Printed circuit board solder mask manufacturing method

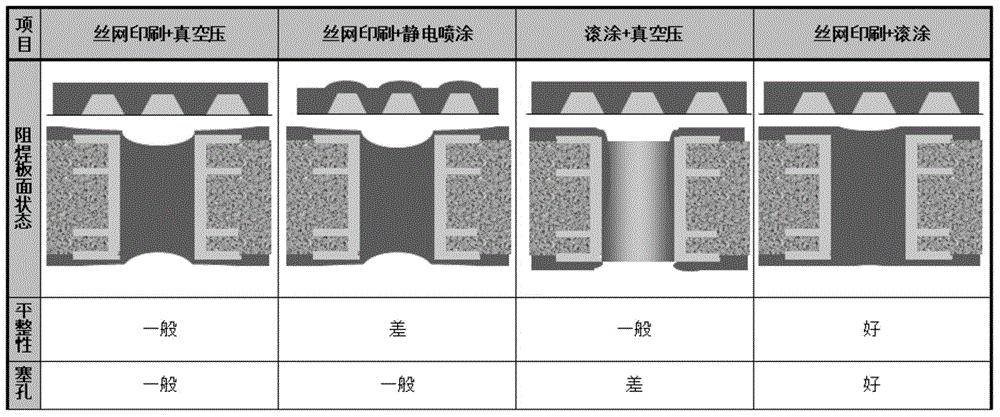

A technology for printed circuit boards and manufacturing methods, which is applied in the fields of printed circuit manufacturing, printed circuits, and secondary processing of printed circuits, and can solve problems such as insufficient flatness of solder resist, inconsistent glue flow speed, and wafer cracks, and achieve improved Improve the flatness of the solder mask surface, reduce the production cost, and reduce the effect of solder mask depression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

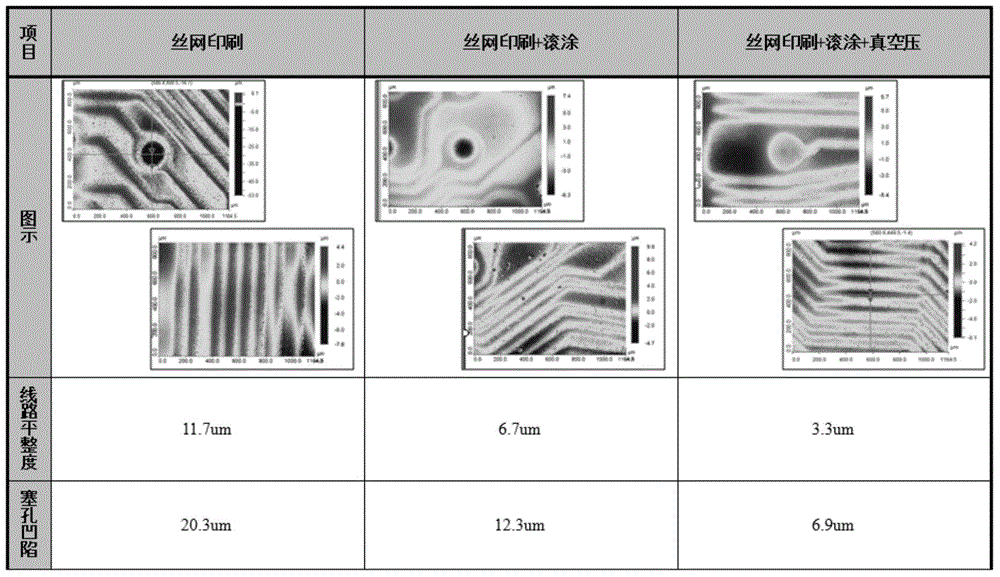

[0044] A method for manufacturing a solder resist on a printed circuit board, wherein the method comprises: a step of screen printing on the first surface, a first pre-baking step, a second screen printing step, a second pre-baking step, and a roll coating step, The third pre-baking step, exposure step, development step, post-curing step.

[0045] The following is based on figure 2 and image 3 As shown, among them, the screen printing first surface step and the first pre-baking step adopt the block screen and backing plate corresponding to the product graphics, and use the scraper to print the surface of the circuit board continuously, which is not only suitable for the needs The position of the plug hole is soldered to plug the hole, and at the same time a thin layer of solder resist is formed on the surface of the circuit board. Among them, in order to prevent the tool hole from being blocked, the upper stop point of the screen plate is increased by 100-200um compared wi...

Embodiment 2

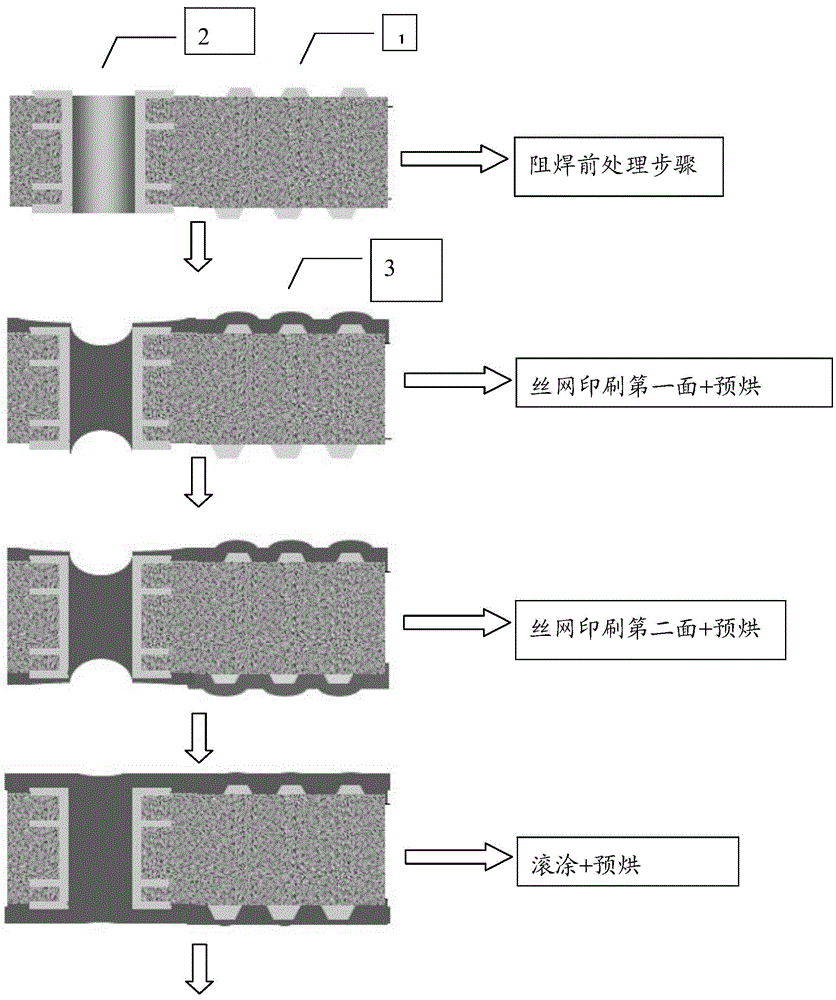

[0052] A method for manufacturing a printed circuit board solder resist, wherein the method includes: a pre-treatment step for solder resist, a step of screen printing on the first side, a first pre-baking step, a step of screen printing on the second side, and a second pre-baking step step, roll coating step, third pre-baking step, exposure step, development step, post-curing step.

[0053] Compared with Example 1, this embodiment adds a solder resist pretreatment step, that is, before printing the solder resist, the surface of the circuit board is treated with a specific physical or chemical method, the purpose of which is to clean the surface of the circuit board And roughening, the amount of micro-etching is controlled at 1±0.2um, so that the solder mask ink has a better bonding force with the surface of the circuit board, and prevents the solder mask from falling off.

Embodiment 3

[0055] A method for manufacturing a printed circuit board solder resist, wherein the method includes: a pre-treatment step for solder resist, a step of screen printing on the first side, a first pre-baking step, a step of screen printing on the second side, and a second pre-baking step step, roll coating step, third pre-baking step, vacuum treatment step, exposure step, development step, post-curing step.

[0056] Compared with Example 1, this embodiment can carry out vacuum pressure treatment on the pre-cured product before exposure, and through the vacuum, leveling and pressing of the vacuum laminator, the solder resist distribution on the surface of the circuit board is more uniform, and the thickness more consistent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com