Aerobic solid-state fermentation system

A technology of solid fermentation and fermentation rack, applied in the field of fermentation system, can solve the problems of large workload, bacterial contamination, and complicated work in the artificial inoculation process, and achieve the effect of effectively utilizing internal space, preventing bacterial contamination, and simple layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

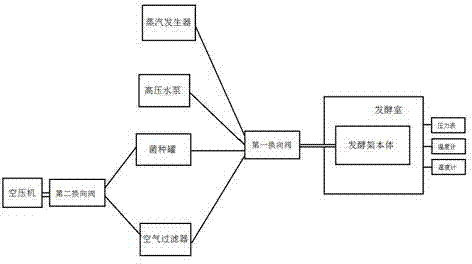

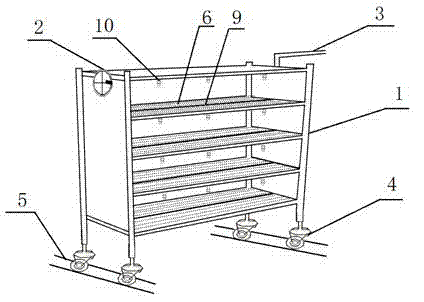

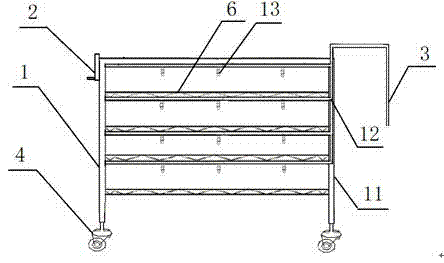

[0018] Such as Figure 1 to Figure 5 As shown, an aerobic solid fermentation system includes a fermentation rack body 1, a steam generator, a strain tank, a high-pressure water pump, an air filter, an air compressor, a pressure gauge, a thermometer and a hygrometer, and the fermentation rack body 1 is placed in In the fermentation room, a multi-layer tray 6 is arranged in the fermentation frame body 1, and a spraying device 10 is arranged above the tray 6, a steam generator, a strain tank, a high-pressure water pump, an air filter, an air compressor, a pressure gauge, a thermometer and The hygrometer is placed outside the fermentation room, the spraying device 10 is connected to the first reversing valve through the connecting pipe 3, and the first reversing valve is respectively connected to the steam generator, strain tank, high-pressure water pump and air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com