Self-reinforced phenolic resin quick-curing precoated sand and preparation method thereof

A technology of phenolic resin and coated sand, which is used in manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of high curing temperature, unfavorable environment, and excessively brittle materials, achieve low curing temperature, improve curing speed, The effect of reducing the curing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

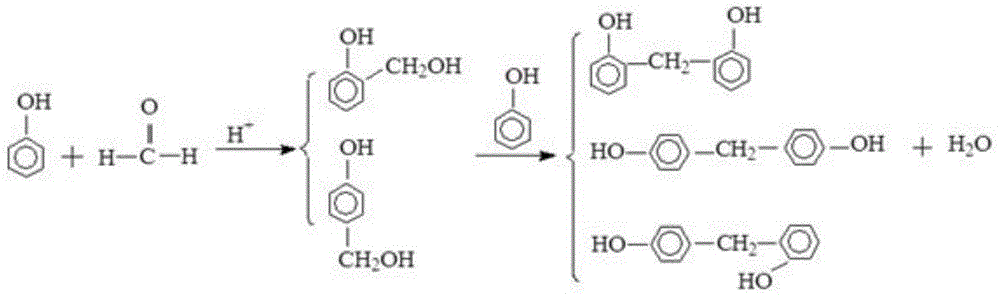

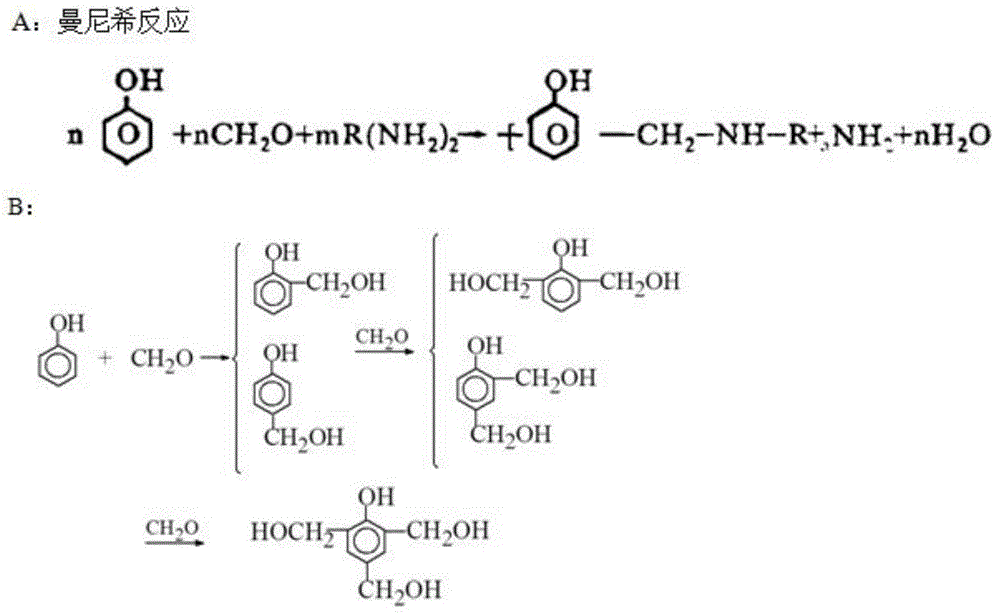

Method used

Image

Examples

Embodiment 1

[0024] The aqueous solution containing 37% formaldehyde and phenol are dropped into the reactor 1 according to mol ratio 1:1.1 and fully mixed; then in the reactor 1, add the oxalic acid that accounts for 3% by weight of phenol as a catalyst, and add the γ- Aminopropyltriethoxysilane was used as a silane coupling agent, and the pH of the solution was controlled to be 2.1 to form a mixed solution; the above mixed solution was heated to 60 °C in a water bath and refluxed for 1 hour; is 2kg / min, and the temperature of the solution is controlled to be 80°C, until the molecular weight distribution index of the solution detected by gel permeation chromatography is D=M(w) / M(n) is 1.5, and the dropwise addition of formaldehyde is stopped; finally, the solution is dehydrated under reduced pressure, And remove the unreacted phenol, control the dehydration temperature to 188 ℃, and then the desired thermoplastic phenolic resin can be obtained.

[0025] Phenol, containing 37% aqueous form...

Embodiment 2

[0028] The aqueous solution containing 37% formaldehyde and phenol are dropped into the reactor 1 according to mol ratio 1:1.1 and fully mixed; then in the reactor 1, add the oxalic acid that accounts for 3% by weight of phenol as a catalyst, and add the γ- Aminopropyltriethoxysilane was used as a silane coupling agent, and the pH of the solution was controlled to be 2.1. The obtained solution was heated to 60 °C in a water bath and refluxed for 1 hour to form a mixed solution; then formaldehyde was added dropwise to the mixed solution at a uniform rate, and the rate of addition was is 2kg / min, the temperature of the control solution is 85°C, until the molecular weight distribution index of the solution detected by gel permeation chromatography is D=M(w) / M(n) is 1.6, the dropwise addition of formaldehyde is stopped; finally, the solution is dehydrated under reduced pressure, And remove the unreacted phenol, control the dehydration temperature to 188 ℃, and then the desired ther...

Embodiment 3

[0032] The aqueous solution containing 37% formaldehyde and phenol are dropped into the reactor 1 according to mol ratio 1:1.2 and fully mixed; Then in the reactor 1, add the oxalic acid that accounts for 4% by weight of phenol as a catalyst, and add the γ- Aminopropyltriethoxysilane was used as a silane coupling agent, and the pH of the solution was controlled to be 2.1. The obtained solution was heated to 65°C in a water bath and refluxed for 1.5 hours to form a mixed solution; then formaldehyde was added dropwise to the mixed solution at a uniform rate, and the rate of addition was is 2kg / min, the control solution temperature is 85 ℃, until the molecular weight distribution index of the solution detected by gel permeation chromatography is D=M(w) / M(n) is 1.7, stop dripping formaldehyde; finally the solution is decompressed and dehydrated, And remove the unreacted phenol, control the dehydration temperature to 188 ℃, and then the desired thermoplastic phenolic resin can be ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com