Method for measuring diffusion coefficient and equilibrium concentration of CO2 in process of diffusion from water phase to oil phase

A technology of diffusion coefficient and equilibrium concentration, used in measuring devices, specific gravity measurement, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

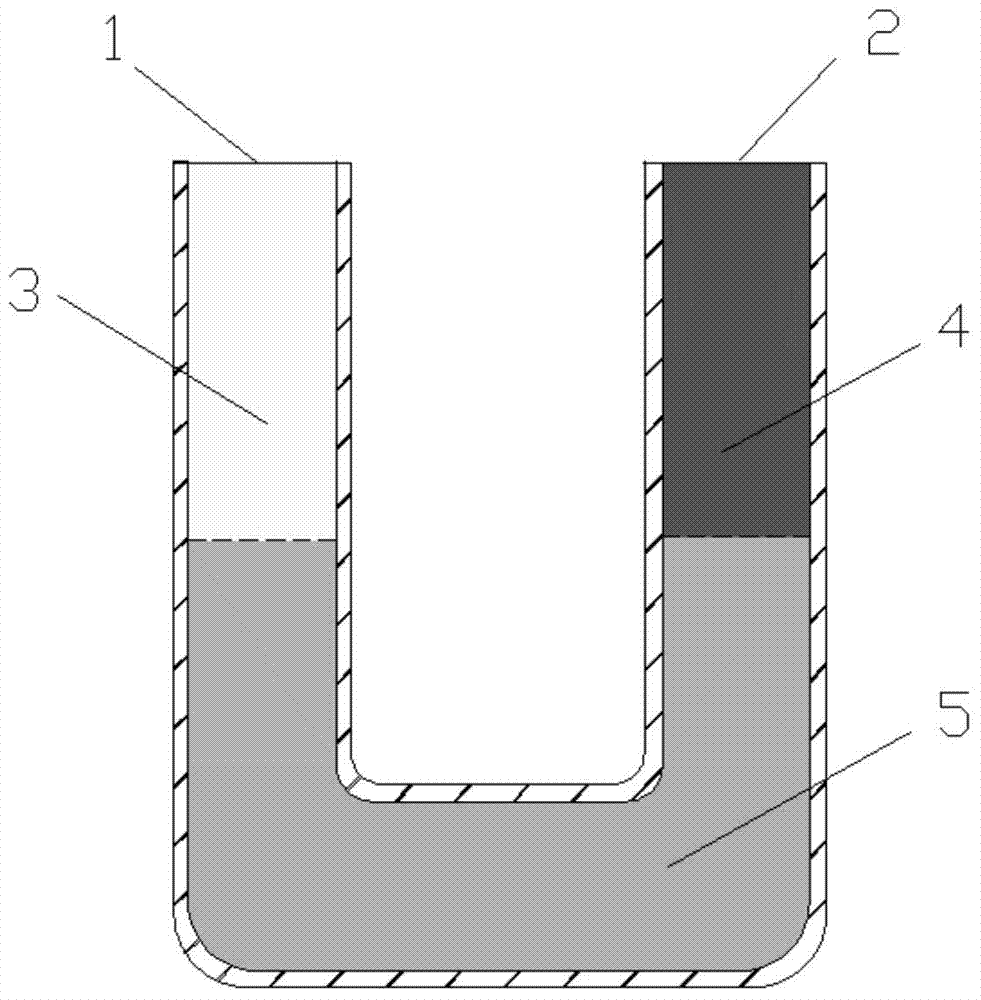

[0064] a CO 2 Method for measuring diffusion coefficient and equilibrium concentration during diffusion from water phase to oil phase, wherein the implementation of the method is applied to a measuring device, the measuring device includes a vertically fixed U-shaped tube, and the U-shaped tube includes a terminal 1 and b-end 2, both the a-end 1 and the b-end 2 are open upwards; the specific steps include:

[0065] (1) Measure the volume V of the U-shaped tube 1 250mL and the cross-sectional area A of the inner diameter of the U-shaped tube 1 8cm 2 , check the airtightness of the whole measuring device;

[0066] (2) Inject distilled water with a temperature of T into the U-shaped tube, so that the U-shaped tube is filled with distilled water, and the value of T is 50°C;

[0067] (3) Connect the back pressure valve connected to the back pressure pump to the b-end 2 of the U-shaped pipe to communicate with the back pressure, and the back pressure pump is set to a predetermin...

Embodiment 2

[0093] According to the measurement method described in Embodiment 1, the difference is that the measurement device also includes COs that are respectively movably connected with the U-shaped tubes. 2 Gas tanks, distilled water tanks and crude oil tanks, the CO 2 The gas tank, the distilled water tank and the crude oil tank are respectively connected with advection pumps.

[0094] CO 2 CO in the tank 2 , the distilled water in the distilled water tank and the crude oil in the crude oil tank are respectively pumped into the U-shaped pipe.

Embodiment 3

[0096] According to the measurement method described in embodiment 1 or 2, the difference is that CO is injected into the U-shaped tube 2 , distilled water and crude oil, the CO 2 The gas tank, the distilled water tank, the crude oil tank and the U-shaped pipe are vacuumed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com