Micro-fluidic chip for detecting fluoride in water body and preparation method thereof

A microfluidic chip and detection chip technology, applied in chemical instruments and methods, laboratory containers, color/spectral property measurement, etc., can solve the problem of no substantial breakthrough in fluoride, and achieve good application prospects , the effect of reducing consumption, reducing processing and detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

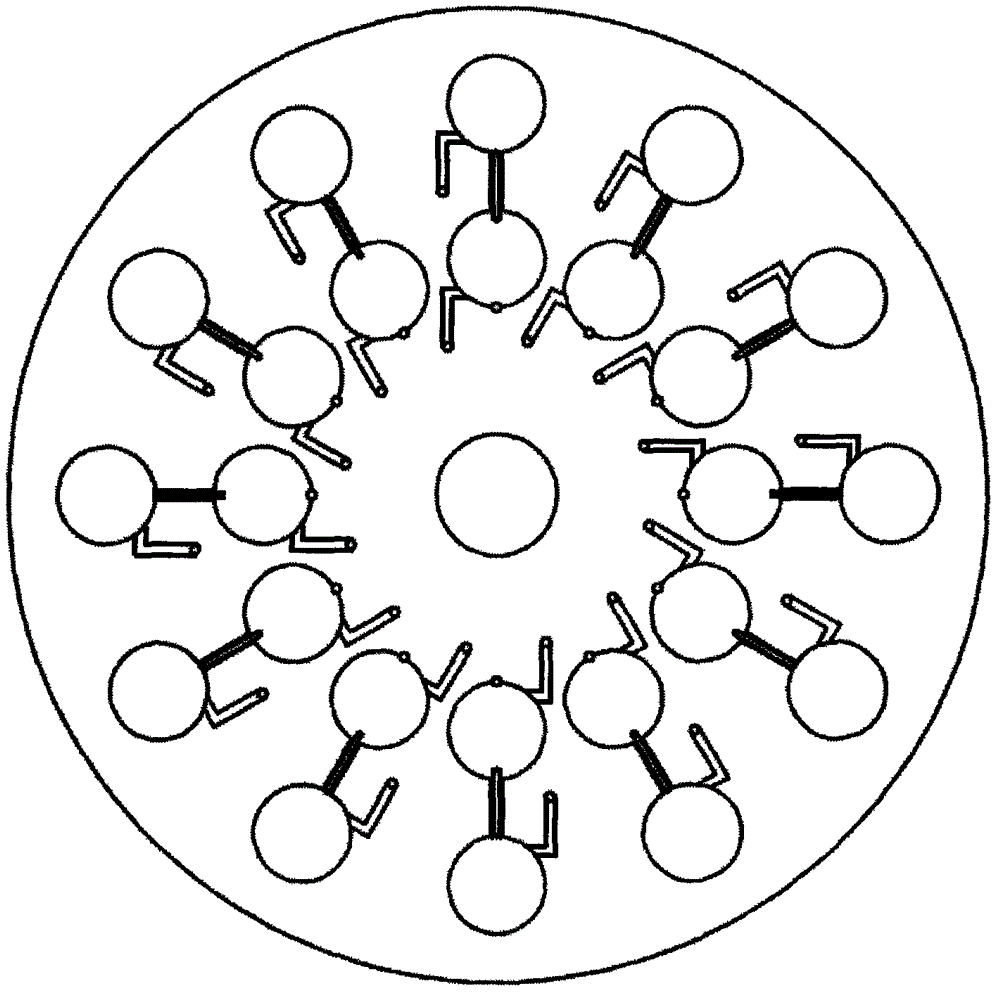

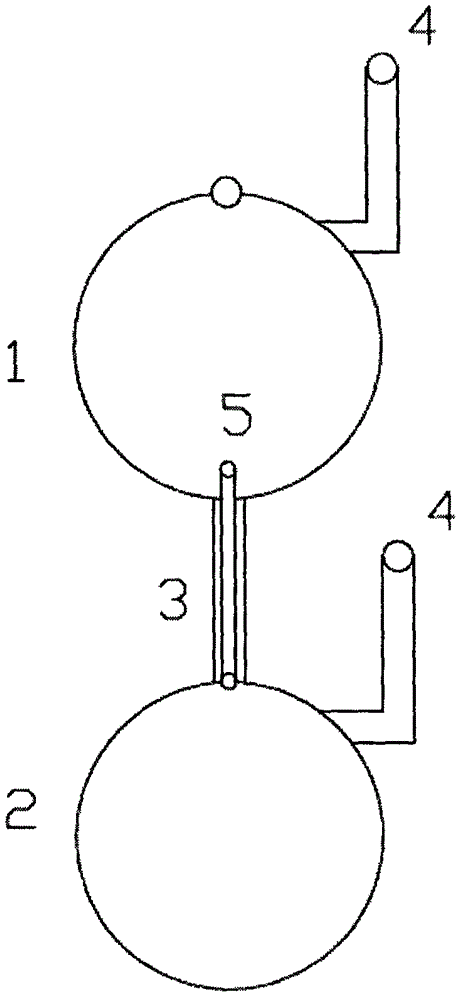

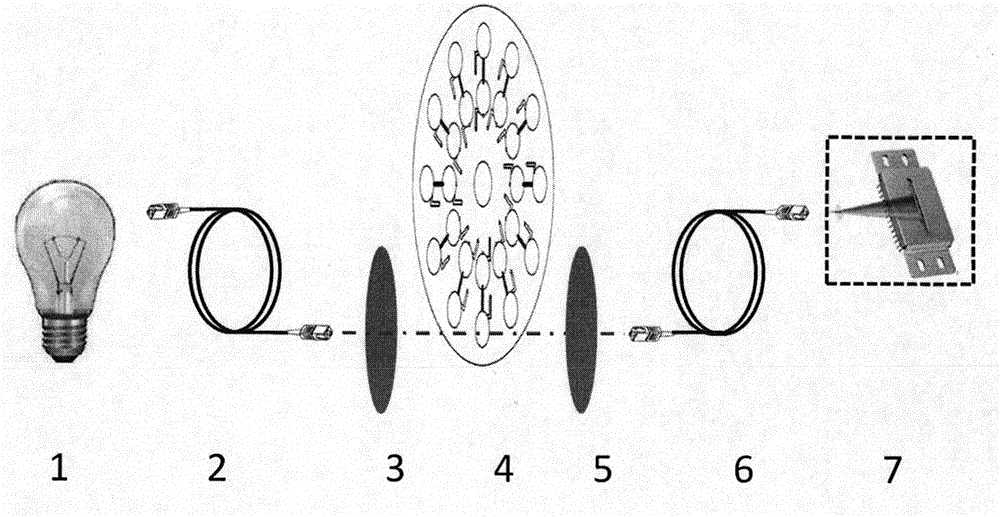

[0030] Design and draw the microstructure and microchannel graphics of the microfluidic chip with computer-aided design software. Microstructures and microchannels were prepared on polymethyl methacrylate (PMMA) substrates by numerical control CNC micromachining system. Finally, the substrates were cleaned with tap water and distilled water respectively, and residual fingerprints, oil stains and other stains on the surface of the substrates were wiped with ethanol. Place 5ml of the sample to be tested in the sample cell, align, bond, press and seal the substrate with micropatterns, blank substrate and double-layer adhesive film to make a centrifugal microfluidic detection chip for detecting fluoride . Fix the microfluidic chip on the integrated platform of centrifuge rotation and detection, add fluorine reagent, 1 mL of acetate and lanthanum nitrate sodium solution to the sample injection hole, mix at a speed of 300 rpm, and react for 10 minutes. Increase the rotation speed t...

Embodiment 2

[0032] Design and draw the microstructure and microchannel graphics of the microfluidic chip with computer-aided design software. Microstructures and microchannels were prepared on polycarbonate (PC) substrates by a numerically controlled laser micromachining system. Finally, the substrates were cleaned with tap water and distilled water, and residual fingerprints, oil stains and other stains on the surface of the substrates were wiped with ethanol. Place 5ml of the sample to be tested in the sample cell, align, bond, press and seal the substrate with micropatterns, blank substrate and double-layer adhesive film to make a centrifugal microfluidic detection chip for detecting fluoride . Fix the microfluidic chip on the integrated platform of centrifuge rotation and detection, add fluorine reagent, 1 mL of acetate and lanthanum nitrate sodium solution to the sample injection hole, mix at a speed of 300 rpm, and react for 10 minutes. Increase the rotation speed to 1000 rpm, move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com