Acrylate adhesive for yacht industry

A technology of acrylate and adhesive, which is applied in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc. It can solve the problems of large main component, reduced bonding strength, seawater salt spray resistance, and volatilization. Achieve the effect of good bonding strength and good resistance to seawater and salt spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

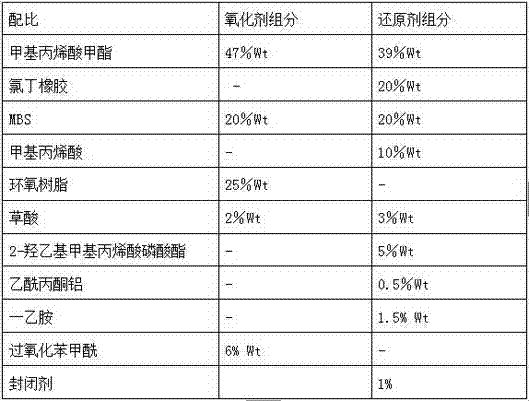

[0030] Table 1:

[0031]

[0032] In this embodiment, the sealing agent is composed of 40% acrylate-modified butadiene resin with a melting point between 47°C and 64°C and 60% polyvinyl alcohol with a melting point between 47°C and 64°C.

[0033] In this example, the oxidizing agent component and the reducing agent component were prepared at a volume ratio of 1:10 to prepare an acrylate adhesive.

[0034] 1. Preparation method:

[0035] (1) Oxidant component: add the acrylate monomer methyl methacrylate into the reaction kettle, add the elastomer MBS and stir until the elastomer is completely dissolved; then add epoxy resin and stabilizer oxalic acid and stir until evenly mixed; Finally, the initiator benzoyl peroxide is added and stirred until the mixture is uniform, and the preparation is completed after vacuuming.

[0036] (2) Reductant component: add acrylate monomer methyl methacrylate and methacrylic acid into the reaction kettle, add elastomer neoprene and...

Embodiment 2

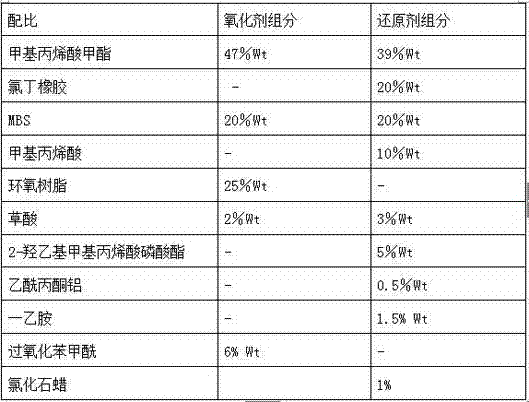

[0044] Table 2:

[0045]

[0046] In this embodiment, the blocking agent is the same as in Embodiment 1.

[0047] The preparation method and performance test of this example are the same as those of Example 1; in this example, the acrylate adhesive is prepared with a volume ratio of the oxidizing agent component and the reducing agent component being 1:10.

Embodiment 3

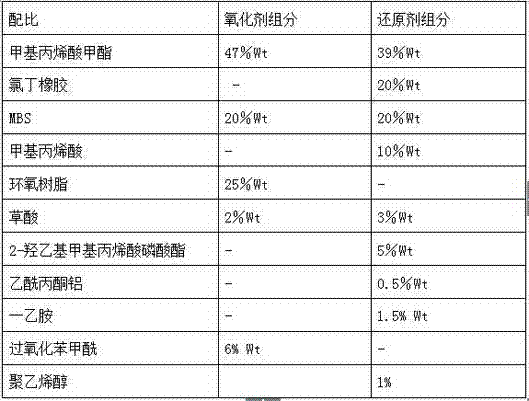

[0049] table 3:

[0050]

[0051] In this embodiment, the sealing agent is composed of 60% acrylate-modified butadiene resin with a melting point between 47°C and 64°C and 40% polyvinyl alcohol with a melting point between 47°C and 64°C.

[0052] The preparation method and performance test of this example are the same as those of Example 1; in this example, the acrylate adhesive is prepared with a volume ratio of the oxidizing agent component and the reducing agent component being 1:10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com