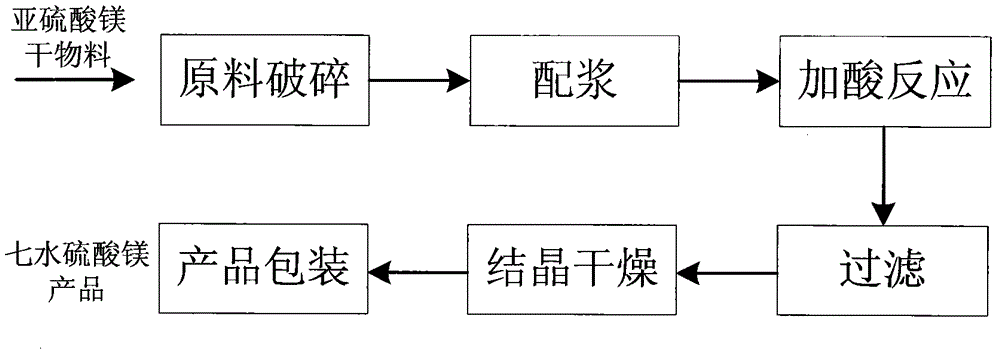

Crystallization and drying integrated method for heptahydrate magnesium sulfate preparation

A technology of magnesium sulfate heptahydrate and magnesium sulfate, applied in magnesium sulfate and other directions, can solve the problems of high energy consumption of evaporation and crystallization, large consumption of water resources, easy scaling of heat exchange surface, etc., and achieves small footprint and low investment. , without the effect of mother liquor circulation and drying system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] The magnesium sulfate solution with a concentration of 42w% and a temperature of 75°C is pumped into the crystallization drying tower through the liquid phase pipe. The atomization medium gas temperature in the device is 25°C, the atomization pressure is 4.5kg, the wind speed inside the tower is 15m / s, the air temperature at the tower inlet is 15°C, and the negative pressure inside the tower is -100pa. Finally, the magnesium sulfate heptahydrate product with a purity of 98% is obtained, and the product quality meets the requirements of GB / T 26568-2011, wherein the magnesium sulfate heptahydrate crystal particle size collected at the bottom is between 0.5 and 3mm, and the crystal particle size collected by the cyclone separator is Below 1mm, the product collected at the bottom of the tower accounts for more than 80% of the total output.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com