Large-scale preparation method of silver nano-sheets

A silver nanosheet, a large number of technologies, applied in the field of nanomaterials, can solve the problems of difficult dispersion of product agglomeration, small product concentration, complex reaction system, etc., and achieve the effect of no exhaust gas emission, simple equipment, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing silver nanosheets in large quantities, the steps are as follows:

[0032] (1) At a temperature of 30°C, disperse the silver nanosheet seed crystals in water to obtain a suspension with a solid content of 0.03g / L, then add 2mL of the suspension to 415mL of a 0.28mmol / L sodium citrate aqueous solution In the solution, stir and mix evenly, add 21 μL of hydrazine hydrate, and then slowly add 3 mL of silver nitrate aqueous solution with a concentration of 59 mmol / L. The injection time of the silver nitrate aqueous solution is 1 min, and the reaction is stirred at a constant temperature for 1 h to generate a product suspension;

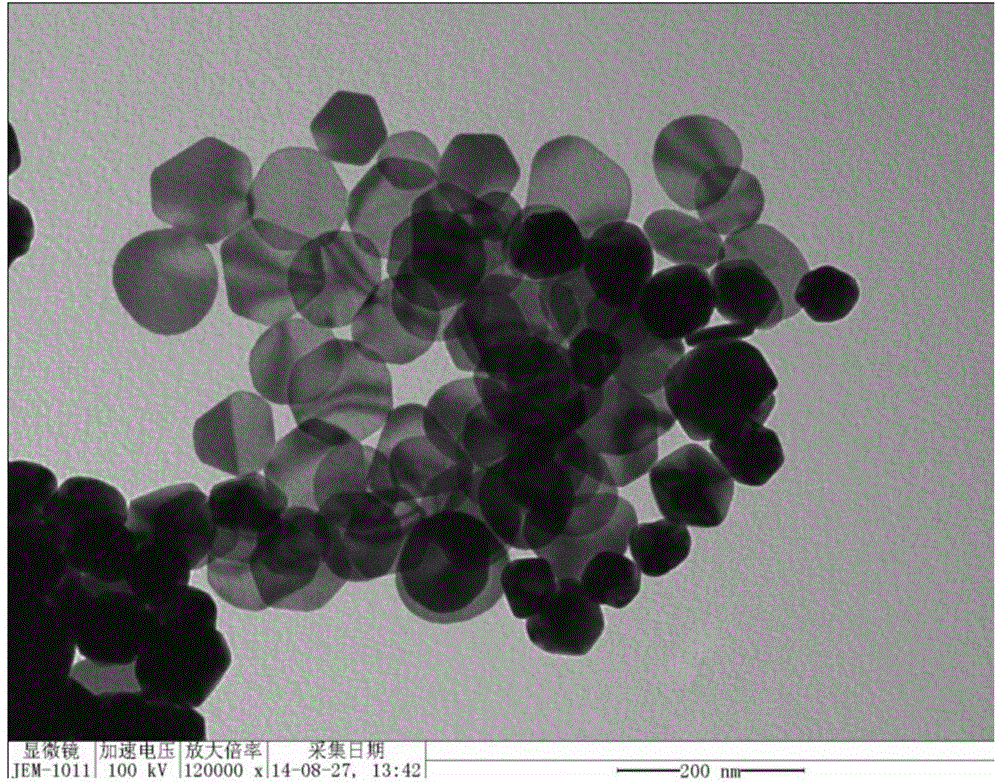

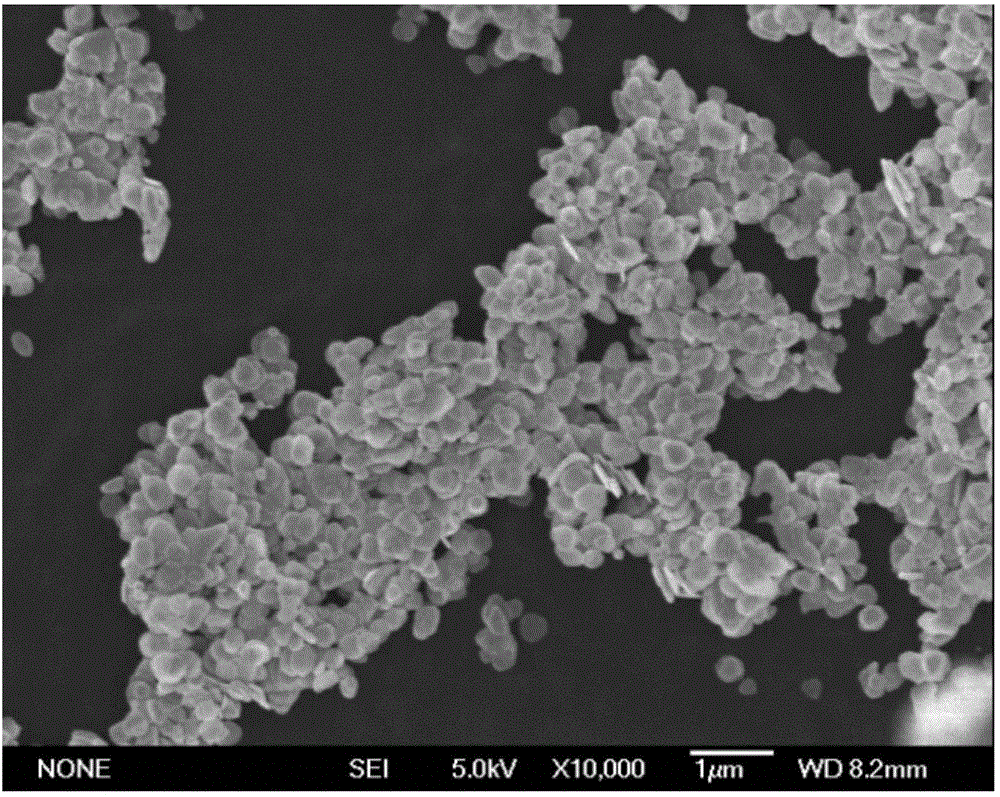

[0033] (2) Centrifuge and wash the product suspension generated in step (1) to obtain the product. The yield is 99%, the purity is 95%, the side length of the silver nanosheet is about 95nm±8nm, and the thickness is 20±1.2nm.

Embodiment 2

[0035] A method for preparing silver nanosheets in large quantities, the steps are as follows:

[0036] (1) At a temperature of 30°C, disperse the silver nanosheet seed crystals in water to obtain a suspension with a solid content of 0.03g / L, then add 2mL of the suspension to 415mL of a 1.3mmol / L sodium citrate aqueous solution In the solution, stir and mix evenly, add 110 μL of hydrazine hydrate, and then slowly add 15 mL of silver nitrate aqueous solution with a concentration of 59 mmol / L. The injection time of the silver nitrate aqueous solution is 10 minutes, and the reaction is stirred at a constant temperature for 1 hour to generate a product suspension;

[0037] (2) Centrifuge and wash the product suspension generated in step (1) to obtain the product. The yield is 99%, the purity is 93%, the side length of the silver nanosheet is about 111±15nm, and the thickness is 19±2.2nm.

Embodiment 3

[0039] A method for preparing silver nanosheets in large quantities, the steps are as follows:

[0040](1) At a temperature of 30°C, disperse the silver nanosheet seed crystals in water to obtain a suspension with a solid content of 0.03g / L, then add 10mL of the suspension to 75mL of a sodium citrate aqueous solution with a concentration of 8.2mmol / L In the solution, stir and mix evenly, add 110 μL of hydrazine hydrate, and then slowly add 15 mL of silver nitrate aqueous solution with a concentration of 59 mmol / L. The injection time of the silver nitrate aqueous solution is 10 minutes, and the reaction is stirred at a constant temperature for 1 hour to generate a product suspension;

[0041] (2) Centrifuge and wash the product suspension generated in step (1) to obtain the product. The yield is 95%, the purity is 98%, the side length of the silver nanosheet is about 102±7nm, and the thickness is 19±2.2nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com