A PECVD coating process for preparing component crystalline silicon solar cells

A solar cell and process technology, which is applied in metal material coating process, sustainable manufacturing/processing, circuit, etc., can solve the problems of battery sheet efficiency drop, lack of hydrogen passivation effect, etc., and achieve conversion efficiency without drop, The scheme is simple and feasible, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

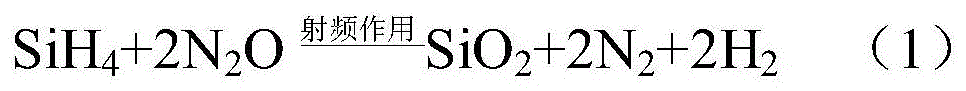

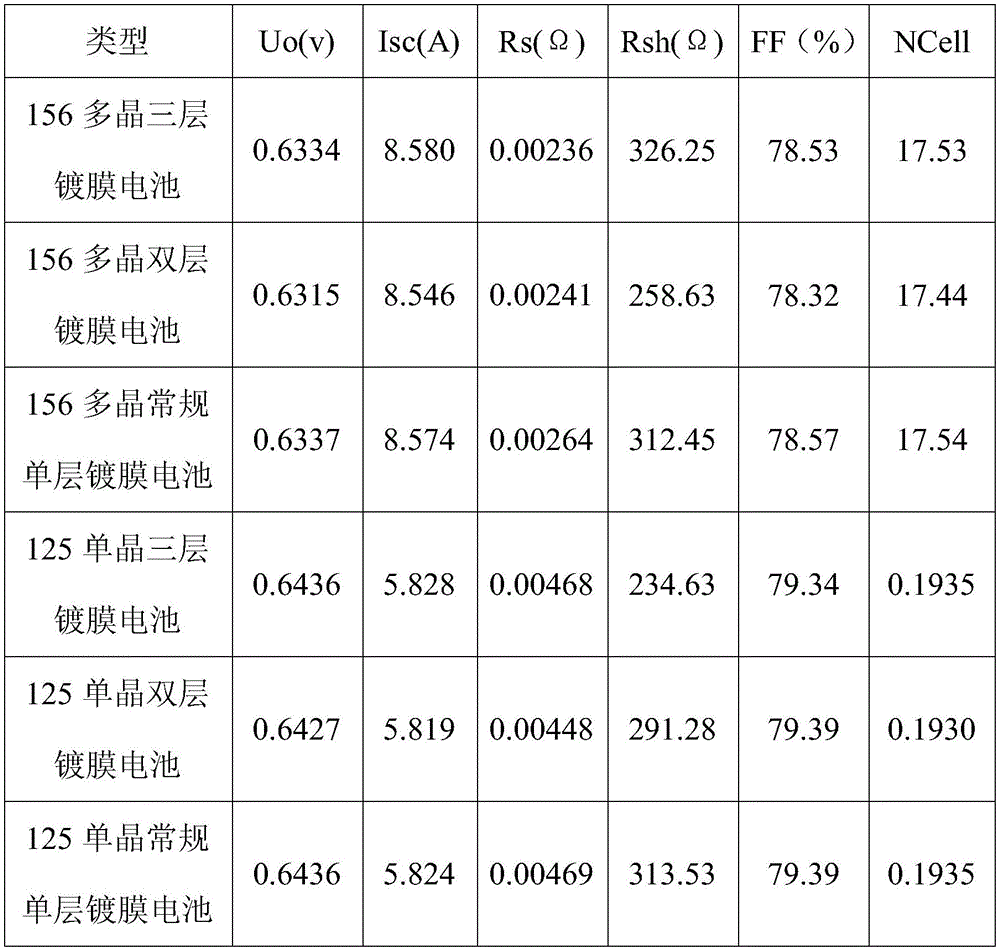

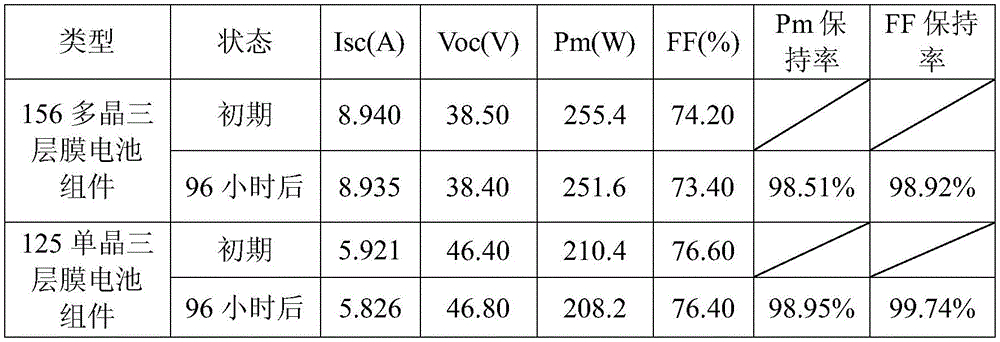

[0027] The P-type 156 polysilicon wafers are successively subjected to several processes of acid texturing, diffusion, and wet etching cleaning. According to the scheme of the present invention, silicon nitride-silicon dioxide-nitrogen is prepared in a tubular PECVD furnace tube. Silicon nitride laminated film; the specific process for preparing the inner silicon nitride film is: SiH 4 The flow rate is 1000sccm, and NH is fed 3 The flow rate is 5000sccm, the pressure in the furnace tube is set at 1700mTorr, the temperature is set at 450°C, the radio frequency power is set at 3000W, and the coating time is set at 30s to obtain an inner silicon nitride film with a film thickness of 10nm and a refractive index of 2.1; then prepare the intermediate layer of silicon dioxide film, the specific process is: SiH 4 The flow rate is 1000sccm, through N 2 The O flow rate is 2500 sccm; the pressure in the furnace tube is set at 1700mTorr, the temperature is set at 450°C, and the radio fr...

Embodiment 2

[0029] The P-type 125 monocrystalline silicon wafers are sequentially subjected to several processes of alkali texturing, diffusion, and dry etching cleaning. According to the scheme of the present invention, silicon nitride—silicon dioxide—is prepared in a tubular PECVD furnace tube. —Silicon nitride laminated film; the specific process for preparing the inner silicon nitride film is: SiH 4 The flow rate is 1000sccm, and NH is fed 3 The flow rate is 4500sccm, the pressure in the furnace tube is set at 1700mTorr, the temperature is set at 450°C, the radio frequency power is set at 3000W, and the coating time is set at 20s to obtain an inner silicon nitride film with a film thickness of 6nm and a refractive index of 2.1; then prepare the intermediate layer of silicon dioxide film, the specific process is: SiH 4 The flow rate is 1000sccm, through N 2 The flow rate of O is 2000sccm; the pressure in the furnace tube is set at 1700mTorr, the temperature is set at 450°C, and the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com