Refuse landfill leachate treatment method

A technology for landfill and landfill leachate, which is applied in the field of domestic waste treatment, can solve the problems of no outlet operation cost for concentrated liquid, high power consumption of biological treatment unit, and high operation cost of leachate, and achieves good effluent quality, C/ The effect of improving N ratio and avoiding excessive free ammonia concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

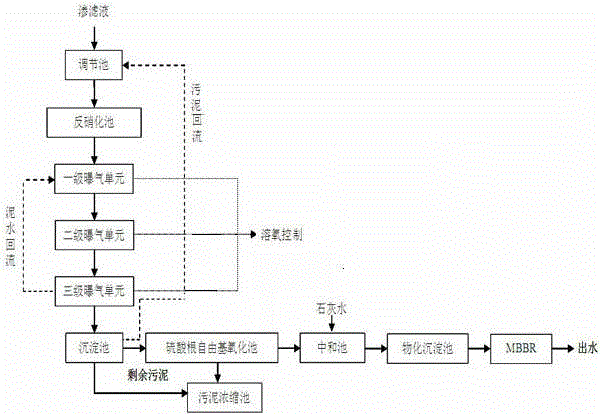

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] refer to figure 1 , Taking the actual leachate of a domestic waste landfill in Hangzhou as an example, the wastewater treatment scale is 10 L / d. The average COD of the leachate cr is 6000 mg / L, average NH 4 + -N is 1650 mg / L, the average total nitrogen is 1750 mg / L, the average total phosphorus is 5 mg / L, the C / N is 3.4, and the B / C is about 0.45.

[0023] The processing method of the landfill leachate of the present invention comprises the following steps:

[0024] 1) The raw leachate is pumped into the adjustment tank and the backflow sludge is mixed and settled into the denitrification tank. The hydraulic retention time of the adjustment tank is 1 d, and the return rate is 4-6 times of the influent. The hydraulic retention time is 15 h;

[0025] 2) The micro-oxygen aeration tank is equipped with three-stage aeration units, and the dissolved oxygen in ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com