Wet-type water-retaining property dustfall agent

A water-retaining, dust-reducing agent technology, applied in dust prevention, fire prevention, mining equipment, etc., can solve the problems of dust re-rising, poor dust removal effect, secondary pollution, etc., to prevent re-rising, suppress dust, and effectively The effect of settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh respectively according to the following quality standards: 0.02g of starch grafted acrylate, 0.5g of lauryl amidopropyl betaine, 0.01g of cetyltrimethylammonium bromide, 0.2g of sodium lauryl sulfate , 0.3g of sodium dodecylbenzene sulfonate, 0.1g of sodium dodecyl sulfonate, 0.4g of sodium oleamide ethanesulfonate, 0.02g of dodecyl dimethyl betaine, 0.2 g of coconut oil diethanolamide, 0.1 g of sodium isooctyl sulfate. Add the above formula raw materials into 98.15kg of clean water, and mix thoroughly to prepare a 100kg wet-type water-retaining dust suppressant. The wet-type water-retaining dust-reducing agent is applied to spray dust removal, and has uniform texture and good stability.

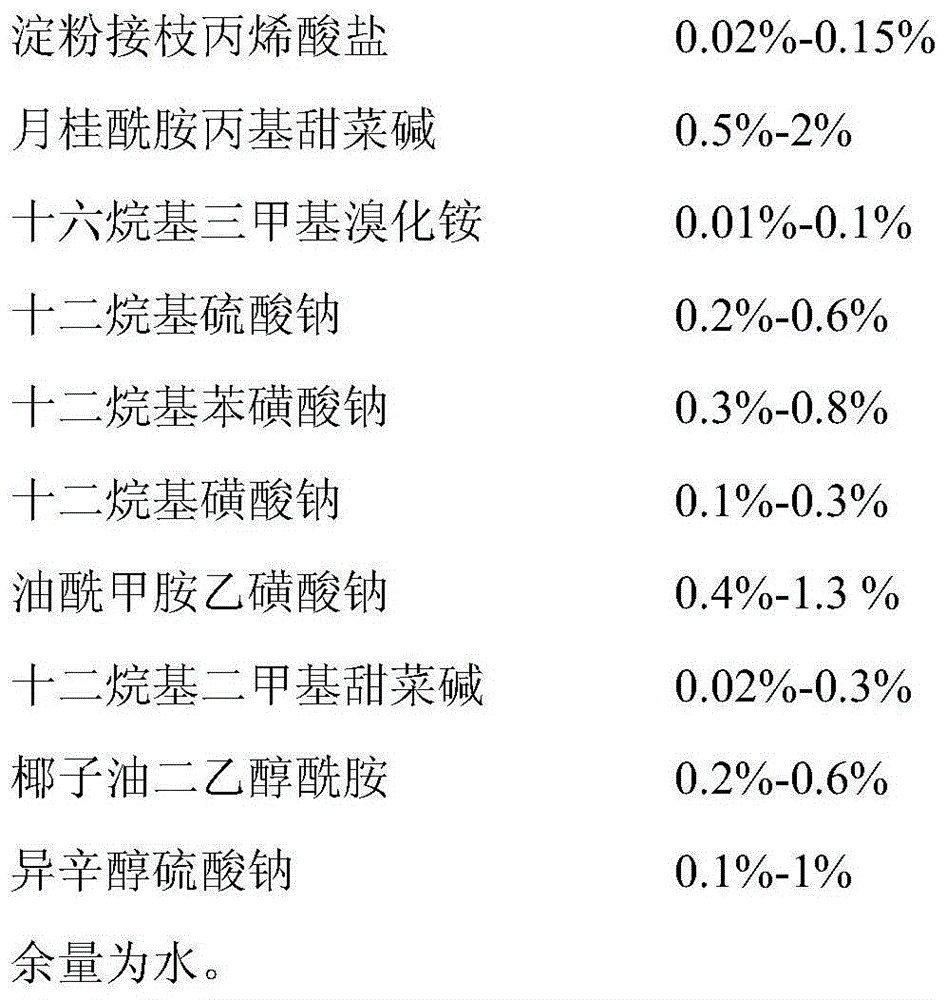

[0029] Among them, in this formula, the percentages of various raw materials are: 0.02% starch grafted acrylate, 0.5% lauryl amidopropyl betaine, 0.01% cetyltrimethylammonium bromide, 0.2% % sodium dodecyl sulfate, 0.3% sodium dodecylbenzenesulfonate, 0.1% sodium dodecylsulfon...

Embodiment 2

[0031] Weigh respectively according to the following quality standards: 0.05g of starch grafted acrylate, 0.8g of lauryl amidopropyl betaine, 0.05g of cetyltrimethylammonium bromide, 0.3g of sodium lauryl sulfate , 0.4g sodium dodecylbenzenesulfonate, 0.15g sodium dodecylsulfonate, 0.5g sodium oleamide ethanesulfonate, 0.05g dodecyldimethyl betaine, 0.3g of coconut oil diethanolamide, 0.2g of sodium isooctyl sulfate. Add the above formula raw materials into 97.20kg of clean water, and mix thoroughly to prepare 100kg of wet water-retaining dust suppressant. The wet-type water-retaining dust-reducing agent is applied to spray dust removal, and has uniform texture and good stability.

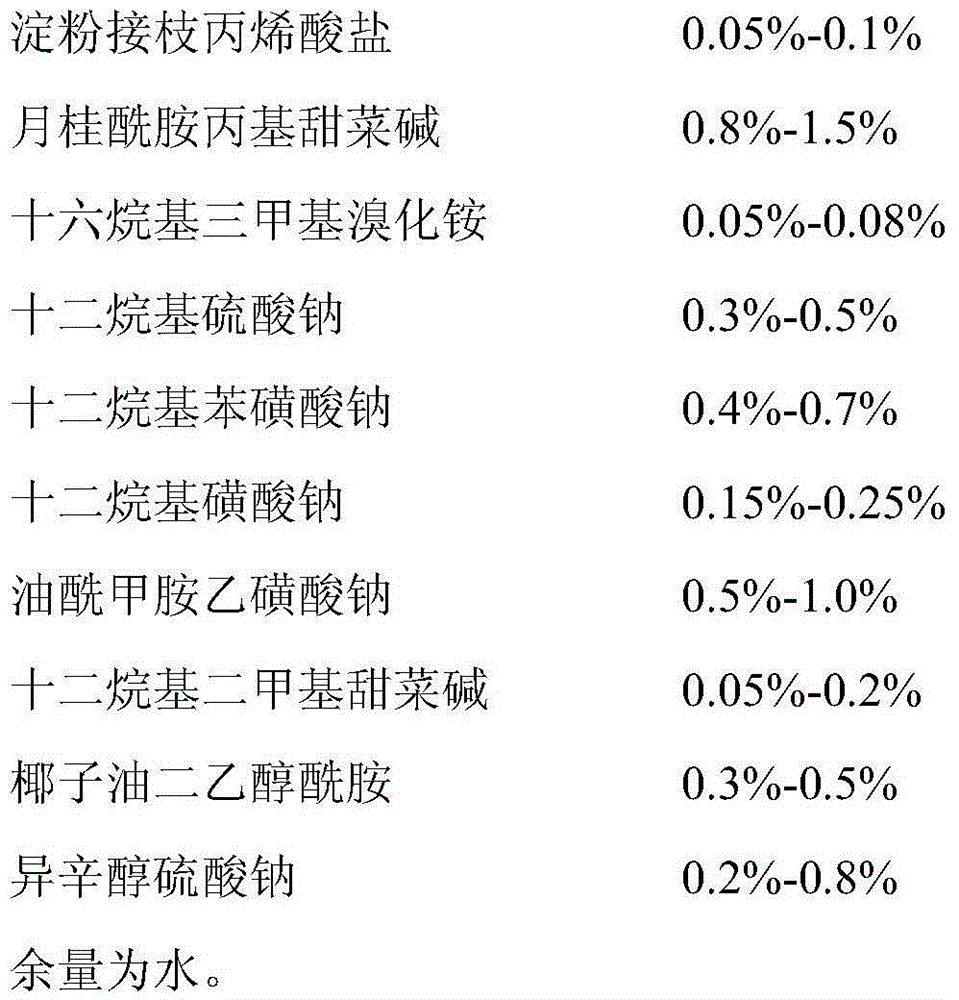

[0032] Among them, in this formula, the percentages of various raw materials are: 0.05% starch grafted acrylate, 0.8% lauryl amidopropyl betaine, 0.05% cetyl trimethyl ammonium bromide, 0.3 % sodium lauryl sulfate, 0.4% sodium dodecylbenzenesulfonate, 0.15% sodium dodecylsulfonate, 0.5% sodium ol...

Embodiment 3

[0034] Weigh respectively according to the following quality standards: 0.06g of starch grafted acrylate, 1.0g of lauryl amidopropyl betaine, 0.06g of cetyltrimethylammonium bromide, 0.35g of sodium lauryl sulfate , 0.45g of sodium dodecylbenzene sulfonate, 0.18g of sodium dodecyl sulfonate, 0.6g of sodium oleamide ethanesulfonate, 0.1g of dodecyl dimethyl betaine, 0.35g of coconut oil diethanolamide, 0.4g of sodium isooctyl sulfate. Add the above formula raw materials into 96.45kg of clean water, and mix thoroughly to prepare 100kg of wet-type water-retaining dust suppressant. The wet-type water-retaining dust-reducing agent is applied to spray dust removal, and has uniform texture and good stability.

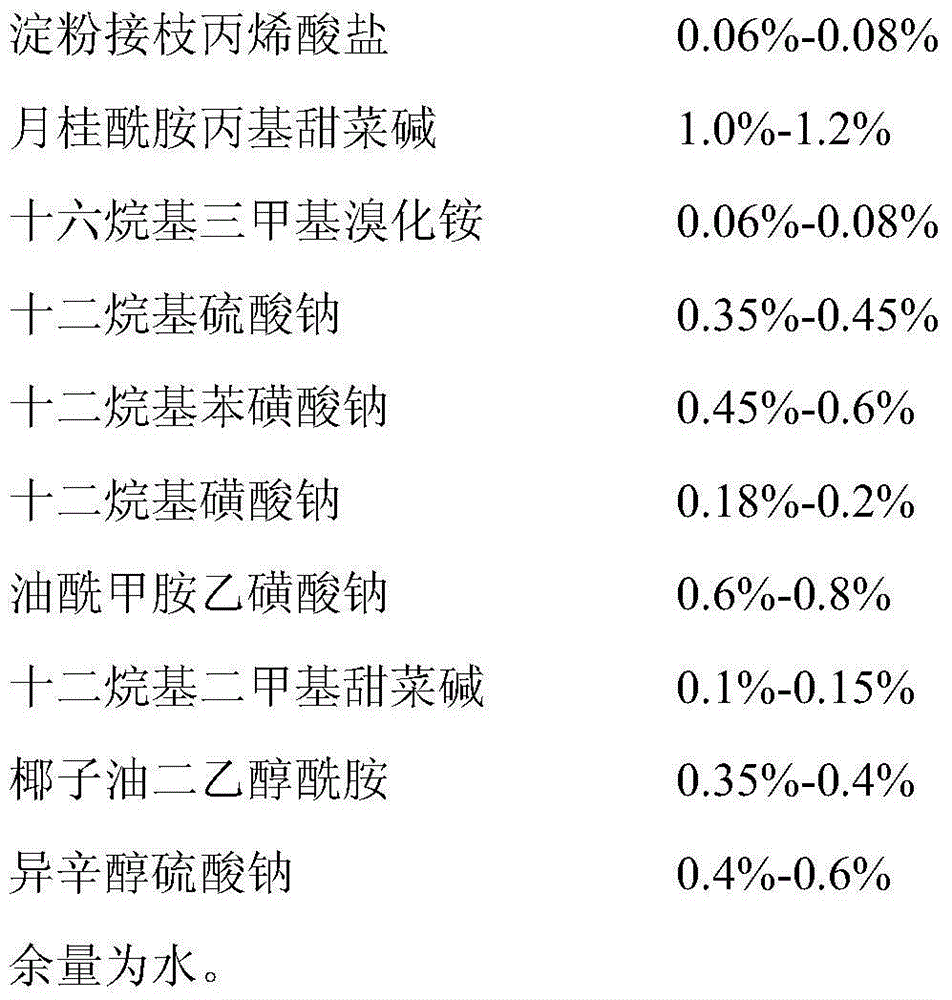

[0035]Among them, in this formula, the percentages of various raw materials are: 0.06% starch grafted acrylate, 1.0% lauryl amidopropyl betaine, 0.06% cetyl trimethyl ammonium bromide, 0.35 % sodium lauryl sulfate, 0.45% sodium dodecylbenzenesulfonate, 0.18% sodium dodecylsu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com