Non-magnetic heating device for nuclear magnetic resonance gyroscope

A nuclear magnetic resonance gyro and magnetic heating technology, which is applied in the direction of electric heating devices, ohmic resistance heating, steering induction equipment, etc., can solve the problems of inability to use miniature nuclear magnetic resonance gyroscopes, excessive transverse magnetic field gradients in gas chambers, and reduced transverse relaxation time, etc. problems, to achieve uniform heating, good thermal insulation performance, and reduce power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

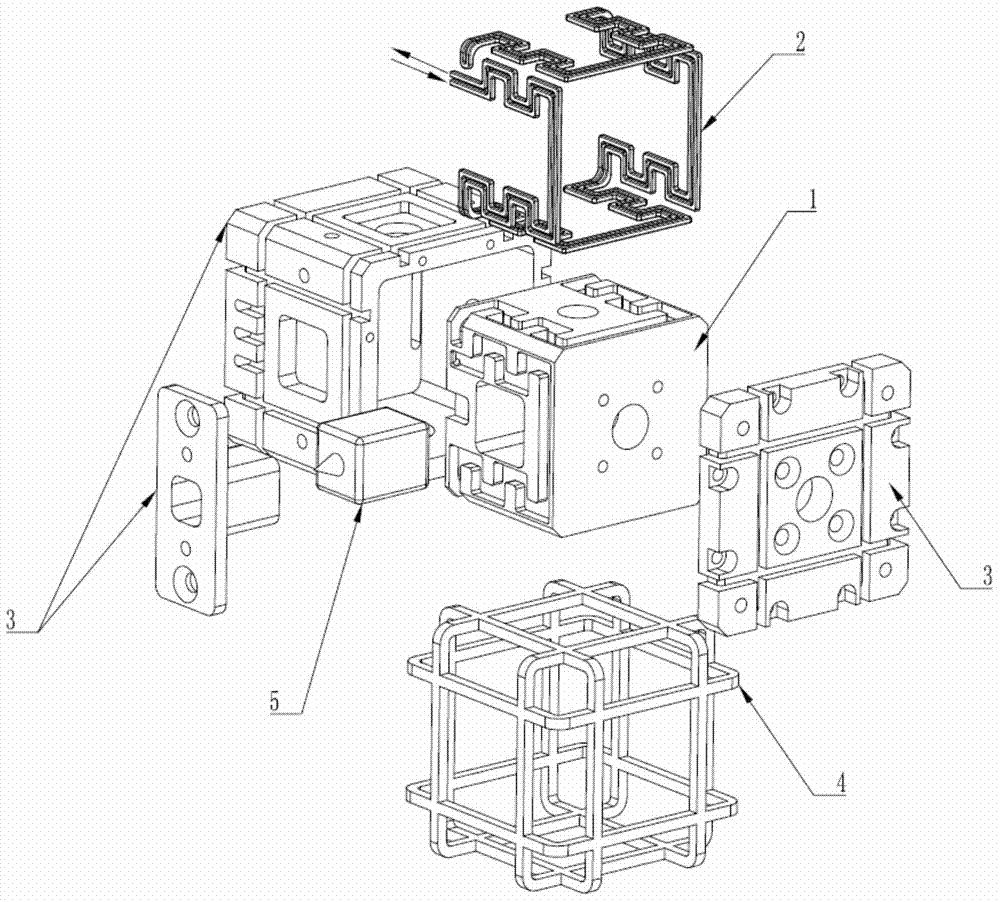

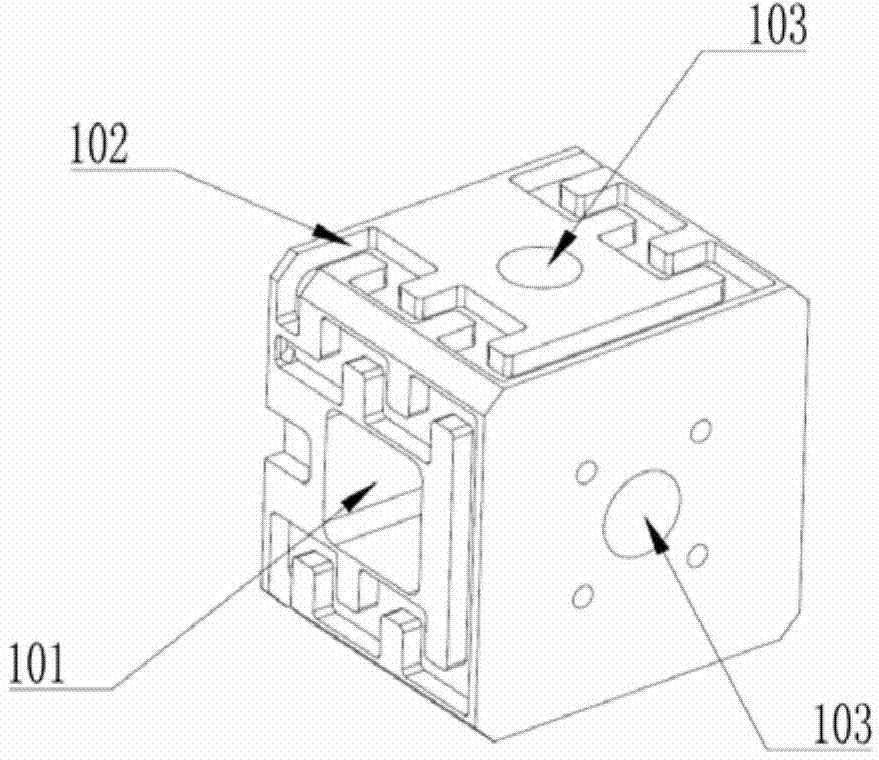

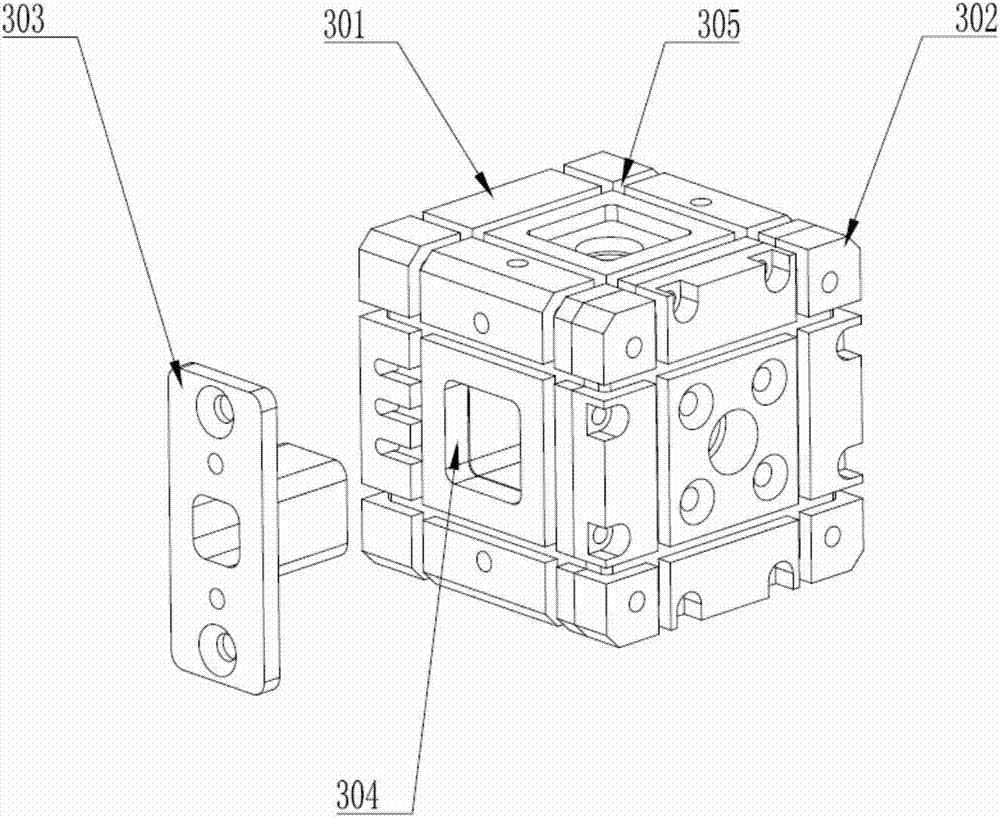

[0044] A non-magnetic heating device for nuclear magnetic resonance gyroscopes, wherein the heating body is made of T2 red copper with a thermal conductivity of 401W / (m.℃). The structure of the heating body is hollow, with a square hole on one side, which can be Put the atomic gas chamber into the inside of the heating body through the square hole. Heating grooves are arranged on four surfaces outside the heating body. The heating wire is made of nickel-chromium alloy heating wire with a total resistance of 3Ω. It is placed in the heating tank in the forward and reverse directions, and is routed under the constraints of the heating tank, forming a spatially symmetrical non-magnetic heating structure. In actual work, the heating current is 2A, and the total heating power is 12W. At the beginning of heating, the heating body is like a stove, which can heat 5 surfaces of the atomic gas chamber at the same time, with high heating efficiency, and the measured temperature differenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com