Preparation method of soil heavy-metal stabilizer

A heavy metal stabilizer and soil technology, which is applied in the restoration of polluted soil, chemical instruments and methods, and other chemical processes, can solve the problems of difficult adsorption of heavy metals, strong hydrophobicity, etc., achieve carbon sequestration, short repair time, Eases the effect of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

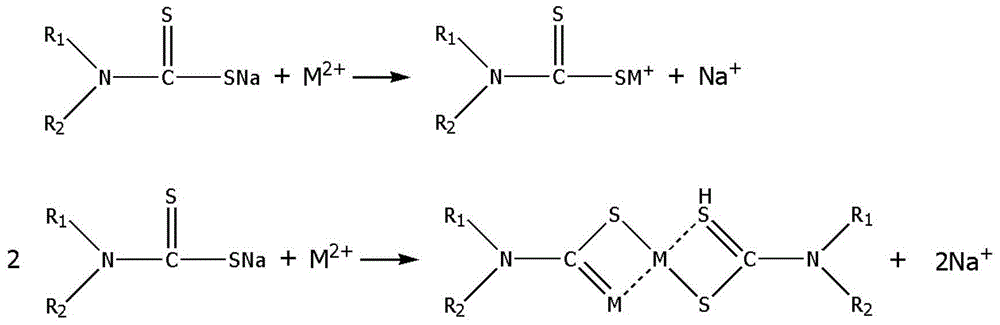

Method used

Image

Examples

Embodiment 1

[0031] a. Preparation of activated biochar:

[0032] Take corncobs and place them in an oven to dry at 60°C, crush them to 200 mesh, impregnate them with 0.5mol / L NaOH solution for 18 hours, and then 3 N / min 2 Under protection, burn at 500°C for 4 hours, cool to room temperature, wash with distilled water, and dry to obtain activated biochar;

[0033] b. Preparation of activated organic composite biochar:

[0034] The sodium dithiocarbamate derivative solution with a concentration of 10mmol / L was mixed with activated biochar at a weight ratio of 1:100, and balanced and oscillated at a speed of 60r / min for 6 days under dark conditions, and then Centrifuge at 2000r / min for 15min, remove the supernatant, collect the precipitated mixture, and dry to obtain a soil metal stabilizer.

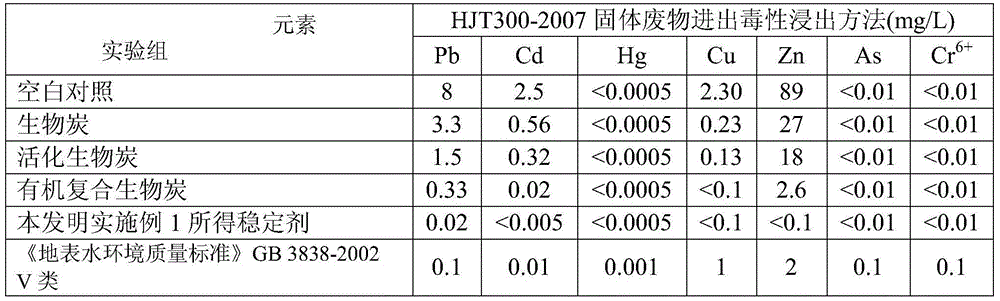

[0035] In order to verify the technical effect of the present invention, polluted soil around a smelter was taken as a sample, crushed and screened. The following tests were specially made, and the...

Embodiment 2

[0041] a. Preparation of activated biochar:

[0042] Take the straw and place it in an oven to dry at 50°C, crush it to 200 mesh, impregnate it with a 0.1mol / L KOH solution for 24 hours, and 3 N / min 2 Under protection, burn at 200°C for 4 hours, cool to room temperature, wash with distilled water, and dry to obtain activated biochar;

[0043] b. Preparation of activated organic composite biochar:

[0044] The sodium pyrrolidine dithiocarbamate solution with a concentration of 1mmol / L was mixed with activated biochar at a weight ratio of 1:120, and balanced and oscillated at a speed of 60r / min for 5 days under dark conditions, and then Centrifuge at 2000r / min for 15min, remove the supernatant, collect the precipitated mixture, and dry to obtain a soil metal stabilizer.

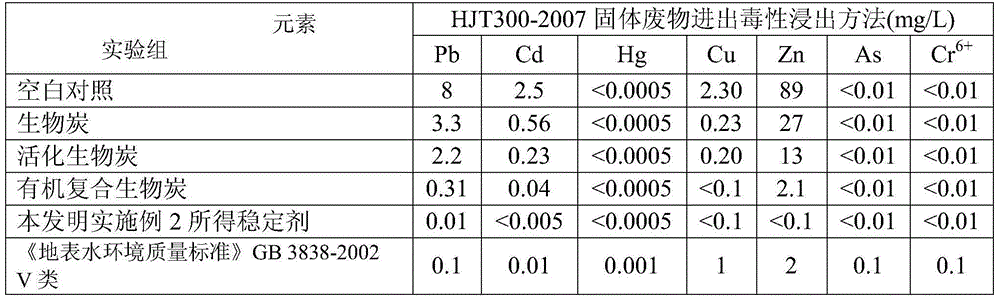

[0045] In order to verify the technical effect of the present invention, polluted soil around a smelter was taken as a sample, crushed and screened. The following tests were specially made, and the test res...

Embodiment 3

[0051] a. Preparation of activated biochar:

[0052] Take rice husk and banana stem and mix them evenly at a weight ratio of 2:1, place them in an oven and dry them at 40°C, crush them to 200 mesh, and use a concentration of 1mol / L Mg(OH) 2 The solution was soaked for 3 hours, and then the air velocity was 150cm 3 N / min 2 Under protection, burn at 700°C for 4 hours, cool to room temperature, wash with distilled water, and dry to obtain activated biochar;

[0053] b. Preparation of activated organic composite biochar:

[0054] Mix the sodium bibenzyl dithiocarbamate solution with a concentration of 20mmol / L and the activated biochar at a weight ratio of 1:80, balance and shake at a speed of 60r / min for 7 days under dark conditions, and then Centrifuge at 2000r / min for 15min, remove the supernatant, collect the precipitated mixture, and dry to obtain a soil metal stabilizer.

[0055] In order to verify the technical effect of the present invention, polluted soil around a sme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com