Optical measuring system used for measuring field intensity of direct-current electric field

An optical measurement system and field strength measurement technology, applied in electrostatic field measurement and other directions, can solve problems such as difficult to apply to industrial sites, limited application scope, sophisticated and complex equipment, etc., to improve accuracy and reliability, not easy to electromagnetic interference, increase The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

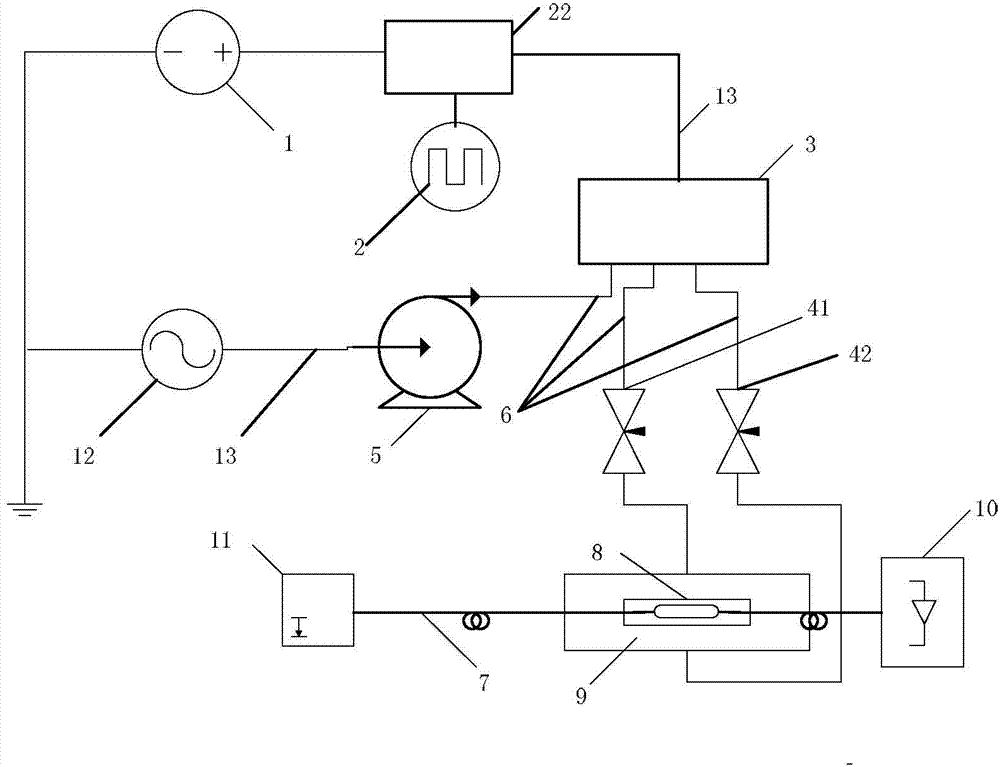

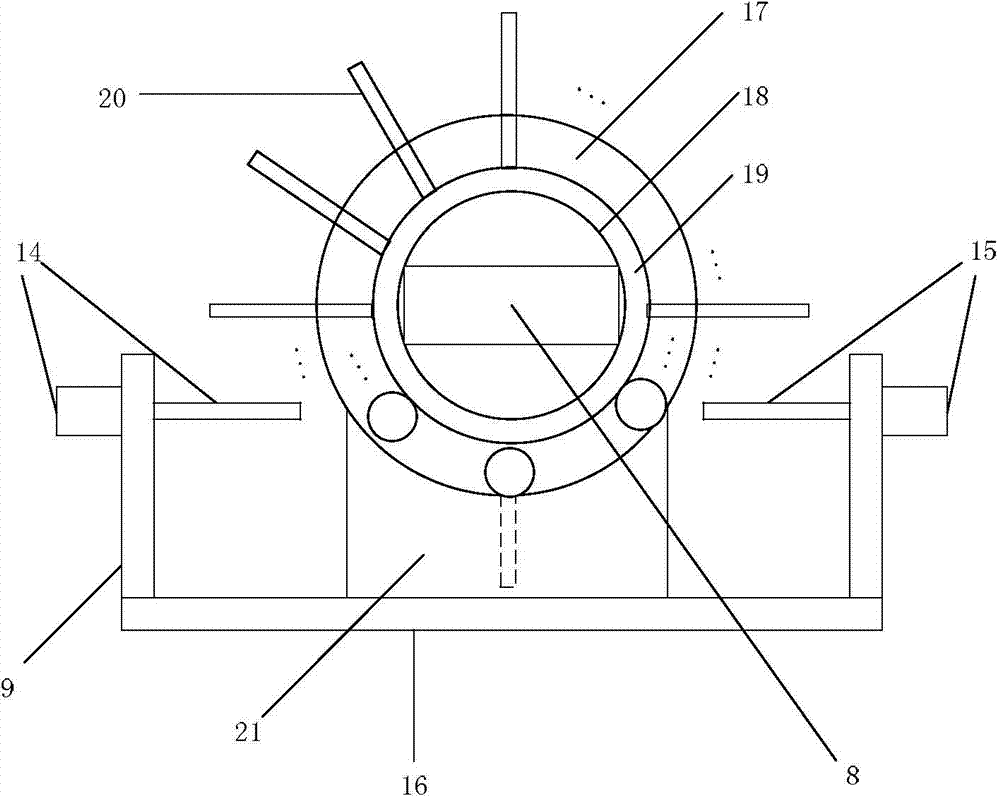

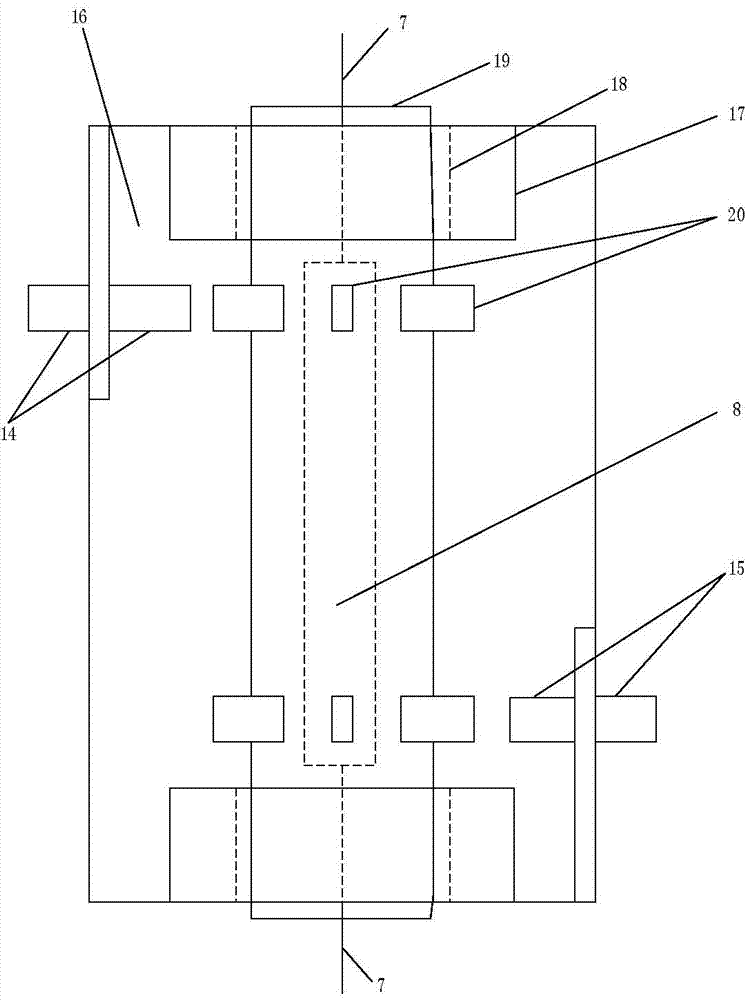

[0014] The optical measurement system for the measurement of the DC electric field intensity proposed by the present invention has a structural schematic diagram as figure 1 As shown, it includes a DC power supply 1, a signal generator 2, a signal drive circuit 22, an electromagnetic reversing valve 3, a first throttle valve 41, a second throttle valve 42, an AC power supply 12, an electric air pump 5, a laser source 11, Rotary device 9 , electric field sensor 8 and detector 10 . The DC power supply 1 and the signal generator 2 are respectively connected to a signal driving circuit 22 . The AC power supply 12 is connected to the input end of the electric air pump 5 through a signal line, and the output end of the electric air pump 5 is connected to the air intake end of the electromagnetic reversing valve 3 through the gas pipeline 6, and the two gas outlets of the electromagnetic reversing valve 3 are respectively connected to the The intake port of the first throttle valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com