Gold-palladium alloy/carbon nitride composite nanomaterial and preparing method and application thereof

A technology of composite nanomaterials and gold-palladium alloys, applied in the field of electrocatalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

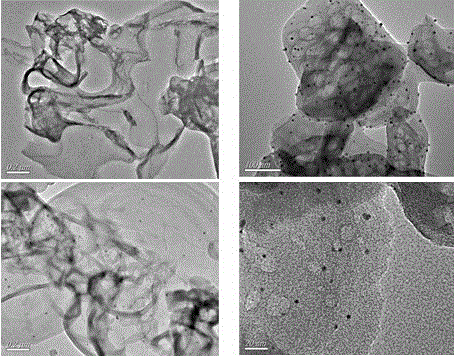

[0020] Embodiment 1 class graphitic nitrogen carbide (g-C 3 N 4 ) preparation

[0021] g-C 3 N 4 The preparation adopts the method of thermal polymerization of urea; weigh 10 g of urea in a semi-closed crucible and place it at 80 o C drying oven for 48 h, then transfer the crucible to the temperature-programmed tube furnace, and the temperature-programmed tube furnace was set at 2.3 o C / min heating rate to 550 o C and keep it warm for 4 h. After cooling down to room temperature naturally, take it out, grind it into powder with a mortar, and use a concentration of 0.01 mol L -1 dilute HNO 3 Wash 3 times to remove residual alkaline species, then wash 3 times with deionized water and absolute ethanol, and finally wash at 80 o C oven dried for 12 h.

Embodiment 21

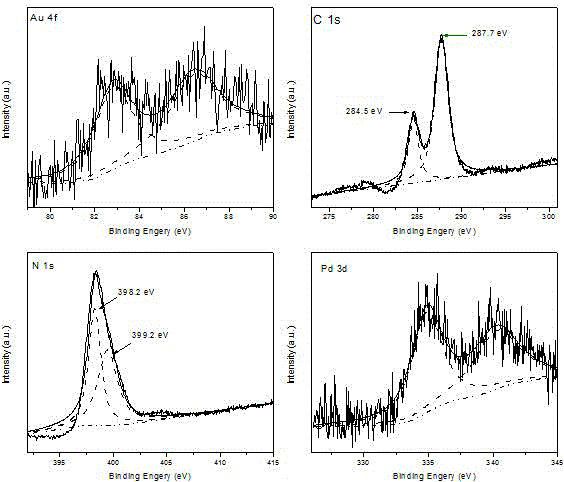

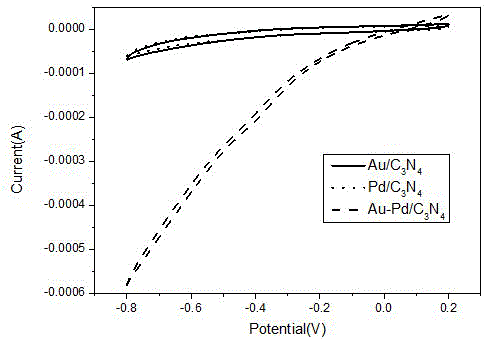

[0022] Example 21%-1% Au-Pd / g-C 3 N 4 Preparation of Composite Nanomaterials

[0023] Weigh 0.1g g-C 3 N 4 Dissolve the powder in 100mL of pure water, then ultrasonically disperse for 0.5 h in an ultrasonic machine with a power of 250W, and then add 0.5 ml of 0.01 mol L -1 HAuCl 4 solution and 0.94 ml 0.01 mol L -1 h 2 PdCl 4solution, stirred magnetically for 0.5 h, and added dropwise 20ml of 0.15 mol L within 1 hour -1 NaBH 4 solution, magnetically stirred for 0.5 h; then cooled to room temperature in an oil bath at 100°C for 24 h, cooled to room temperature after reaction, washed, centrifuged, and dried to obtain Au, Pd and g-C 3 N 4 1%-1% Au-Pd / g-C with a mass ratio of 1% 3 N 4 composite nanomaterials.

Embodiment 3

[0024] Example 3 2% Pd / g-C 3 N 4 Preparation of Composite Nanomaterials

[0025] Weigh 0.1g g-C 3 N 4 The powder was dissolved in 100ml of pure water, then ultrasonicated for 0.5h in an ultrasonic machine with a power of 250W, and then 1.88ml of 0.01 mol L was added -1 h 2 PdCl 4 solution, magnetically stirred for 30 min, after complete mixing, 20ml of 0.15 mol L was added dropwise within 1 hour -1 NaBH 4 solution, after magnetic stirring for 30 min, react in an oil bath at 100°C for 24 h; after the reaction, cool to room temperature, wash, centrifuge, and dry to obtain 2% Pd / g-C 3 N 4 composite nanomaterials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com