Method for separating two bibenzyl compounds from ordinary oil tea camellia

A common oil and separation technology, applied in the preparation of organic compounds, chemical instruments and methods, sugar derivatives, etc., can solve problems such as difficulty, unsuitability for industrial applications, and difficulty in separating complex samples with pressurized thin layers. The preparation process is simple and the extraction rate is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

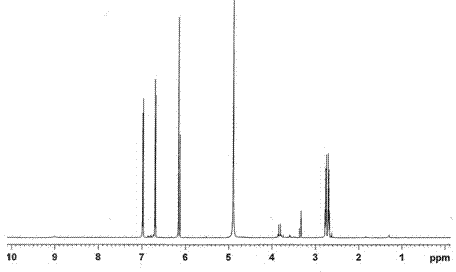

[0057] Extraction of Compound 1 from Common Camellia oleifera:

[0058] (1) Raw material preparation: Fresh oil tea leaves are collected from Tianjiling National Forest Park in Hunan Province, and identified as ordinary oil tea leaves (Camellia Oleifera Abel.) by Professor Tan Xiaofeng of Central South University of Forestry and Technology; the ordinary oil tea leaves are washed and destemmed, naturally air-dried, and crushed Finally, 20kg of samples were obtained;

[0059] (2) Extraction: Use 60 L of ethanol solution with a volume fraction of 50%, leaching twice at 70°C for 2 hours each time, filter the extract, and depressurize the extract at 40°C and a vacuum of 0.08MPa Concentrate, and concentrate until the volume is 30% of that before concentration to obtain a concentrated solution;

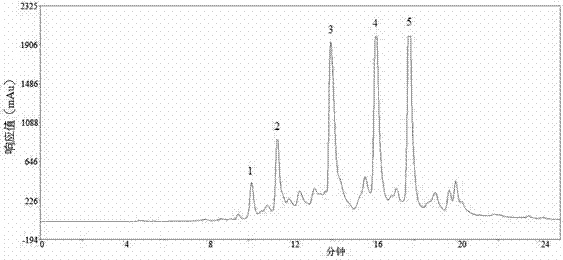

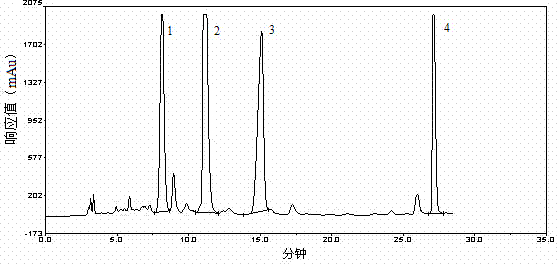

[0060] (3) Separation and purification: pass the concentrated solution of 3BV obtained in step (2) through D-101 macroporous resin. 3BV of distilled water, 6BV of ethanol solution with a...

Embodiment 2

[0091] Extraction of Compound 1 from Common Camellia oleifera:

[0092] (1) Raw material preparation: Fresh oil tea leaves are collected from Tianjiling National Forest Park in Hunan Province, and identified as ordinary oil tea leaves (Camellia Oleifera Abel.) by Professor Tan Xiaofeng of Central South University of Forestry and Technology; the ordinary oil tea leaves are washed and destemmed, naturally air-dried, and crushed Finally, 20kg of samples were obtained;

[0093] (2) Extraction: Use 40L of ethanol solution with a volume fraction of 60%, extract 3 times at 60°C for 2 hours each time, filter the extract, and concentrate the extract under reduced pressure at 50°C and a vacuum of 0.09MPa , concentrated to a volume of 35% before concentration to obtain a concentrated solution;

[0094] (3) Separation and purification: pass the concentrated solution of 3BV obtained in step (2) through D-101 macroporous resin, wherein the amount of macroporous resin is 9L, and the diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com