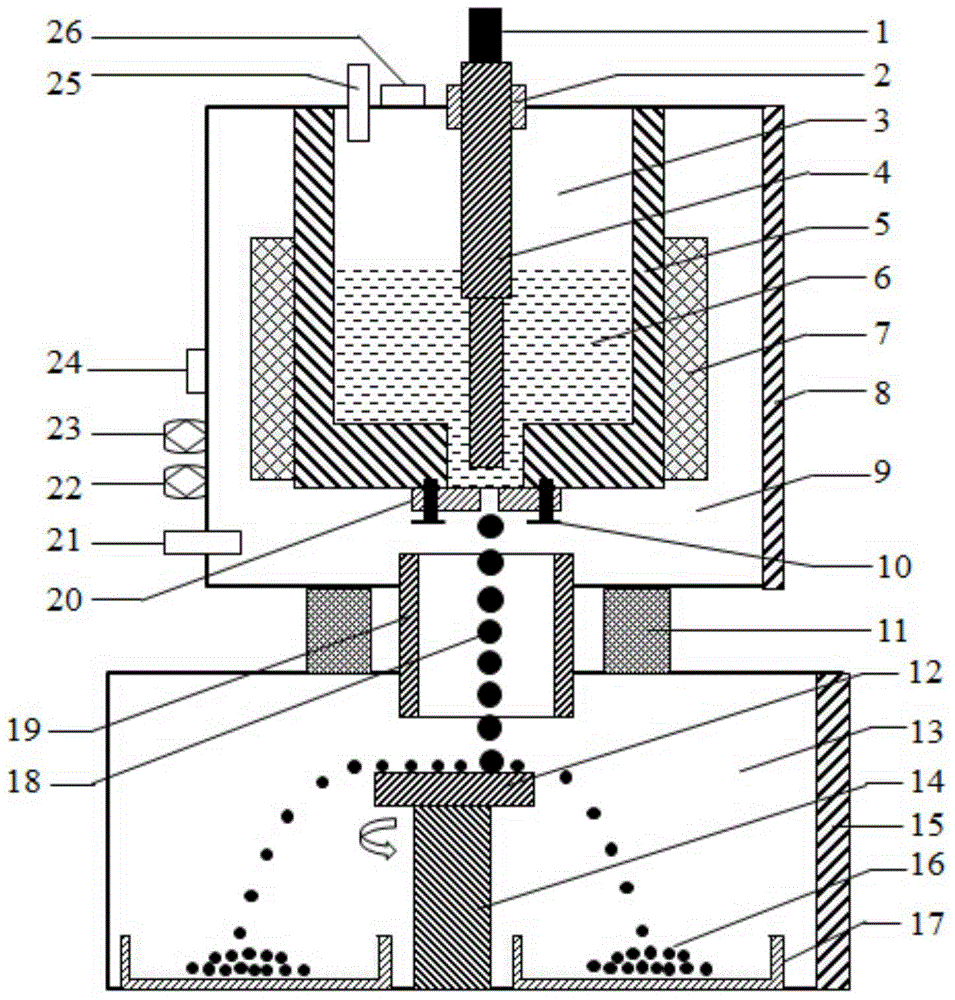

Method and device for preparing superfine spherical high-melt-point metal powder for 3D printing

A high melting point metal, 3D printing technology, applied in the field of high melting point metal powder preparation, can solve the problems of poor sphericity, poor spreadability and fluidity, and achieve the effect of reducing size, controllable particle size and improving output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Prepare copper metal powder for 3D printing with the above-mentioned device and method, and the specific implementation method is as follows:

[0046] First, the copper block is broken into block particles with a particle diameter of 2 cm, and the crucible 5 with a central hole in the bottom is packed into it. The amount of copper particles loaded reaches 1 / 2 of the capacity of the crucible 5, and then the material is made of graphite. Bolts with small holes (i.e. pads 20 with small holes) are installed to the bottom of the crucible 5 through four evenly distributed screws 10, and the furnace door 8 is closed; the crucible chamber 3, the housing 9 and the collection The chamber 13 is pumped to a low vacuum of 1Pa-5Pa, and then the diffusion pump 22 is used to pump a high vacuum to 10 -3 Pa, filled with high-purity inert gas argon to atmospheric pressure; set the power to energize the heating belt 7, and continue to heat up to overheating 10°C after the temperature reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com