Preparation method of polyphenol oxidase immobilizing carrier

A technology of polyphenol oxidase and immobilized carrier, which is applied in the direction of fixing on or in the inorganic carrier, fixing on/in the organic carrier, etc., which can solve the separation difficulties and unfavorable immobilization of chitosan-gold nanoparticles Eliminate the problems of repeated use of enzymes, and achieve the effects of high immobilization efficiency, high enzyme activity, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

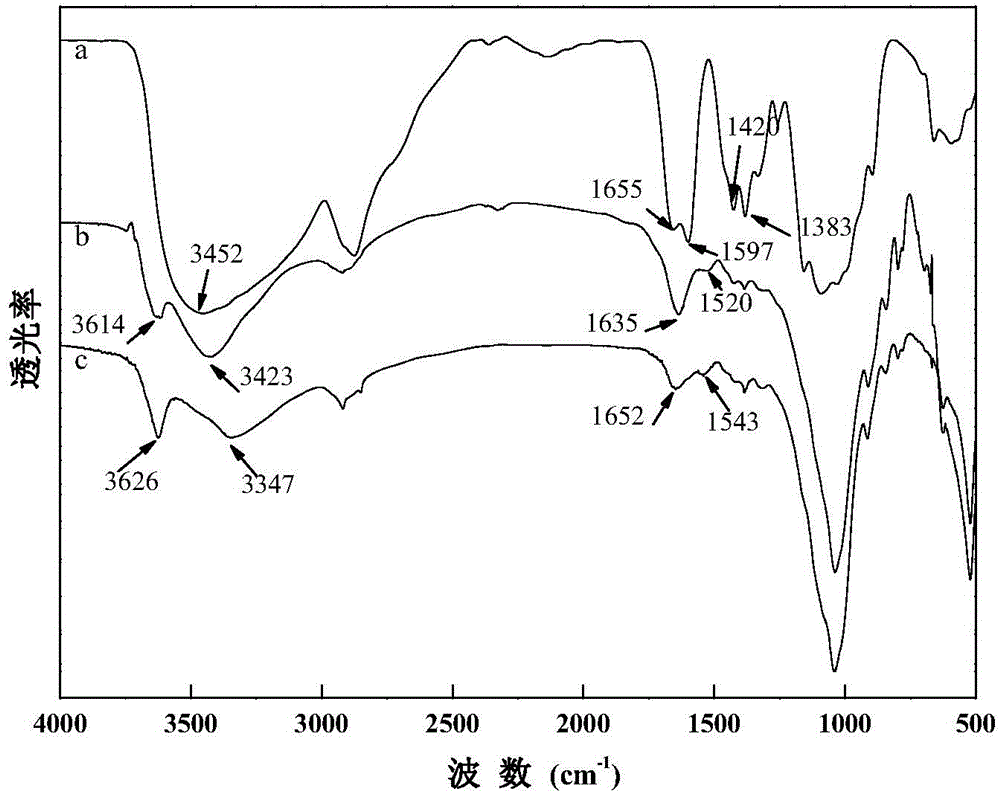

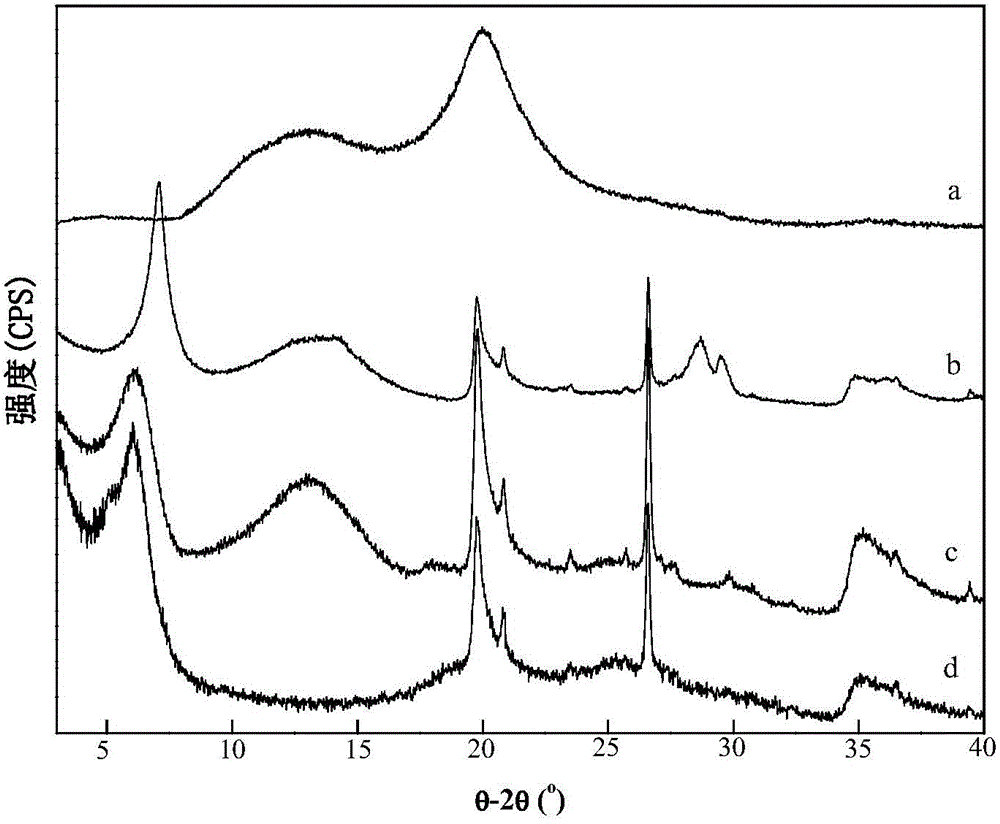

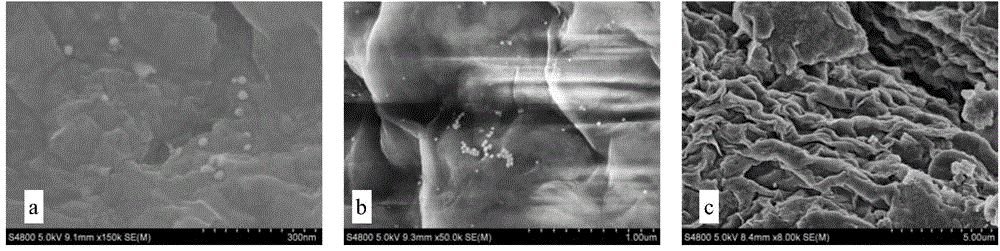

[0024] Add 4.0 g of Na-based montmorillonite into 100 mL of distilled water and stir at room temperature for 2 h to make it fully swell. Dissolve 3.3 g of chitosan in 250 mL of 1% (v / v) acetic acid solution, and adjust the pH value to 4.9 with 20% (w / v) NaOH solution after fully dissolving. The chitosan solution was slowly added to the montmorillonite suspension, heated to 60°C, and stirred for 6 h. After the reaction, centrifuge, wash and dry to obtain the chitosan / montmorillonite intercalation complex.

[0025] Dissolve chloroauric acid in distilled water to prepare a chloroauric acid solution with a concentration of 0.01 mM, and adjust the pH to 9.0 with 1 M NaOH solution. The chitosan / montmorillonite intercalation complex was added to the above chloroauric acid solution, so that the mass ratio of chloroauric acid to chitosan / montmorillonite intercalation complex was 0.15% (w / w). Stir fully at 80°C for 1 h under constant temperature and magnetic force. After the reaction,...

Embodiment 2

[0032] Dissolve chloroauric acid in distilled water to prepare a chloroauric acid solution with a concentration of 0.05 mM, and adjust the pH to 3.0 with 1 M HCl solution. The chitosan / montmorillonite intercalation complex was added to the above chloroauric acid solution, so that the mass ratio of chloroauric acid to chitosan / montmorillonite intercalation complex was 0.50% (w / w). Stir at 60°C for 2 h under constant temperature and magnetic force. After the reaction, centrifuge and wash the product with distilled water until the pH of the supernatant is neutral to obtain the chitosan-nanogold / montmorillonite intercalation complex.

[0033] Add chitosan-nanogold / montmorillonite intercalation complex to the polyphenol oxidase buffer solution of pH 7.0, so that the mass ratio of polyphenol oxidase to chitosan-nanogold / montmorillonite intercalation complex carrier is 80 mg / g. Shake and adsorb at 25°C for 5 h, remove the enzyme solution by filtration, wash the immobilized enzyme wi...

Embodiment 3

[0035] Dissolve chloroauric acid in distilled water to prepare a chloroauric acid solution with a concentration of 0.10 mM, and adjust the pH to 6.0 with 1 M NaOH solution. The chitosan / montmorillonite intercalation complex was added to the above chloroauric acid solution, so that the mass ratio of chloroauric acid to chitosan / montmorillonite intercalation complex was 1.00% (w / w). Stir at 60°C for 1.5 h under constant temperature and magnetic force. After the reaction, centrifuge and wash the product with distilled water until the pH of the supernatant is neutral to obtain the chitosan-nanogold / montmorillonite intercalation complex.

[0036] Add chitosan-nanogold / montmorillonite intercalation complex to the polyphenol oxidase buffer solution of pH 6.0, so that the mass ratio of polyphenol oxidase to chitosan-nanogold / montmorillonite intercalation complex carrier is 60 mg / g. Shake and adsorb at 30°C for 4 h, remove the enzyme solution by filtration, wash the immobilized enzyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com