Gob-side entry retaining method capable of avoiding dynamic pressure influence on coal mining

A technology of retaining roadways and coal seams, which is applied in ground mining, mining equipment, earthwork drilling and mining, etc. It can solve the problems of increased difficulty in safety management of shed repairs, a large amount of material and labor costs, repeated investment of I-beams, etc., and achieves increased Cost and engineering quantity, reduce the cost of roadway retention, and the effect of roadway stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

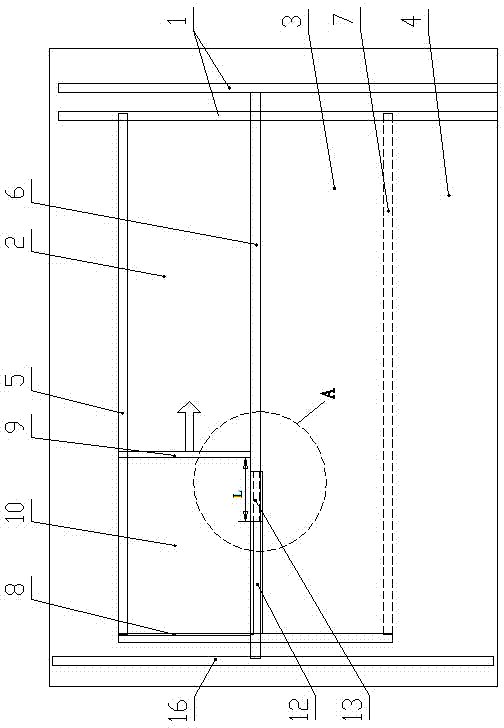

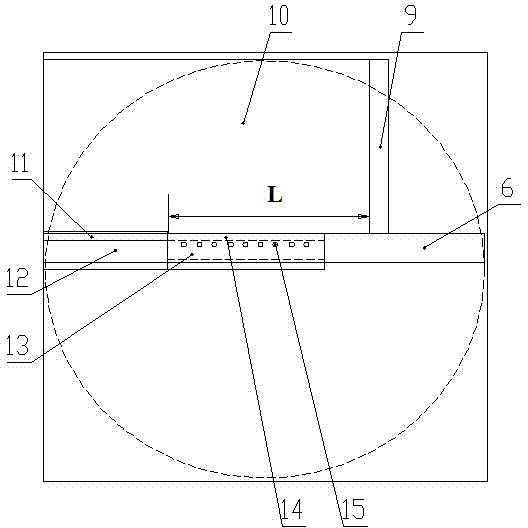

[0030] Such as figure 1 with figure 2 As shown, the coal seam mining of the present invention avoids the gob-side entry method of dynamic pressure influence, comprises the following steps:

[0031] 1) Divide the coal seam into the mining area, and divide the mining area into several sections, arrange the preparation roadway 1 serving each section in the mining area, and the leftmost side behind the preparation roadway 1 is the first section 2, The right side of the first section 2 is the second section 3, the right side of the second section 3 is the third section 4, and so on, and the rightmost side of the preparation roadway 1 is the Nth section;

[0032] 2) On the left side of the first section 2, there is a return air level roadway 5 in the first section that is perpendicular to and connected with the preparation roadway 1. Between the first section 2 and the second section 3, there is a vertical roadway 5 perpendicular to the preparation roadway 1. The first section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com