Device and method for directly growing atom-dimension two-dimensional semiconductor heterojunction

A two-dimensional semiconductor and heterojunction technology, applied in the fields of mechanical manufacturing and material science and engineering, can solve the problems of device consistency, difficulty in ensuring repeatability, affecting material device performance, and cumbersome transfer process, so as to shorten the time for material growth , increase the preparation time, and ensure the effect of successful growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

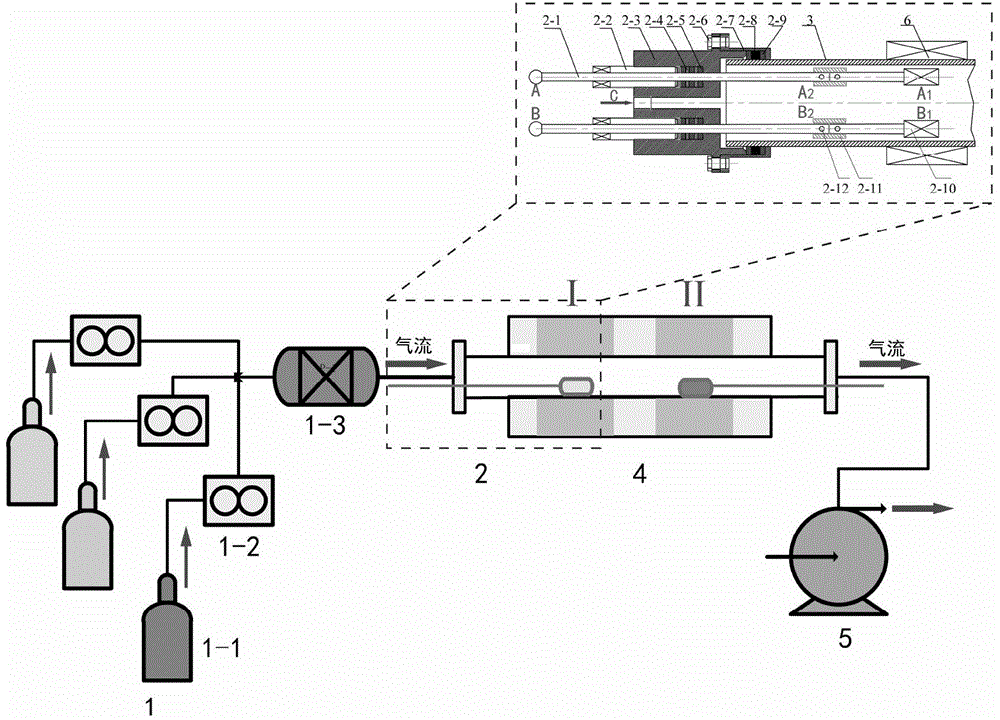

[0031] Specific implementation mode one: as figure 1 As shown, this embodiment provides a device for directly growing an atomic-scale two-dimensional semiconductor heterojunction, which mainly includes five parts: an atmosphere adjustment device 1, a fast switching device 2, a quartz tube 3, a heating device 4, and a vacuum adjustment device 5. Among them, the fast switching device 2 is a key component to ensure the successful preparation of an atomic-scale two-dimensional semiconductor heterojunction.

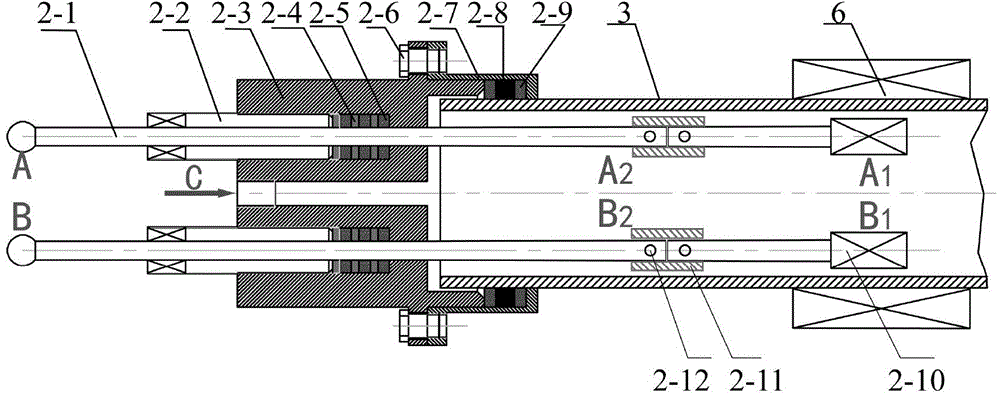

[0032] Such as figure 2 As shown, the quick switching device 2 includes a precursor switching rod 2-1 located at the left end of the quartz tube, a substrate switching rod located at the right end of the quartz tube (the structure is exactly the same as 2-1), a sealing screw 2-2, and a rear end cover 2- 3. Screws 2-6, front end cover 2-7, first sleeve 2-4, second sleeve 2-8, first high temperature resistant O-ring 2-5, second high temperature resistant O-ring 2-9, quartz Co...

specific Embodiment approach 2

[0055]Specific Embodiment 2: Taking two precursor switching rods A, B and one substrate switching rod as examples to illustrate the growth process of the heterojunction of two materials. First, place the reaction precursor and the substrate in the reaction chamber. Typically, the precursor is placed on a quartz member connected to the precursor switching rod, and the substrate is placed on the quartz member connected to the substrate switching rod. In some cases, there are more than one kind of precursors used to grow a substance, and it is necessary to place some substances next to the quartz member on the right end of the quartz tube where the substrate is placed. It reacts with the precursors brought by the carrier gas and forms the desired substance on the substrate. substance. For example, the reaction of using sulfur powder and molybdenum trioxide powder to grow molybdenum disulfide on a silicon substrate. The sulfur powder is placed on the quartz member of the switchin...

specific Embodiment approach 3

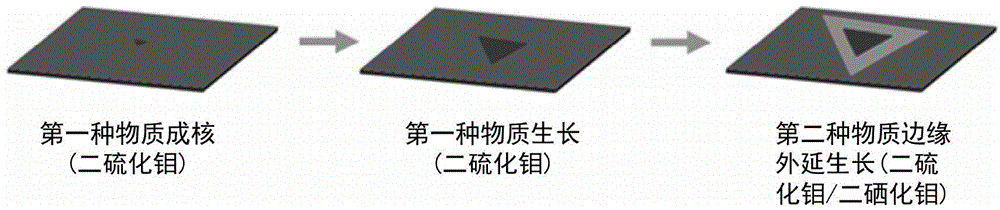

[0058] Embodiment 3: Taking the growth of a molybdenum disulfide / molybdenum diselenide heterojunction as an example, a specific implementation method for directly growing an atomic-scale two-dimensional semiconductor heterojunction is described.

[0059] 1. Using molybdenum trioxide as molybdenum source, elemental sulfur powder and elemental selenium powder as precursors, grow molybdenum disulfide / molybdenum diselenide heterojunction on the substrate.

[0060] 2. Molybdenum trioxide, elemental sulfur powder and selenium powder are commercial products with a purity of 99.9-99.999%, without purification or other treatment before use. The substrate can be a silicon wafer with a silicon dioxide layer, a quartz wafer, a mica wafer, hexagonal boron nitride, etc., and the thickness of the oxide layer of the silicon wafer with a silicon dioxide layer can be 50-500 nm. The purity of molybdenum trioxide is 98-99.99%.

[0061] 3. Place molybdenum trioxide as the molybdenum source on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com