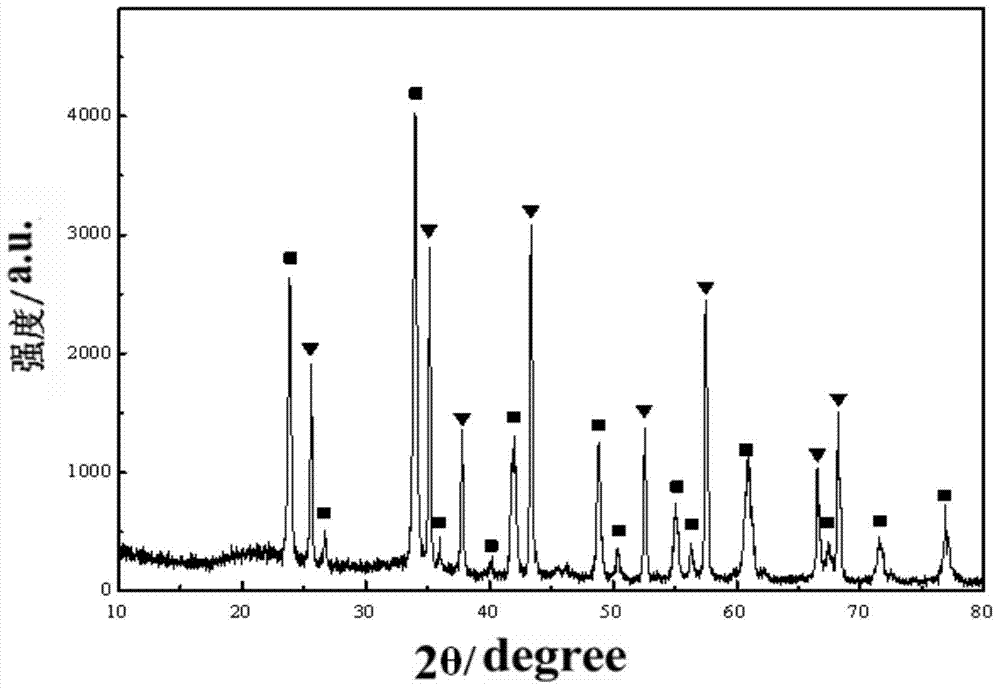

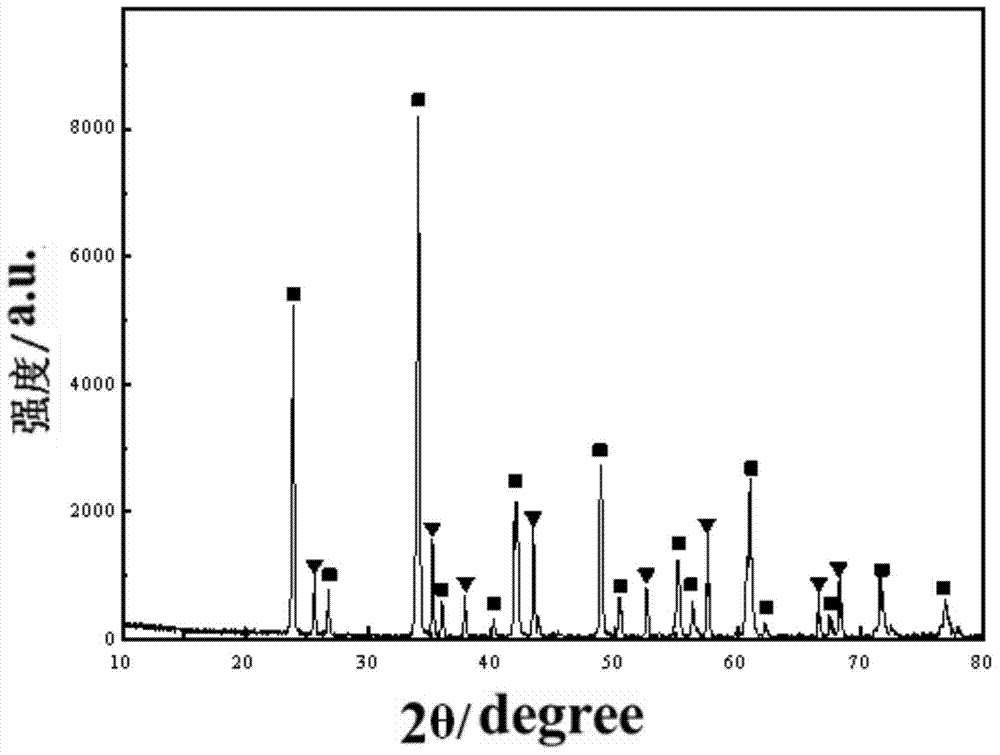

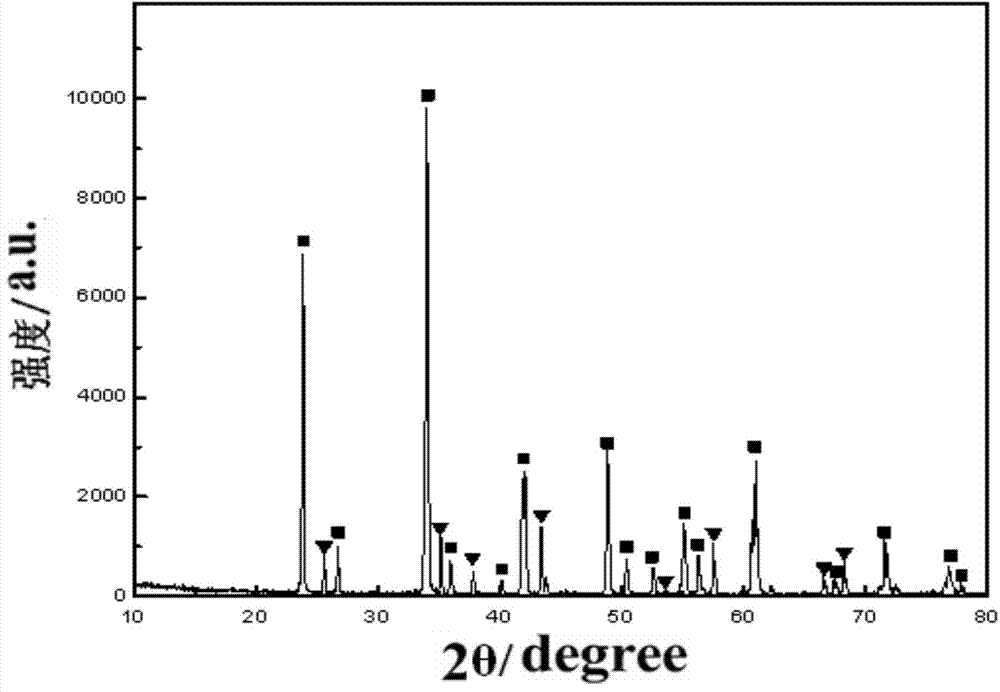

Preparation method of nanometer aluminum oxide/ gadolinium-aluminum perovskite composite powder

A nano-alumina and composite powder technology, which is applied in the field of preparation of nano-alumina/gadolinium aluminate composite powder, can solve the problem that the sol-gel method is not suitable for large-scale synthesis, the combustion synthesis method reacts quickly and is difficult to control, and the equipment Require high-level problems, achieve the effect of low production cost, simple preparation method, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific implementation mode 1: This implementation mode is a preparation method of nano-alumina / gadolinium aluminate composite powder, which is specifically carried out according to the following steps:

[0020] 1. Preparation of gadolinium nitrate solution: dissolve gadolinium oxide in concentrated nitric acid, and heat at a temperature of 20°C to 120°C until gadolinium oxide is completely dissolved to obtain a gadolinium nitrate solution; the quality of the gadolinium oxide is the same as that of concentrated nitric acid The volume ratio is 1g:(1mL~27.6mL);

[0021] Two, prepare aluminum nitrate solution: aluminum nitrate nonahydrate is dissolved in distilled water, obtain aluminum nitrate solution; The quality of described aluminum nitrate nonahydrate and the volume ratio of distilled water are 1g: (1.33mL~26.66mL);

[0022] 3. Co-precipitation: uniformly mix the gadolinium nitrate solution prepared in step 1 and the aluminum nitrate solution prepared in step 2 to o...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment differs from Embodiment 1 in that: the mass fraction of concentrated nitric acid described in step 1 is 65% to 68%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: this embodiment is different from one of specific embodiments one to two in that: the mass of gadolinium oxide described in step one and the volume ratio of concentrated nitric acid are 1g:(3mL~15mL). Others are the same as one of the specific embodiments 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com