Thin film transistor, manufacturing method of thin film transistor, array substrate and display device

A technology of thin film transistors and manufacturing methods, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve problems such as complex manufacturing processes and increased manufacturing costs, and achieve the goal of reducing quantity, reducing defect state density, and improving stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

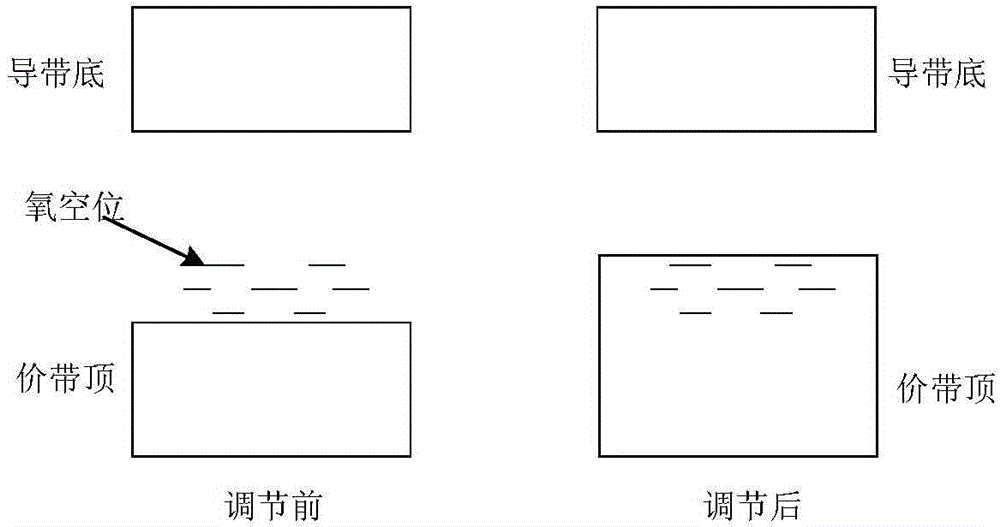

[0032] As a specific embodiment of the present invention, the oxide includes zinc oxide, and the dopant ions include N 3- or S 2- , the molar ratio of the dopant ions to the total amount of oxygen ions in the oxide is between 5% and 80%, which can be regarded as: 5%≤N 3- / (N 3- +O 2- )≤80%, or 5%≤S 2- / (S 2- +O 2- )≤80%. The band gap of zinc oxide is 3.32eV, and the band gaps of zinc nitride and zinc sulfide are both 1.1eV. When the dopant ions include N 3- , the active layer (i.e. doped with N 3-The band gap of the zinc oxide layer) is smaller than the band gap of zinc oxide, and the top of the valence band moves up, thereby reducing the oxygen vacancies Vo; similarly, when the dopant ions include S 2- , the active layer (i.e. doped with S 2- The band gap of the zinc oxide layer) will also be smaller than that of zinc oxide, and the top of the valence band will move up, thereby reducing the oxygen vacancies Vo.

[0033] The thin film transistor includes but is not l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com