Slagging method of sintering return mines of continuous steelmaking electric furnace

A technology of sintering and returning to ore and electric furnace sintering, which is applied in the field of steelmaking, can solve the problems of affecting production cost, high cost of slagging materials, furnace lining refractory materials, smoke hood erosion, etc., and achieve the goal of reducing the melting point of slag, promoting the formation and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Before the implementation of a steel factory, the cost of fluorite consumption per ton of steel in 2011 was 5.98 yuan / t (calculated at the price of 1200 per ton of fluorite). 800 yuan / t, the cost is 10×800 / 1000=8 yuan / t. At the same time, because the sintered ore contains TFe: 57.36 (%), through comparative analysis of the slag, the TFe content of the slag before the sintered ore is 14.77%, and the TFe content of the slag after the sintered ore is 17.56%. Reduce the consumption of steel materials by 5kg / t, and the unit price of scrap steel is calculated as 2500 yuan / t, and the cost saving per ton of steel is 5×2500× / 1000=12.5 yuan / t. The total saving cost per ton of steel is: 12.5+5.98-8=10.48 yuan / t. Social benefits: make full use of resources, realize resource conservation, and comply with national policies.

Embodiment 2

[0025] A certain amount of sintering and returning ore was added to four Consteel electric furnaces numbered 107782, 107783, 107784 and 107785 respectively, and the work was carried out according to the steps in the above-mentioned continuous steelmaking electric furnace sintering and returning to ore slagging method, and the following parameters were measured:

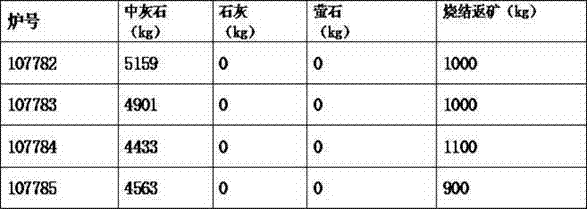

[0026] The situation of the sintering return of the four Consteel electric furnaces is as follows:

[0027]

[0028] And use this method Consteel electric furnace slagging material consumption:

[0029]

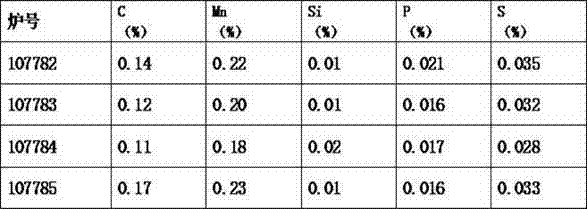

[0030] The final sample composition of HRB335 steel grade smelted by Consteel electric furnace after using this method

[0031]

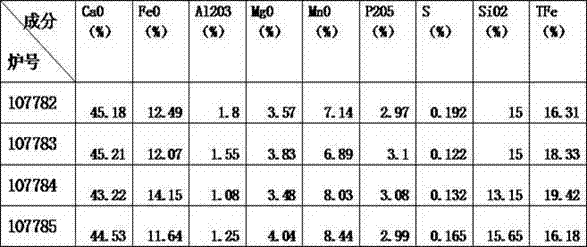

[0032] Composition of slag using this method

[0033]

[0034] The above heat test results show that the use of sintering and slagging as a slag-forming agent can fully meet the smelting requirements, but after popularization and use, the monthly consumption of steel materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com