Narrow-linewidth and low-loss gyromagnetic ferrite material and preparation method thereof

The invention relates to a technology of spinning ferrite and low loss, which is applied in the field of narrow linewidth and low loss spinning ferrite material and its preparation field, and can solve the problem of limiting the mass production and preparation of narrow linewidth spinning ferrite material, high cost of raw and auxiliary materials, high cost of raw and auxiliary materials, etc. Complex composition and other problems, to achieve the effect of good mechanical properties, less defects, uniform and complete grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

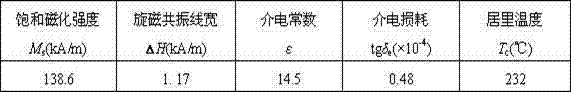

Embodiment 1

[0039] A narrow linewidth and low loss gyromagnetic ferrite material, its main phase is garnet, and its chemical formula is Y 3-x Ca x Fe 5-x-3y Li y Sn 2y+x O 12 , where: x=0.06; y=0.008. The preparation method of this gyromagnetic ferrite material is as follows:

[0040] According to the chemical formula Y 3-x Ca x Fe 5-x-3y Li y Sn 2y+x O 12 , where: x=0.06, y=0.008, calculate and weigh the required raw materials. The raw material used is Fe 2 O 3 (purity >99.2%), Y 2 O 3 (purity >99.5%), CaCO 3 (analytical grade), LiCO 3 (analytical grade), SnO 2 (analytically pure). Fe in the raw material formula 2 O 3 Compared with the calculated results, the dosage of 2-3 wt% was reduced.

[0041] Load the weighed raw materials into the hopper of the vibrating mill, and add Φ15 mm chromium steel balls in the ratio of material: ball = 1:5 for dry vibrating and mixing for 0.5 hours.

[0042] The mixed material was put into a zirconia crucible, and then put into a bo...

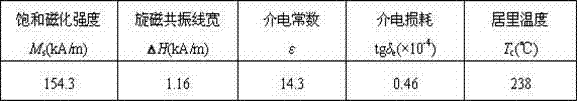

Embodiment 2

[0054] A narrow linewidth and low loss gyromagnetic ferrite material, its main phase is garnet, and its chemical formula is Y 3-x Ca x Fe 5-x-3y Li y Sn 2y+x O 12 , where: x=0.08; y=0.01. The preparation method of this gyromagnetic ferrite material is as follows:

[0055] According to the chemical formula Y 3-x Ca x Fe 5-x-3y Li y Sn 2y+x O 12 , where: x=0.08, y=0.01, calculate and weigh the required raw materials. The raw material used is Fe 2 O 3 (purity >99.2%), Y 2 O 3 (purity >99.5%), CaCO 3 (analytical grade), LiCO 3 (analytical grade), SnO 2 (analytically pure). Fe in the raw material formula 2 O 3 Compared with the calculated results, the dosage of 2-3 wt% was reduced.

[0056] Load the weighed raw materials into the hopper of the vibrating mill, and add Φ15 mm chromium steel balls in the ratio of material: ball = 1:5 for dry vibrating and mixing for 0.5 hours.

[0057] The mixed material was put into a zirconia crucible, and then put into a box ...

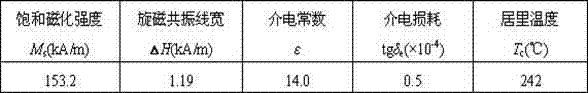

Embodiment 3

[0069] A narrow linewidth and low loss gyromagnetic ferrite material, its main phase is garnet, and its chemical formula is Y 3-x Ca x Fe 5-x-3y Li y Sn 2y+x O 12 , where: x=0.1; y=0.006. The preparation method of this gyromagnetic ferrite material is as follows:

[0070] According to the chemical formula Y 3-x Ca x Fe 5-x-3y Li y Sn 2y+x O 12 , where: x=0.1, y=0.006, calculate and weigh the required raw materials. The raw material used is Fe 2 O 3 (purity >99.2%), Y 2 O 3 (purity >99.5%), CaCO 3 (analytical grade), LiCO 3 (analytical grade), SnO 2 (analytically pure). Fe in the raw material formula 2 O 3 Compared with the calculated results, the dosage of 2-3 wt% was reduced.

[0071] Load the weighed raw materials into the hopper of the vibrating mill, and add Φ15 mm chromium steel balls in the ratio of material: ball = 1:5 for dry vibrating and mixing for 0.5 hours.

[0072] The mixed material was put into a zirconia crucible, and then put into a box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com