Method for improving settling separation performance of bauxite slurry

A technology of sedimentation and separation, bauxite, applied in chemical instruments and methods, aluminum compounds, alumina/aluminum hydroxide, etc. Problems such as rising, to achieve the effect of obvious rise of underflow solids, improved sedimentation and separation effect, and increased sedimentation velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

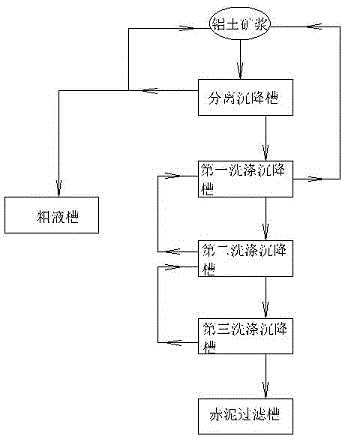

[0010] Such as figure 1 As shown, the method for improving the sedimentation and separation performance of bauxite slurry in the present invention is to carry out sedimentation and separation of the bauxite slurry leached at high pressure in the separation settling tank, and the overflow clear liquid of the separation settling tank is divided into two paths, and one path is used to pump its Lead to the crude liquid tank of the leaf filter system, all the way to dilute and dilute the bauxite slurry dissolved by high pressure, that is, set a dilution tank at the entrance of the separation and settling tank, and the bauxite slurry dissolved by high pressure enters the separation and settling tank. Mix and dilute the overflow clear liquid in the dilute tank, and then enter the separation and settling tank. The bottom flow of the separation and settling ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com