Crystallizing device for preparing high-purity rebaudioside A by employing continuous purification, and control method of crystallizing device

A crystallization device and high-purity technology, applied in chemical instruments and methods, solution crystallization, preparation of sugar derivatives, etc., can solve the problem of high energy consumption, production cost and waste discharge, inability to realize batch continuous production, and discrete unit operation process. and other problems, to achieve the effect of automatic continuous production, stable and reliable production system, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

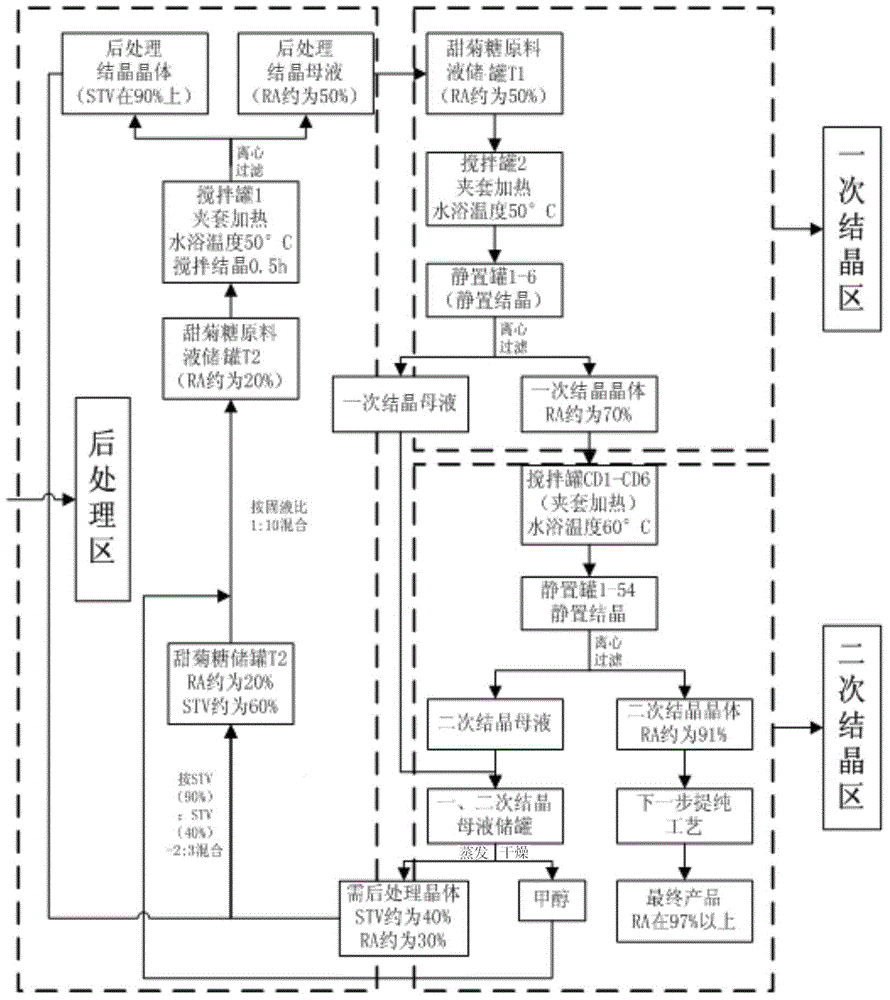

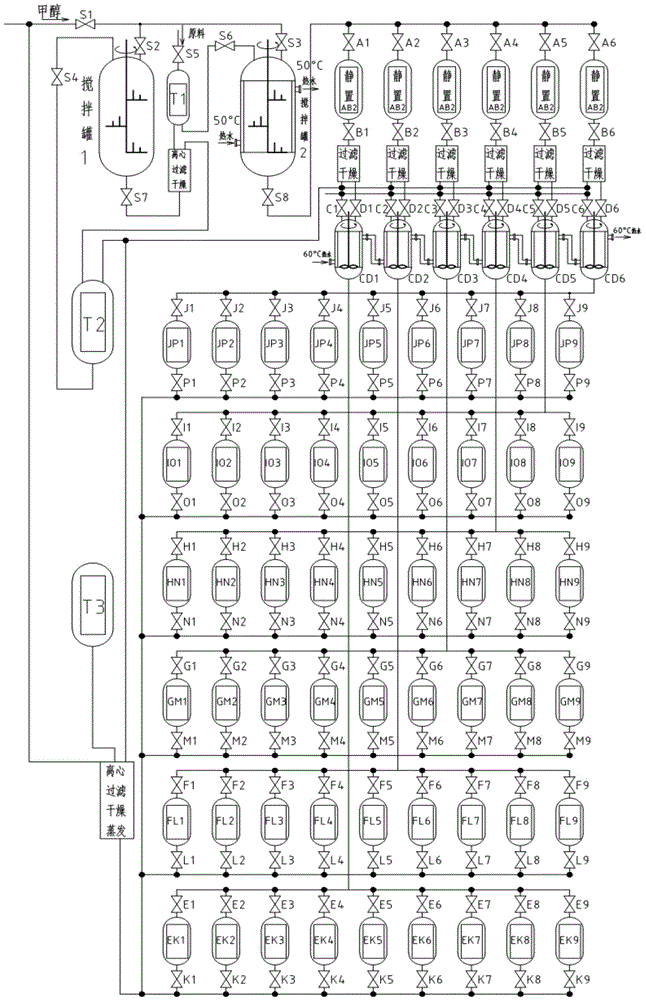

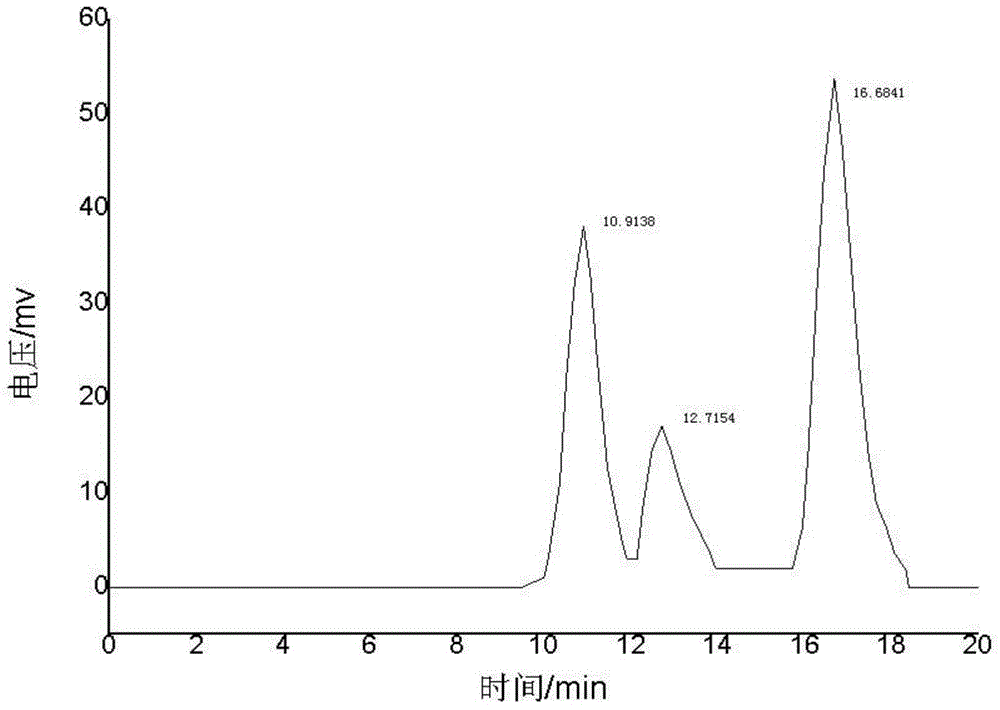

[0041] Described stevioside raw material (RA content is about 50%, its HPLC detection result is as attached image 3 Shown) mixed with methanol solution at a solid-to-liquid ratio of 1:8, sent to the stirring tank 2, stirred and dissolved, and hot water at 50°C was passed through the jacket from bottom to top, after stirring for 5 minutes, press the valve in Table 1 above The control flow is sent into static tanks AB1-AB6 in turn, and crystallized in static tanks AB1-AB6 for 0.5h, solid-liquid separation, and the HPLC detection result of the primary crystallization crystal is as follows: Figure 4 Shown; Mix the primary crystallized product with methanol aqueous solution at a solid-to-liquid ratio of 1:8, and send them into the stirring tank CD1-CD6 in chronological order, and pass hot water at 60°C from bottom to top in the jacket, and stir for 10 minutes. , Feed liquid is sent in corresponding static tank, static crystallization 9h, solid-liquid separation, get high-purity R...

Embodiment 2

[0045] The stevioside raw material (RA content is about 50%) is mixed with methanol solution at a solid-to-liquid ratio of 1:5, sent into the stirring tank 2, stirred and dissolved, and hot water at 35°C is passed through the jacket from bottom to top, and stirred for 15 minutes Afterwards, according to the valve control flow process in above Table 1, send into static tank AB1-AB6 successively, in static tank AB1-AB6, static crystallization 1h, solid-liquid separation; The liquid ratio is 1:10 and mixed, and sent to the stirring tank CD1-CD6 in sequence in time, and the hot water of 40°C is passed through the jacket from bottom to top, and after stirring for 15 minutes, the material liquid is sent to the corresponding static tank. Static crystallization for 10 hours, solid-liquid separation, to obtain high-purity RA crystals; primary crystallization and secondary crystallization mother liquor are evaporated and dried, methanol is recovered, sent to methanol storage tank for rec...

Embodiment 3

[0049]The stevioside raw material (RA content is about 50%) is mixed with methanol solution at a solid-to-liquid ratio of 1:10, sent into the stirring tank 2, stirred and dissolved, and 60°C hot water is passed through the jacket from bottom to top, and stirred for 20 minutes Finally, according to the valve control flow process in above table 1, send into static tank AB1-AB6 successively, in static tank AB1-AB6, static crystallization 40min, solid-liquid separation; Mix liquid at a ratio of 1:5, and send them into the stirring tanks CD1-CD6 in chronological order, pass hot water at 70°C from bottom to top in the jacket, and after stirring for 30 minutes, send the material liquid into the corresponding static tank. Static crystallization for 5 hours, solid-liquid separation, and high-purity RA crystals were obtained; primary crystallization and secondary crystallization mother liquor were evaporated and dried, methanol was recovered, and sent to a methanol storage tank for recyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com