Quetiapine fumarate sustained-release capsule and preparation method thereof

A technology for quetiapine fumarate and quinoline fumarate, which is applied in the field of pharmaceutical preparations and can solve the problems of complex process, many preparation steps and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

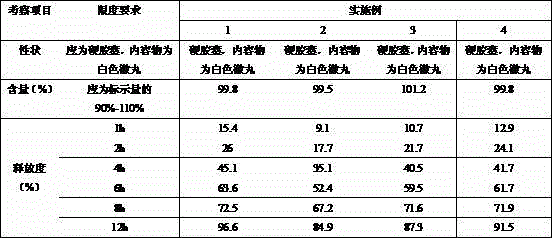

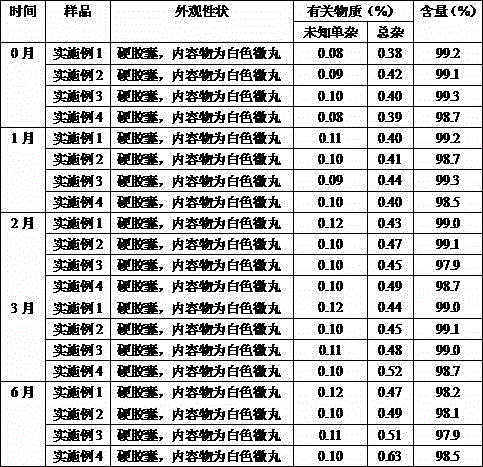

Examples

Embodiment 1

[0018] Example 1 Preparation of quetiapine fumarate sustained-release capsules (calculated as quetiapine, 50 mg)

[0019] Bead composition Dosage g Quetiapine Fumarate 58 Ethyl cellulose 20 Hypromellose 20 microcrystalline cellulose 110 Povidone K30 37 talcum powder 5 total 250

[0020] Preparation Process:

[0021] (1) Take the prescribed amount of quetiapine fumarate, ethyl cellulose, microcrystalline cellulose, povidone K30, and talcum powder, mix well, pass through an 80-mesh sieve and mix well;

[0022] (2) Prepare 3% hydroxypropyl methylcellulose aqueous solution as binder;

[0023] (3) Add appropriate amount of (2) to (1) to prepare soft material;

[0024] (4) Put the above-mentioned soft material into the extrusion spheronizer, extrude in a strip state, the extrusion mesh is 20 mesh, put the extruded strip in the centrifugal spheronizer, adjust the suitable speed of 200rpm-600rpm, and spheronize;

[0025] (5) ...

Embodiment 2

[0027] Example 2 Preparation of quetiapine fumarate sustained-release capsules (calculated as quetiapine, 200 mg)

[0028] Bead composition Dosage g Quetiapine Fumarate 230 Ethyl cellulose 50 Hypromellose 16.5 microcrystalline cellulose 53.5 Povidone K30 6 talcum powder 24 total 380

[0029] Preparation Process:

[0030] (1) Take the prescribed amount of quetiapine fumarate, ethyl cellulose, hydroxypropyl methyl cellulose, microcrystalline cellulose, and talcum powder, mix them evenly, and pass through an 80-mesh sieve to mix evenly;

[0031] (2) prepare 3% povidone K30 aqueous solution as adhesive;

[0032] (3) Add appropriate amount of (2) to (1) to prepare soft material;

[0033] (4) Put the above-mentioned soft material into the extrusion spheronizer, extrude in a strip state, the extrusion mesh is 20 mesh, put the extruded strip in the centrifugal spheronizer, adjust the suitable speed of 200rpm-600rpm, and sphero...

Embodiment 3

[0036] Example 3 Preparation of quetiapine fumarate sustained-release capsules (calculated as quetiapine, 300 mg)

[0037] Bead composition Dosage g Quetiapine Fumarate 345 Ethyl cellulose 86.25 Hypromellose 86.25 microcrystalline cellulose 103.5 Povidone K30 2.1 silica 6.9 total 630

[0038] (1) Take the prescribed amount of quetiapine fumarate, ethyl cellulose, microcrystalline cellulose, povidone K30, and talcum powder, mix well, pass through an 80-mesh sieve and mix well;

[0039] (2) Prepare 3% hydroxypropyl methylcellulose aqueous solution as binder;

[0040] (3) Add appropriate amount of (2) to (1) to prepare soft material;

[0041] (4) Put the above-mentioned soft material into the extrusion spheronizer, extrude in a strip state, the extrusion mesh is 20 mesh, put the extruded strip in the centrifugal spheronizer, adjust the suitable speed of 200rpm-600rpm, and spheronize;

[0042] (5) Dry in a fluidized bed un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com