Cement based grout mortar formula

A cement-based, mortar technology, applied in the field of mortar compositions containing cold phosphate binders, can solve problems such as unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

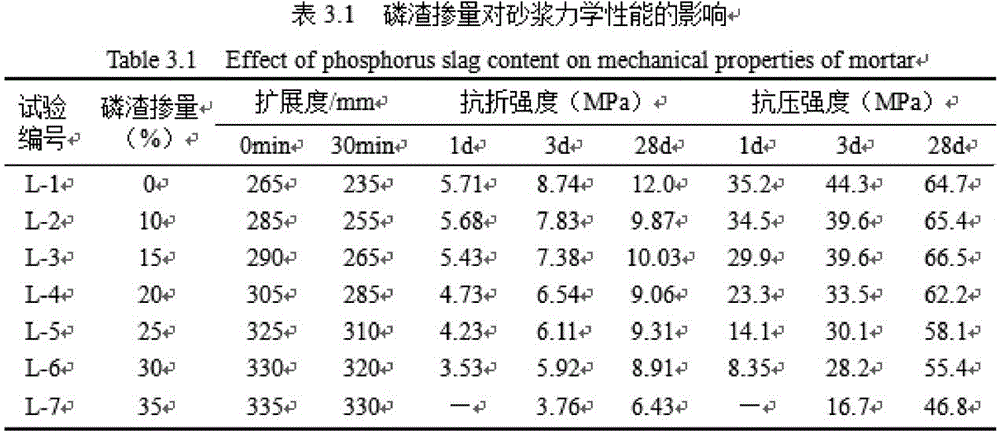

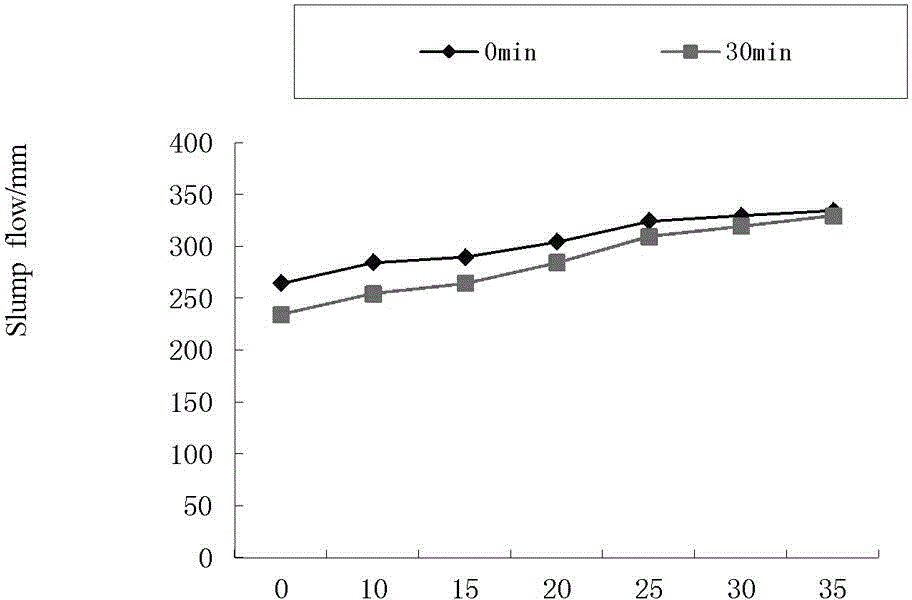

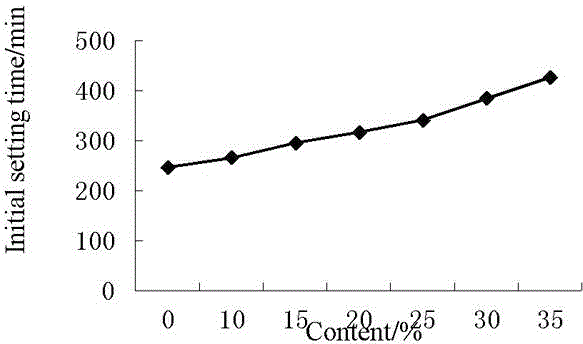

[0030] The formula of a kind of cement-based grouting mortar of the present invention comprises gel material, additive, water and sand, and the ratio of water and gel material is water-cement ratio is 0.26~0.28, and the ratio of gel material and sand is cement-sand ratio is 1 / 1~1 / 1.6. The gel material is composed of ordinary Portland cement and phosphorus slag, and their mass ratios in the gel material are as follows: Portland cement: 70-80 parts, phosphorus slag: 20-30 parts.

[0031] Additives include expansion agent, water reducer, defoamer, early strength agent and thickener, and their respective mass ratios in the gel material are as follows: expansion agent: 6~8 parts, water reducer: 1 part polycarboxylate Acid water reducer or sulfamate water reducer, defoamer: 0.2~0.6 parts of silicone defoamer, early strength agent: 0.04~0.05 parts of triethanolamine, thickener: 0.025~0.05 parts Hydroxypropyl methylcellulose ether with a viscosity of 100,000 mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com