A grinding explosion-proof vacuum cleaner for vacuum melting furnace

A technology of vacuum melting furnace and vacuum cleaner, which is applied in grinding machines, portable grinding machines, grinding/polishing equipment, etc., can solve the problem of inability to handle easily oxidized dust, and achieve the effect of eliminating hidden dangers in production, improving work efficiency and avoiding dust explosions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

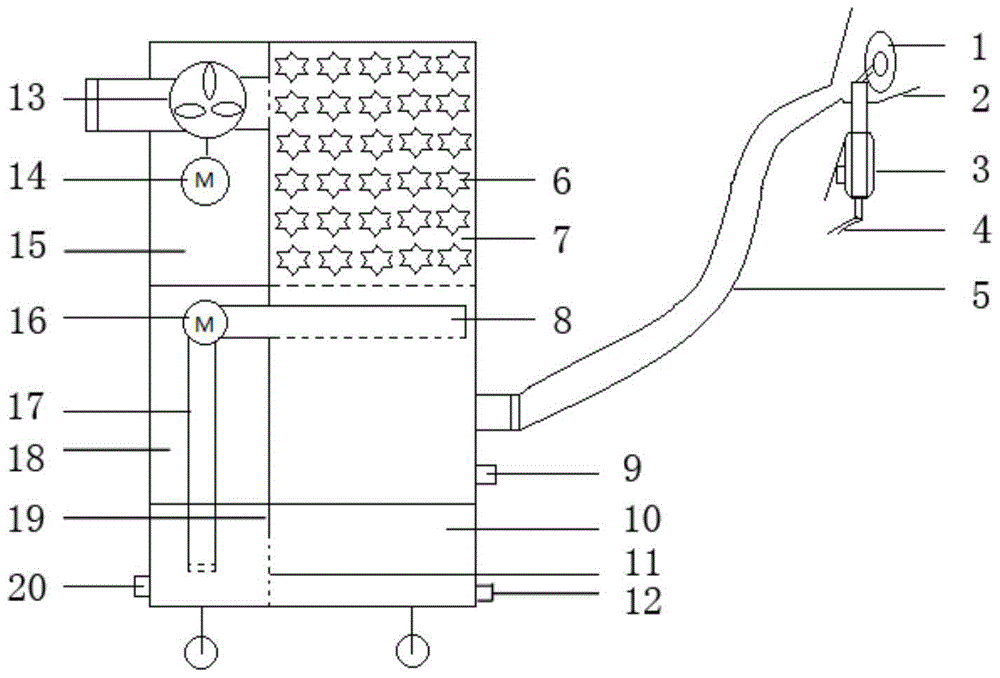

[0019] like figure 1 , the explosion-proof dust collection body is divided into four chambers by stainless steel plates: spray chamber 10, pumping chamber 18, filter chamber 7, and exhaust chamber 15, in which a filter screen 11 is installed on the lower part of the spray chamber 10 and the pumping chamber 18, and the spray chamber 10 and the filter chamber 7 are divided by a perforated steel plate so that the air flow can pass through. The specific components of the grinding explosion-proof vacuum cleaner include a hand-held grinding machine 3, a wire brush 1, a dust collection port 2, a spray chamber 10, a spray pipe 8, a pumping motor 16, an upper water pipe 17, a filter screen 11, a filter ball 6, and a fan 13 , the exhaust motor 14, its connection mode and position are that the wire brush 1 is fixed on the rotating shaft of the hand-held grinder 3 with screws, the dust collection port 2 is fixed on the front end of the grinder 3, and is connected with the body of the vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com