Processing method of crispy carrot strips

A processing method and carrot technology, applied in the field of food processing, can solve the problems of insignificant color protection effect, and achieve the effects of suitable sweetness, crisp taste and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

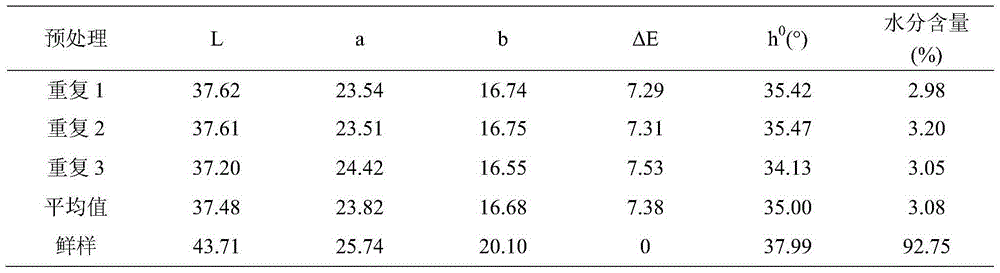

[0033] Embodiment 1, the processing of crisp carrot strip 1

[0034] (1) Cleaning, peeling and cutting of raw materials: wash carrots with water to remove surface dirt. Remove the carrot epidermis with a thickness of 1 mm, then cut the carrot into carrot segments of 4 cm, and then vertically quarter and cut into four pieces to obtain carrot sticks with a thickness of about 0.7 cm;

[0035] (2) Soak the sliced carrot sticks in step (1) in hot water at a temperature of 95°C for 3 minutes, then rinse with cold water at 25°C to cool, drain and set aside;

[0036] (3) Pretreatment: deep-freeze the carrot strips after blanching in step (2), the temperature is -60°C, the time is 4h, and the mass concentration of boiling (100°C) maltose syrup is 40% maltose syrup The solution was precooked for 20 minutes, wherein the mass ratio of the carrot sticks to the maltose syrup solution with a mass concentration of 40% of the maltose syrup was 1:3 to obtain pretreated carrot sticks;

[003...

Embodiment 2

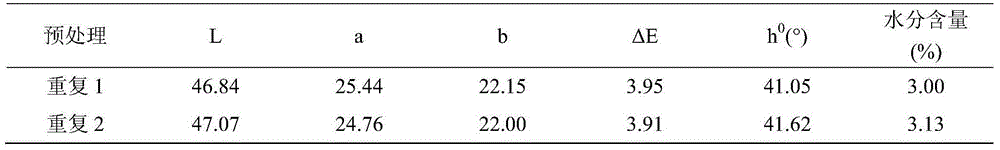

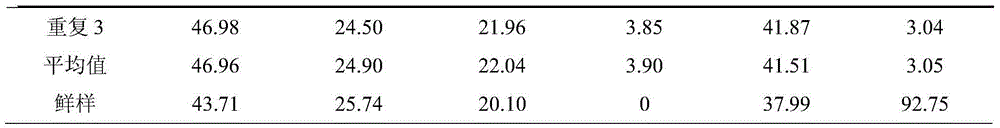

[0039] Embodiment 2, the processing of crisp carrot strip 2

[0040] (1) Cleaning, peeling and cutting of raw materials: wash carrots with water to remove surface dirt. Remove the carrot epidermis with a thickness of 1 mm, then cut the carrot into carrot segments of 4 cm, and then vertically quarter and cut into four pieces to obtain carrot sticks with a thickness of about 0.7 cm;

[0041] (2) Soak the sliced carrot sticks in step (1) in hot water at a temperature of 95°C for 3 minutes, then rinse with cold water at 23°C to cool, drain and set aside;

[0042] (3) Pretreatment: deep-freeze the carrot strips after blanching in step (2), the temperature is -60°C, the time is 4h, and then under the condition of 50°C water bath insulation, the mass concentration of maltose syrup is 40%. Soaking in maltose syrup solution for 2 hours, wherein the mass ratio of the carrot sticks to the maltose syrup solution with a mass concentration of 40% of the maltose syrup is 1:3 to obtain pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com