Method for preparing immobilized cell carrier from tamarind seed gum and sodium alginate complex gel

A technology of immobilizing cells and sodium alginate is applied in the material field of immobilized cell carriers, which can solve the problems of reducing the efficiency of immobilization, the loss of microbial activity, and the loss of microorganisms, so as to reduce the loss of activity, reduce the loss of microorganisms, and reduce the loss of microorganisms. The effect of fast forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

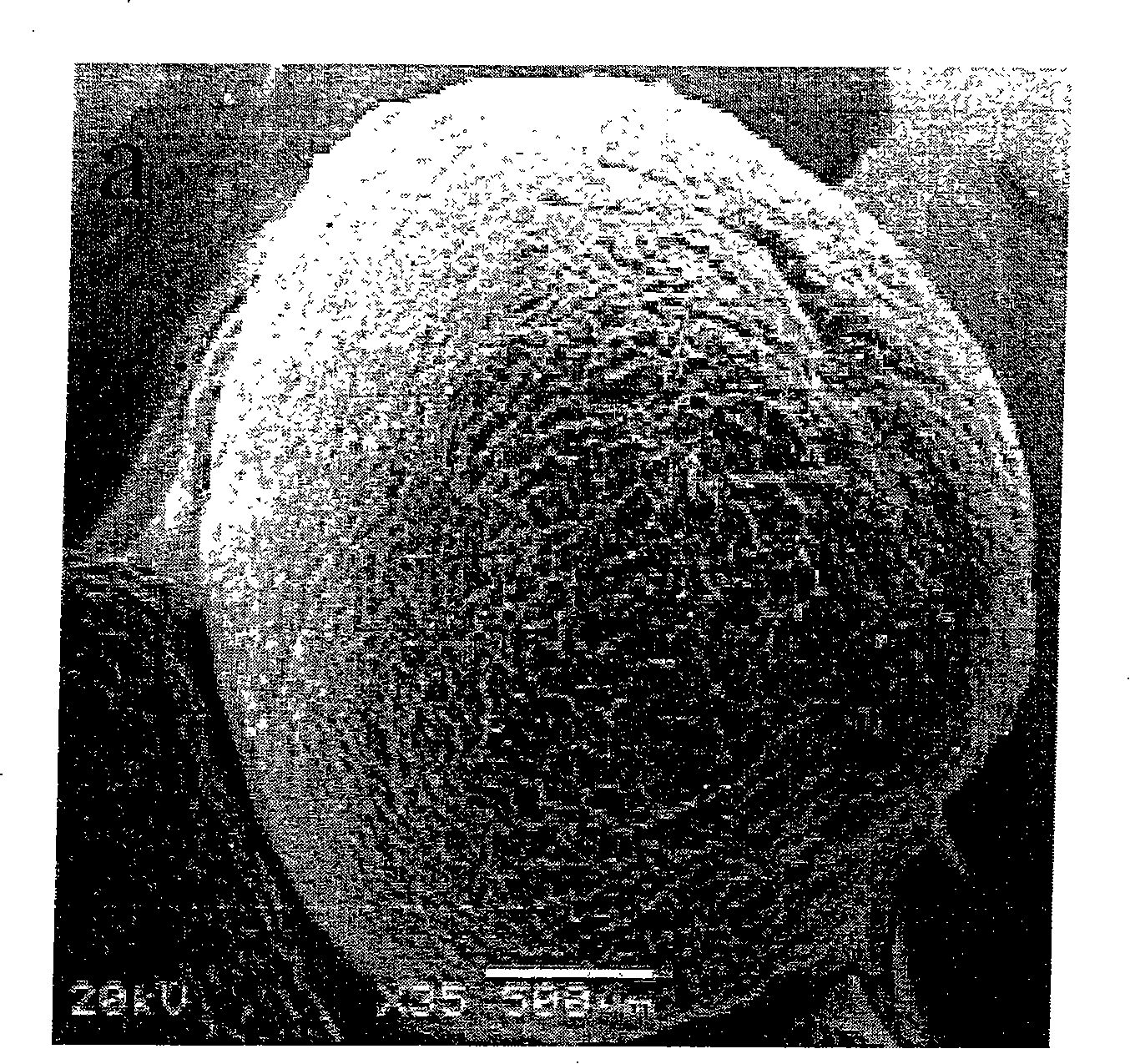

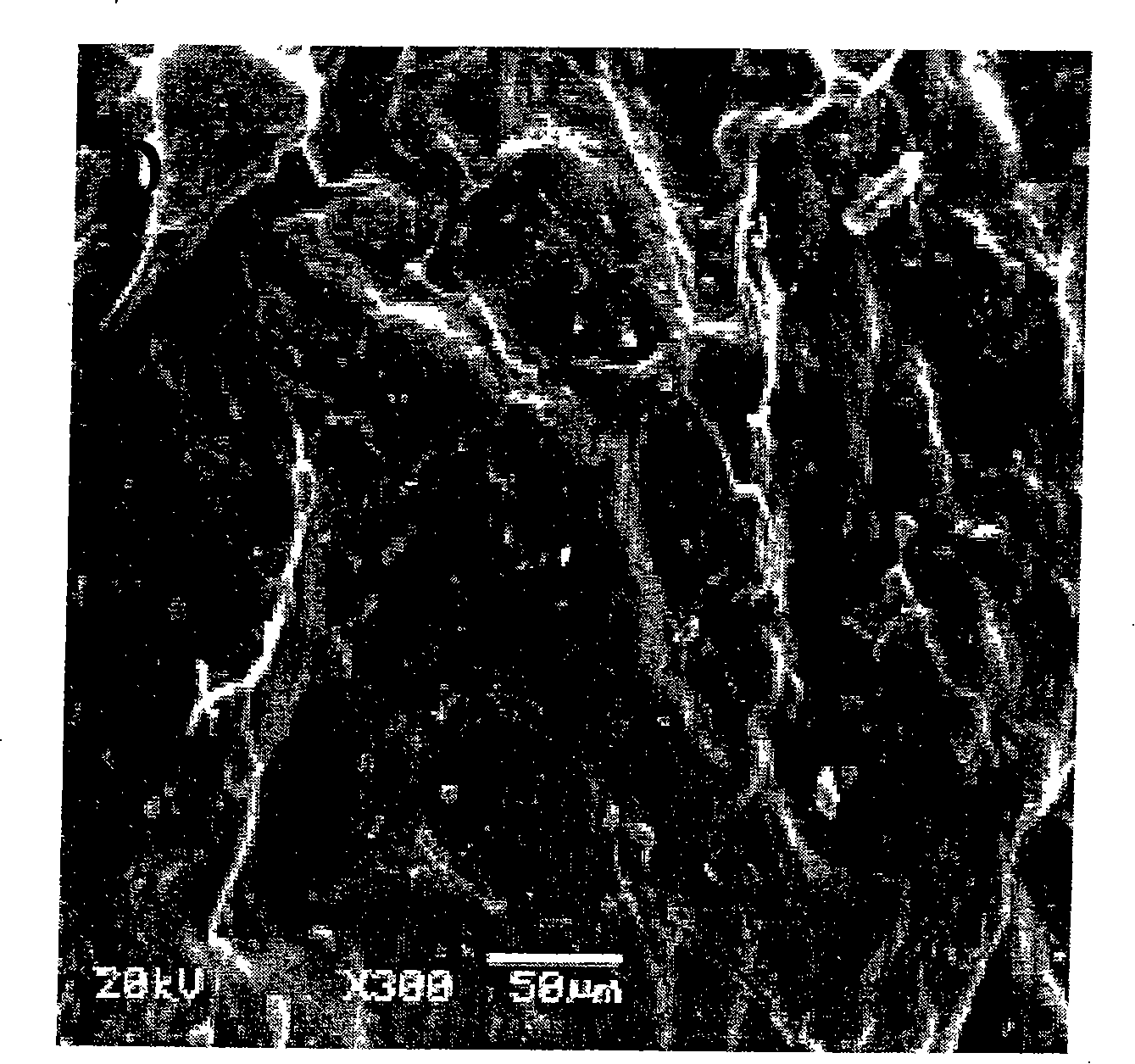

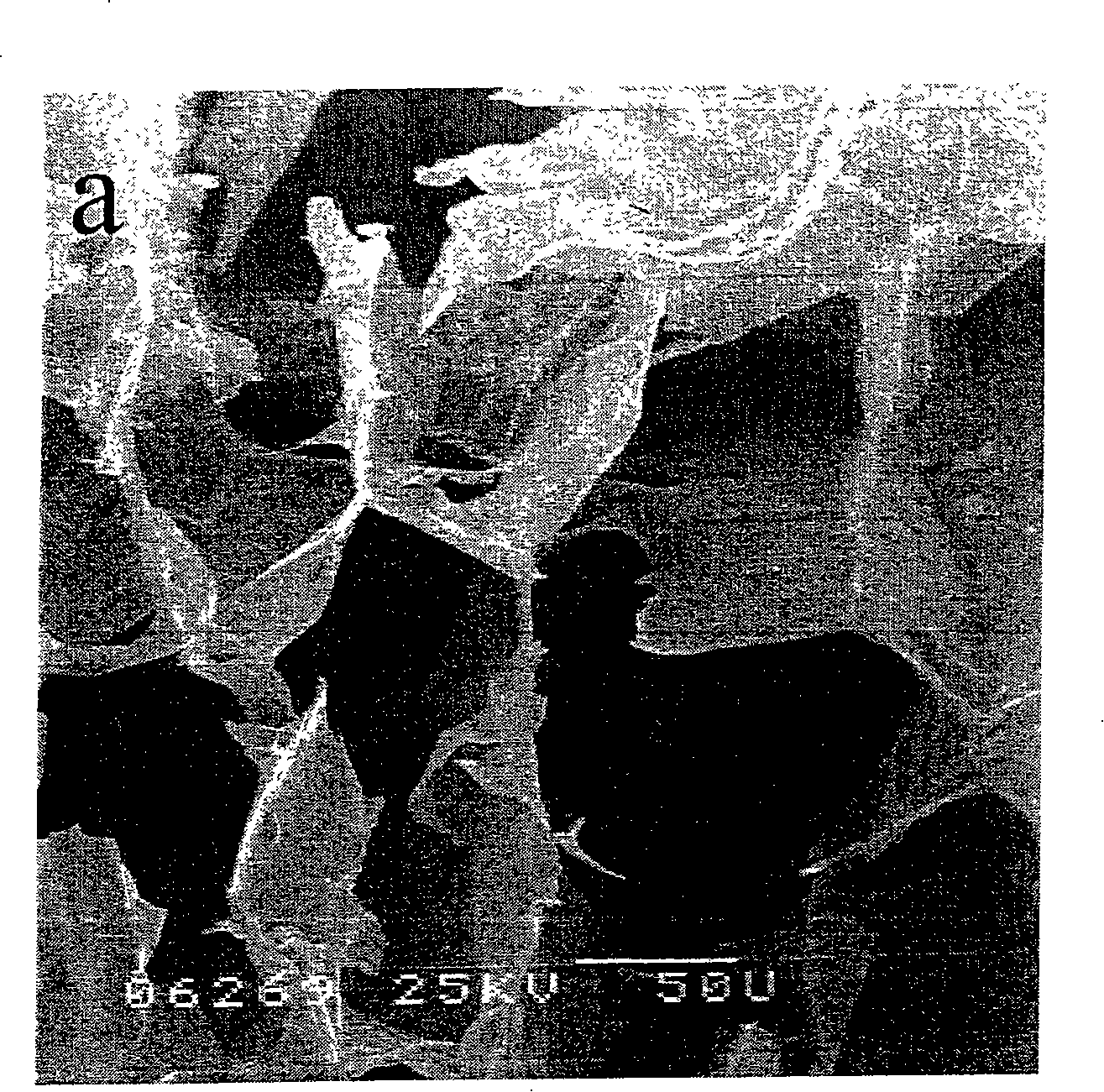

[0025] 1) Under the condition that the temperature is 85°C and the rotating speed is 500 rpm, a composite aqueous solution of tamarind gum and sodium alginate with a concentration of 2.4% by weight is prepared, and the mass ratio of tamarind gum and sodium alginate is 5: 1. Stir at constant temperature for 25 minutes to obtain a compound solution of tamarind gum and sodium alginate, then cool to room temperature and set aside;

[0026] 2) At a temperature of 3°C and a speed of 120 rpm, use a syringe with a No. 7 needle to drop the compound solution obtained in step 1) into a calcium chloride solution with a concentration of 2.5% by weight, and compound The volume ratio of the solution and the calcium chloride solution was 1:10, and the constant temperature curing reaction was carried out for 2 hours, and a composite gel of tamarind gum and sodium alginate was initially formed to immobilize the cell carrier.

[0027] 3) At room temperature, remove the calcium chloride solution ...

Embodiment 2

[0030] 1) Under the condition that the temperature is 95°C and the rotating speed is 600 rpm, a composite aqueous solution of tamarind gum and sodium alginate with a concentration of 3.0% by weight is prepared, and the mass ratio of tamarind gum and sodium alginate is 4: 1. Stir at constant temperature for 35 minutes to obtain a composite solution of tamarind gum and sodium alginate, then cool to room temperature and set aside;

[0031] 2) At a temperature of 5°C and a speed of 150 rpm, use a syringe with a No. 7 needle to drop the compound solution obtained in step 1) into a calcium chloride solution with a concentration of 3.5% by weight, and compound The volume ratio of the solution and the calcium chloride solution is 1.5:10, and the curing reaction is carried out at a constant temperature for 2 hours, and a composite gel of tamarind gum and sodium alginate is initially formed to immobilize the cell carrier;

[0032] 3) At room temperature, remove the calcium chloride solu...

Embodiment 3

[0035] 1) Under the condition that the temperature is 90°C and the rotating speed is 550 rpm, a composite aqueous solution of tamarind gum and sodium alginate with a concentration of 2.7% by weight is prepared, and the mass ratio of tamarind gum and sodium alginate is 4.5: 1. Stir at constant temperature for 30 minutes to obtain a compound solution of tamarind gum and sodium alginate, then cool to room temperature and set aside;

[0036] 2) at a temperature of 4°C and at a speed of 135 rev / min, drop the composite solution of bentonite into the calcium chloride solution of 3.0% by weight with a syringe with a No. 7 needle, the composite solution and chloride The volume ratio of the calcium solution is 1.25:10, and the constant temperature curing reaction is carried out for 1.5 hours, and the composite gel of tamarind gum and sodium alginate is initially formed to immobilize the cell carrier;

[0037] 3) At room temperature, remove the calcium chloride solution by filtration, wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com