Manufacturing method of biological neural synapsis bionic electronic devices and products thereof

A technology of neural synapses and electronic devices, applied in the direction of electrical components, specific application simulation processes, etc., can solve the problems of synaptic device units not realizing ultra-low energy consumption operation, etc., to facilitate large-scale integration, improve microstructure and corresponding Effects of electrical performance, ultra-low power operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

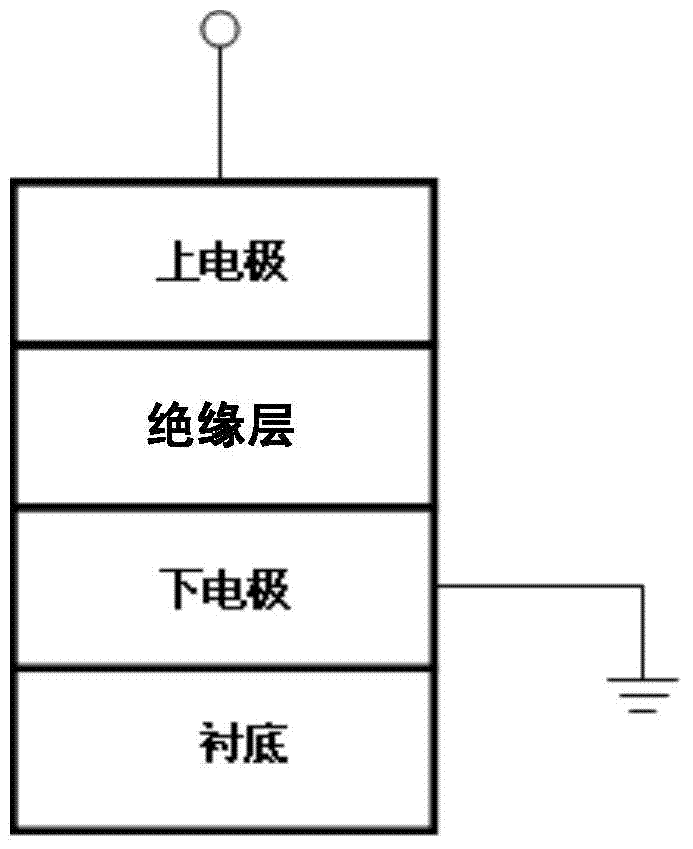

[0036] The preparation method of the neurosynaptic bionic electronic device unit of the present embodiment includes the following steps:

[0037] Step 1. Prepare a 20nm thick titanium thin film and a 150nm thick platinum thin film sequentially on the surface of the substrate as a conductive layer by sputtering.

[0038] In this embodiment, the substrate is a thermally oxidized silicon wafer, and a silicon dioxide isolation dielectric layer is grown on the single crystal silicon to form a thermally oxidized silicon wafer as an insulating substrate. A conductive layer is formed on one side of the silicon dioxide layer of the thermally oxidized silicon wafer.

[0039] Among them, the 20nm thick titanium film is used as a buffer layer, and its main function is to increase the mechanical bonding force between the platinum film and the thermally oxidized silicon wafer.

[0040] Step 2, using magnetron sputtering to prepare a ZnO film with a thickness of 300nm as an insulating film....

Embodiment 2

[0049] Same as Example 1, the difference is that the thickness of the ZnO film prepared in step 2 is 15nm, the amplitude of the first pulse (positive pulse) applied in step 4 is 0.8V, and the second pulse (negative pulse) The amplitude is 0.2V.

[0050] Correspondingly, the difference between the bionic synapse bionic electronic device prepared in this example and Example 1 is that the thickness of the ZnO film in the middle layer is 15 nm, and the pulse voltage used in step 4 is different.

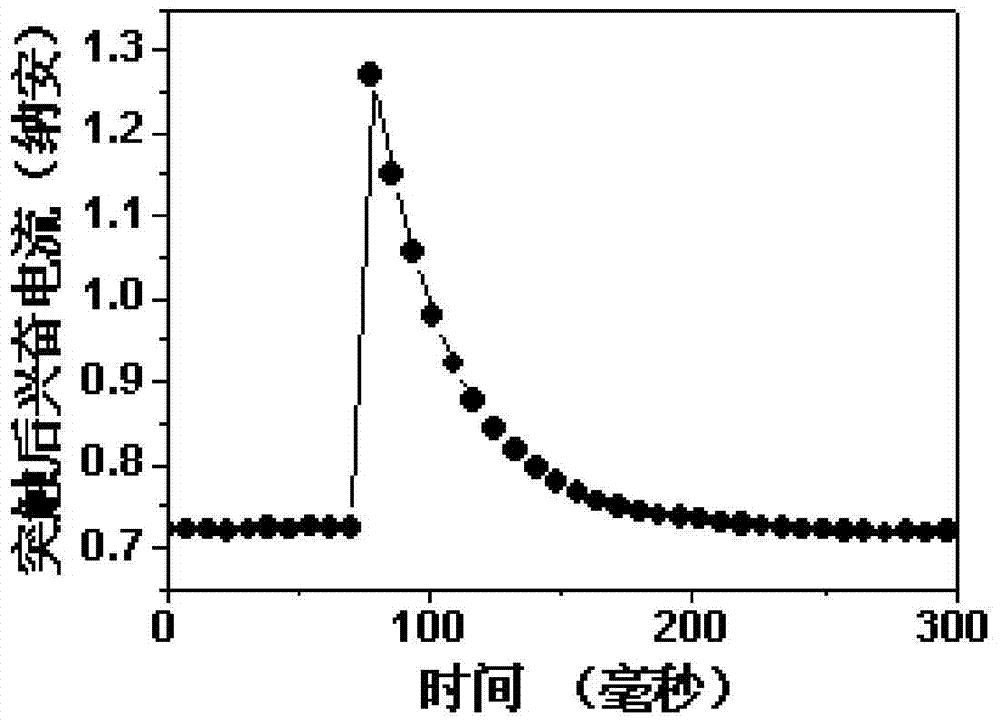

[0051] For the Cu / ZnO / Pt stack structure processed by the two-step voltage method, apply a forward pulse voltage with an amplitude of 5mV and a width of 10ns, and use a voltage of 1mV to read the current value in real time. image 3 This is the relationship between the post-synaptic excitatory current changing with time. It can be seen that under the excitation of a positive pulse voltage with an amplitude of 5mV and a width of 10ns, the device current reaches a peak of 1.3nA, and then d...

Embodiment 3

[0053] Same as Example 1, except that the electrically insulating film prepared in step 2 is amorphous carbon (a-C) with a thickness of 10 nm, the sputtering target is graphite, and the sputtering atmosphere is nitrogen or a mixed gas of nitrogen and argon. The amplitude of the first pulse (positive pulse) applied in step 4 is 3V, and the amplitude of the second pulse (negative pulse) is 0.5V.

[0054] Correspondingly, the difference between the bionic synapse bionic electronic device prepared in this example and Example 1 is that the middle layer is an a-C film with a thickness of 10 nm, and the pulse voltage used in step 4 is different.

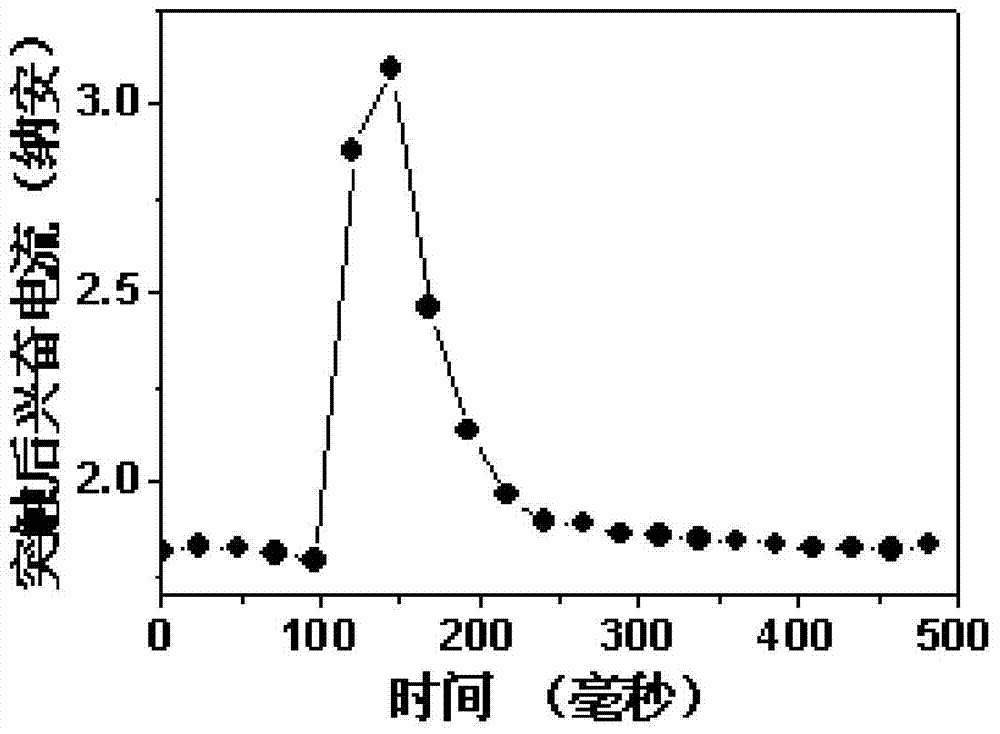

[0055] For the Cu / a-C / Pt stack structure processed by the two-step voltage method, apply a forward pulse voltage with an amplitude of 10mV and a width of 100ns, and use a voltage of 1mV to read the current value in real time. Figure 4 This is the relationship between the post-synaptic excitatory current changing with time. It can be seen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com