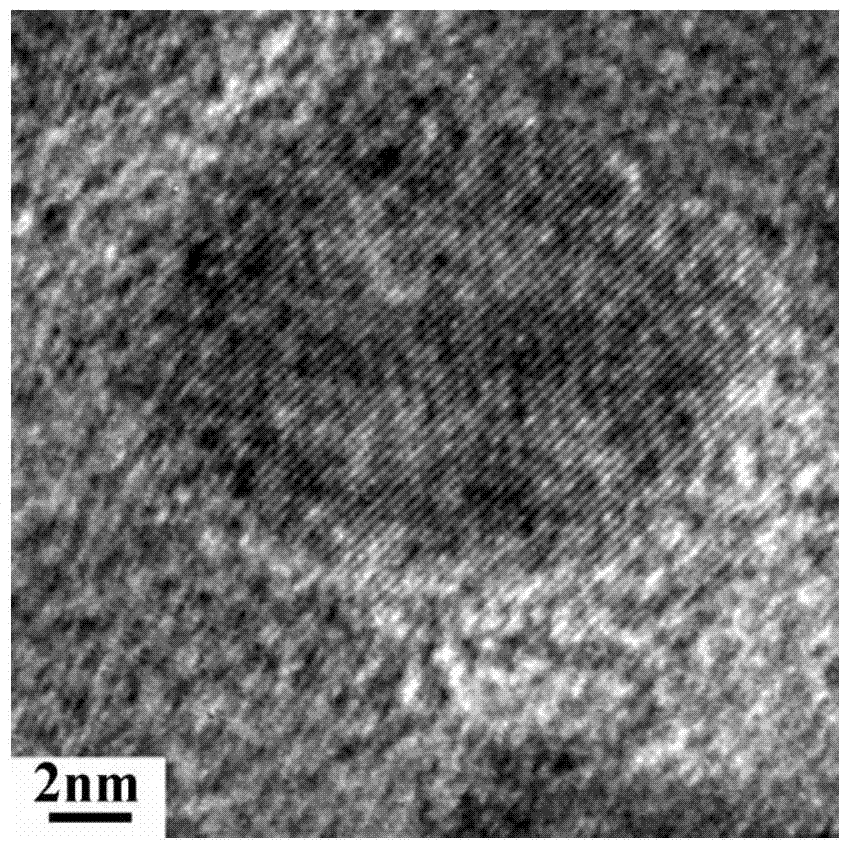

[0025] Weigh 0.025 moles of ferric nitrate, 0.06 moles of glycine (reducing agent), and 0.04 moles of glucose (carbon source), dissolve various raw materials in deionized water, and prepare a solution; the solution is placed on a temperature-controllable electric furnace for heating, and the solution After a series of reactions such as volatilization, concentration, and decomposition, the precursor powder is obtained; in a hydrogen atmosphere, the precursor powder is placed in a furnace at 300°C for 2 hours to obtain a nano-iron-carbon composite powder.

Embodiment 2

[0027] Weigh 0.025 moles of ferric nitrate, 0.075 moles of glycine (reducing agent), and 0.05 moles of glucose (carbon source), dissolve various raw materials in deionized water, and prepare a solution; the solution is placed on a temperature-controllable electric furnace for heating, and the solution After a series of reactions such as volatilization, concentration, and decomposition, the precursor powder is obtained; in a hydrogen atmosphere, the precursor powder is placed in a furnace at 400°C for 2 hours to obtain a nano-iron-carbon composite powder.

Embodiment 3

[0029] Weigh 0.025 moles of ferric nitrate, 0.05 moles of alanine (reducing agent), and 0.04 moles of maltose (carbon source), dissolve various raw materials in deionized water, and prepare a solution; place the solution on a temperature-controllable electric furnace for heating , After the solution undergoes a series of reactions such as volatilization, concentration, and decomposition, the precursor powder is obtained; in a hydrogen atmosphere, the precursor powder is placed in a furnace at 500°C for 2 hours to obtain a nano-iron-carbon composite powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com