A kind of preparation method of golden tofu

A tofu and gold technology, applied in dairy products, cheese substitutes, applications, etc., can solve the problems of difficult marketization and poor taste, and achieve the effects of high production efficiency, bright yellow color and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

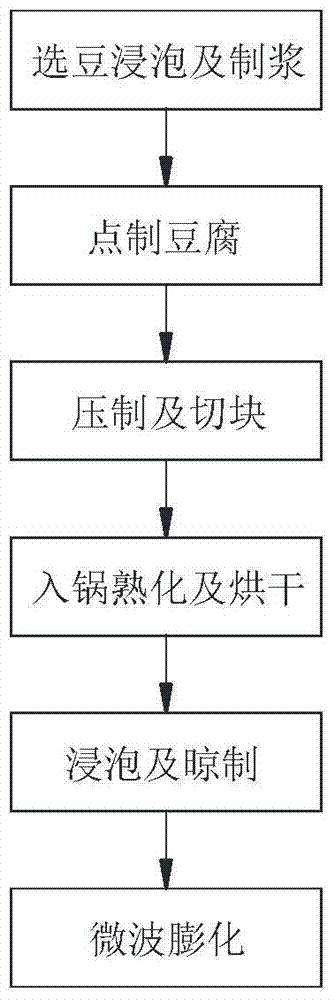

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of the golden bean curd of the present embodiment comprises the following steps:

[0023] S1. Selected soybean soaking and pulping: Select 50kg of high-quality soybeans, soak them in water at 20-50°C for 10-15 hours, add water to the soaked soybeans through a soybean milk machine to make 450L of soybean milk, and boil;

[0024] S2. Order tofu: Slowly add edible vinegar of 1% of the total volume of soy milk to the boiled soy milk in step S1 and keep stirring until the slurry is clear, and let it stand for 30 minutes;

[0025] S3. Pressing and cutting into pieces: drain the clarified liquid in step S2, press the tofu until no water overflows, and cut the pressed tofu into tofu pieces;

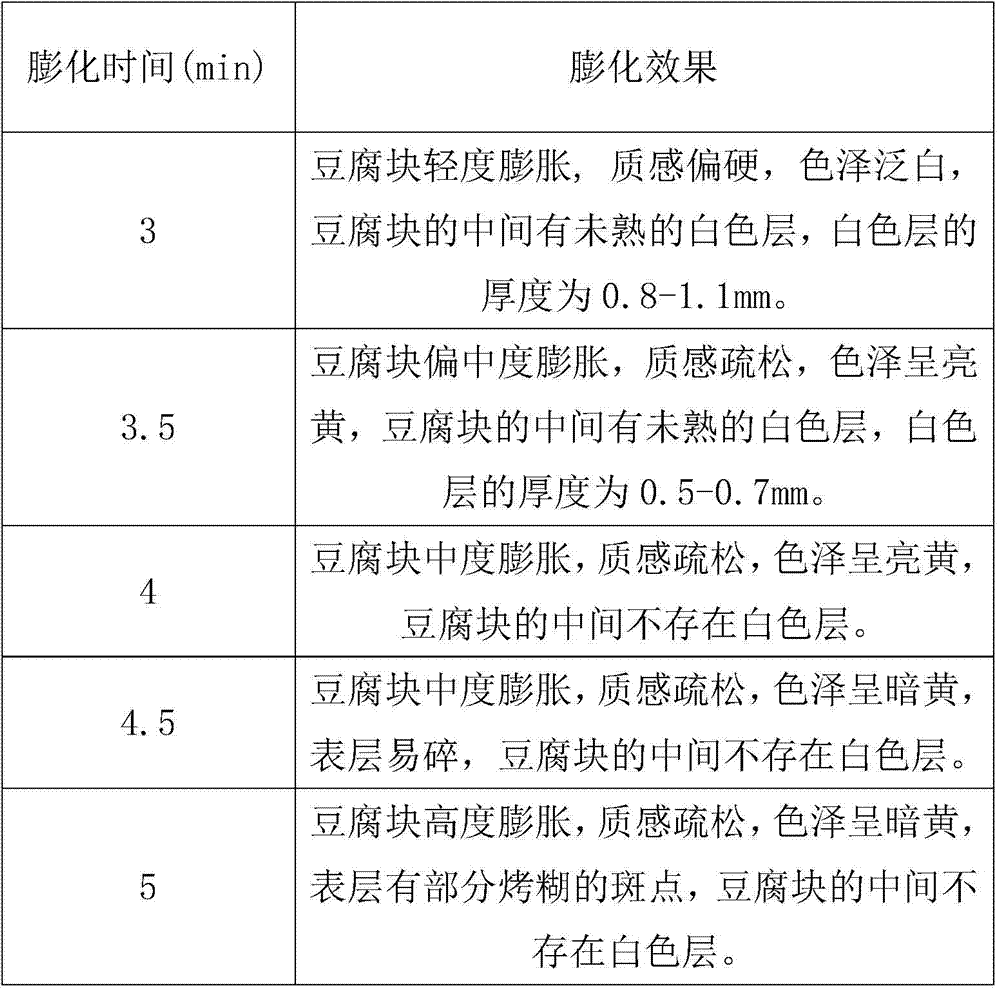

[0026] S4, aging and drying in a pot: put the tofu pieces in step S3 into alkaline water with a temperature of 90-100° C. and a concentration of edible alkali of 1.5% for 3-5 minutes, and place the cured tofu pieces at 30 Dry at ℃ for 48 hours, and turn over the tof...

Embodiment 2

[0030] The preparation method of the golden bean curd of the present embodiment comprises the following steps:

[0031] S1. Selected soybean soaking and pulping: Select 50kg of high-quality soybeans, soak them in water at 20-50°C for 10-15 hours, add water to the soaked soybeans through a soybean milk machine to make 450L of soybean milk, and boil;

[0032] S2. Order tofu: Slowly add 2.5% edible vinegar of the total volume of soy milk to the boiled soy milk in step S1 and keep stirring until the slurry is clear and let it stand for 30 minutes;

[0033] S3. Pressing and cutting into pieces: drain the clarified liquid in step S2, press the tofu until no water overflows, and cut the pressed tofu into tofu pieces;

[0034] S4, aging and drying in a pot: put the tofu pieces in step S3 into alkaline water with a temperature of 90-100° C. and a mass percentage concentration of edible alkali of 2.5% for 3-5 min, and place the cured tofu pieces at 40 Dry at ℃ for 48 hours, and turn ov...

Embodiment 3

[0038] The preparation method of the golden bean curd of the present embodiment comprises the following steps:

[0039] S1. Selected soybean soaking and pulping: Select 50kg of high-quality soybeans, soak them in water at 20-50°C for 10-15 hours, add water to the soaked soybeans through a soybean milk machine to make 450L of soybean milk, and boil;

[0040] S2. Order tofu: Slowly add edible vinegar of 3.5% of the total volume of soy milk to the boiled soy milk in step S1 and keep stirring until the slurry is clear, and let it stand for 30 minutes;

[0041] S3. Pressing and cutting into pieces: drain the clarified liquid in step S2, press the tofu until no water overflows, and cut the pressed tofu into tofu pieces;

[0042] S4, aging and drying in a pot: put the tofu pieces in step S3 into alkaline water with a temperature of 90-100° C. and a concentration of edible alkali of 3.5% for 3-5 minutes, and place the cured tofu pieces at 50 Dry at ℃ for 48 hours, and turn over the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com