Automatic panel taking, transferring and machining numerical control equipment

A technology of numerical control equipment and panel, which is applied in the direction of metal processing equipment, metal processing, metal processing machinery parts, etc., can solve the problem of increasing the labor burden of operators, poor positioning and clamping effect of glass panels or metal panels, and reducing the automation degree of CNC machine tools and other problems, to achieve the effect of improving automatic positioning, reducing the probability of waste products, improving processing efficiency and processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

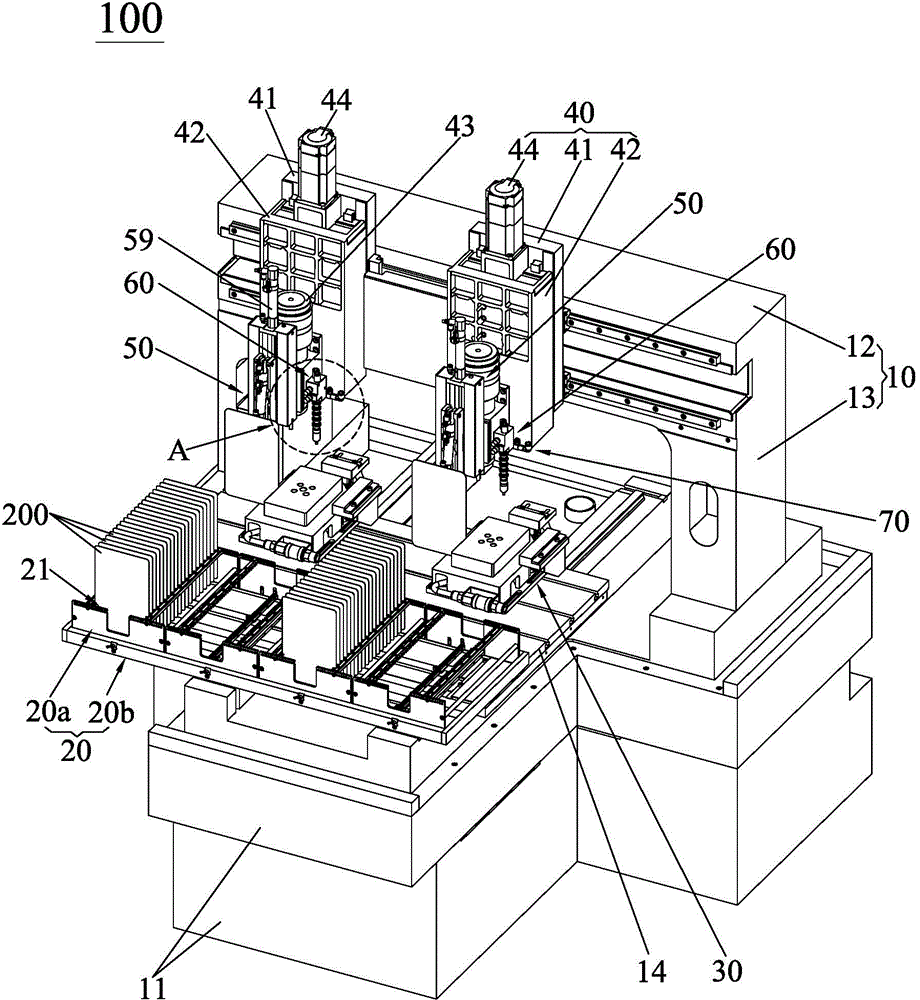

[0026] In order to describe the technical content and structural features of the present invention in detail, further descriptions will be made below in conjunction with the embodiments and accompanying drawings.

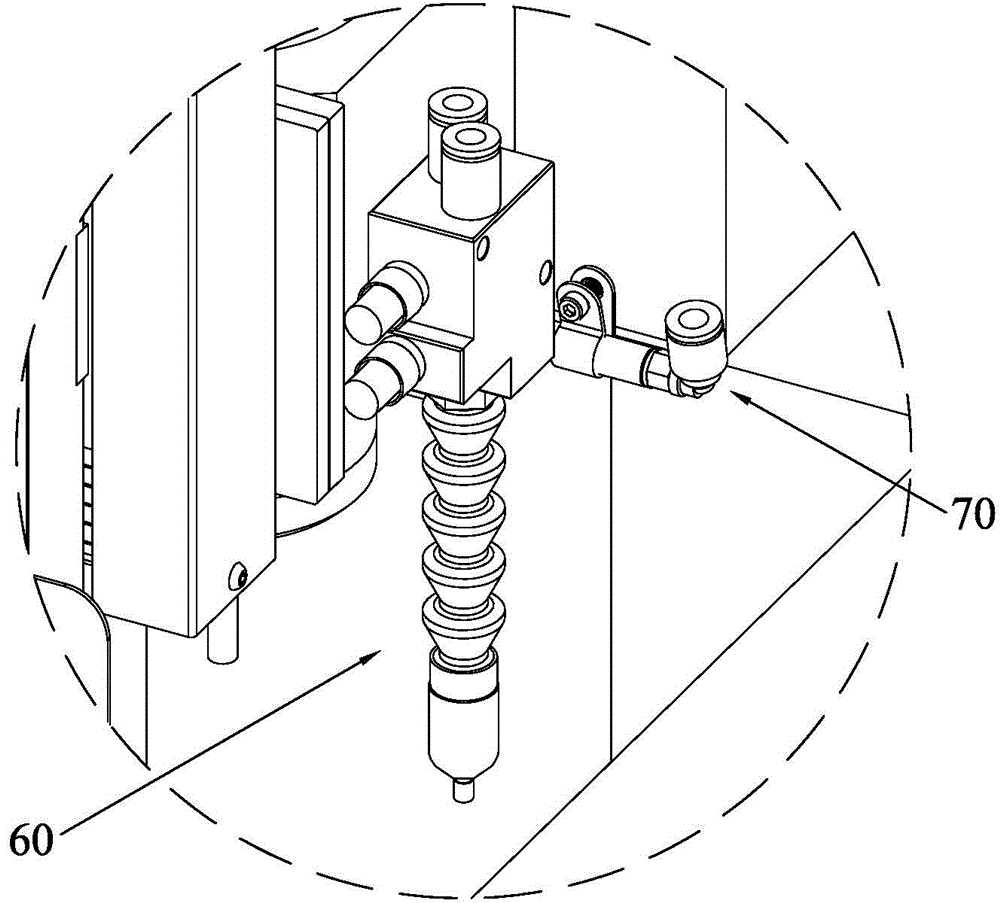

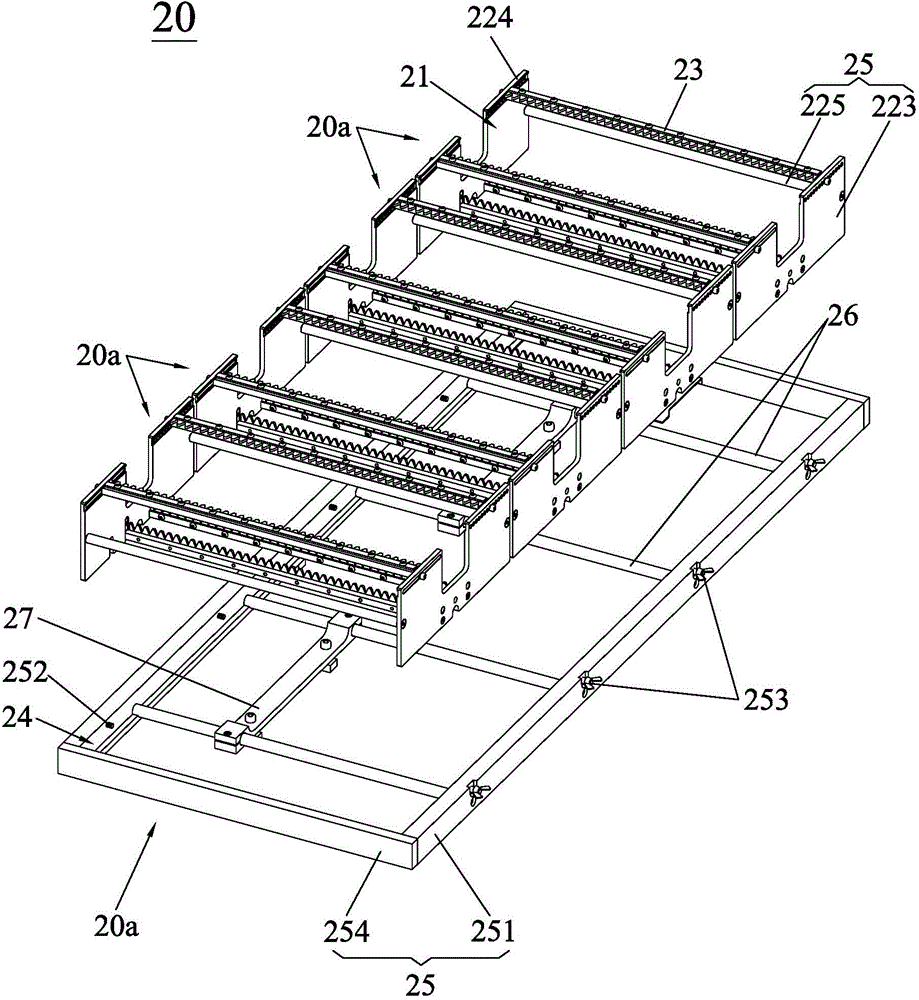

[0027] see figure 1 and figure 2 , the numerical control equipment 100 for automatic panel refueling and processing of the present invention integrates refueling and processing of the panel 200 to improve the processing effect and quality of the panel 200, and the numerical control equipment 100 for automatic panel refilling and processing of the present invention includes a machine Frame 10, material box device 20, positioning fixture 30, machine head 40 and refueling manipulator 50; specifically, in order to prevent fouling, so the panel automatic refueling processing numerical control equipment 100 of the present invention can also include an atomization moisturizing device 60; in order to prevent scratching of the panel 200, the numerical control equipment 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com