High-precision numerical control liquid shot blasting machine

A liquid shot peening and high-precision technology, which is applied in the direction of abrasive jet machine tools, used abrasive processing devices, abrasives, etc., can solve the problem that the spray gun mechanism cannot meet the high-precision positioning requirements, and achieve the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

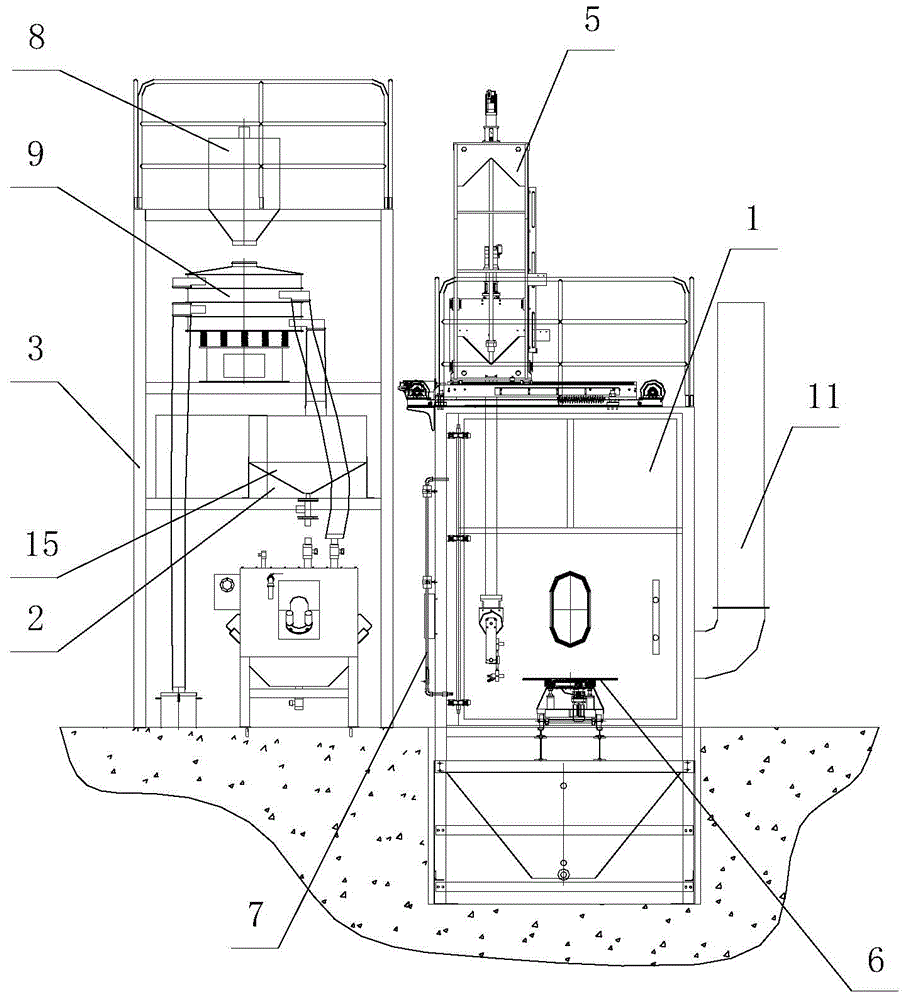

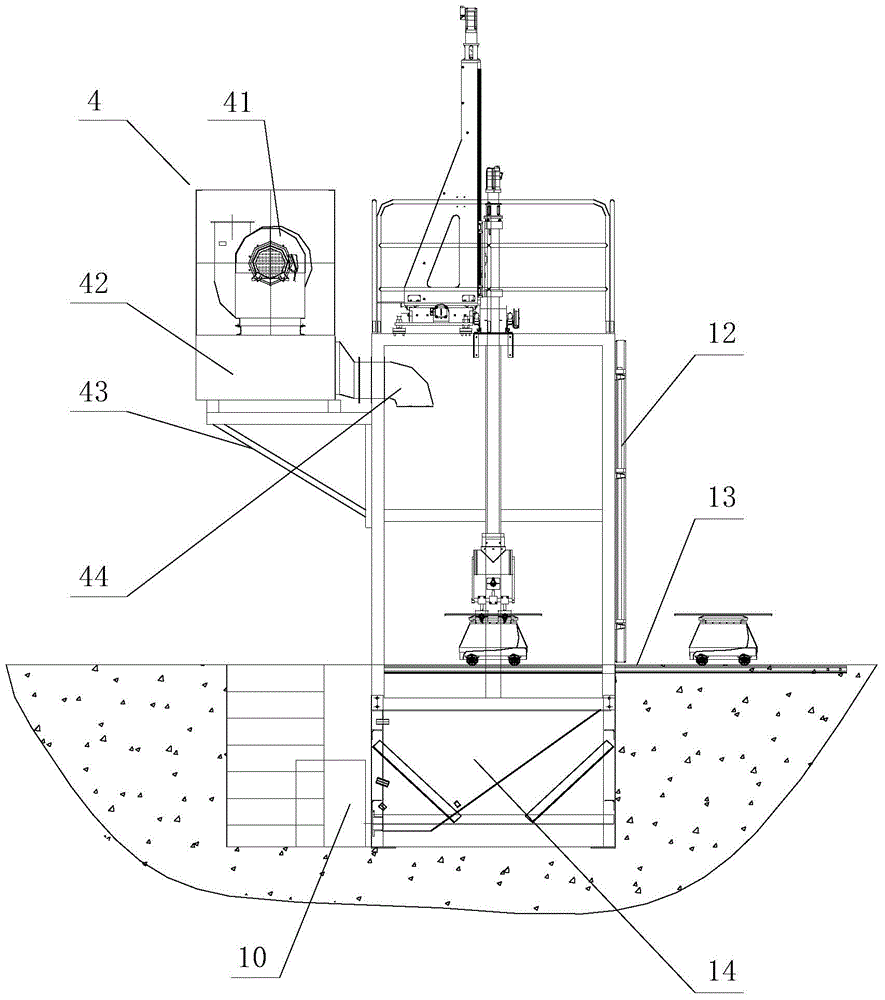

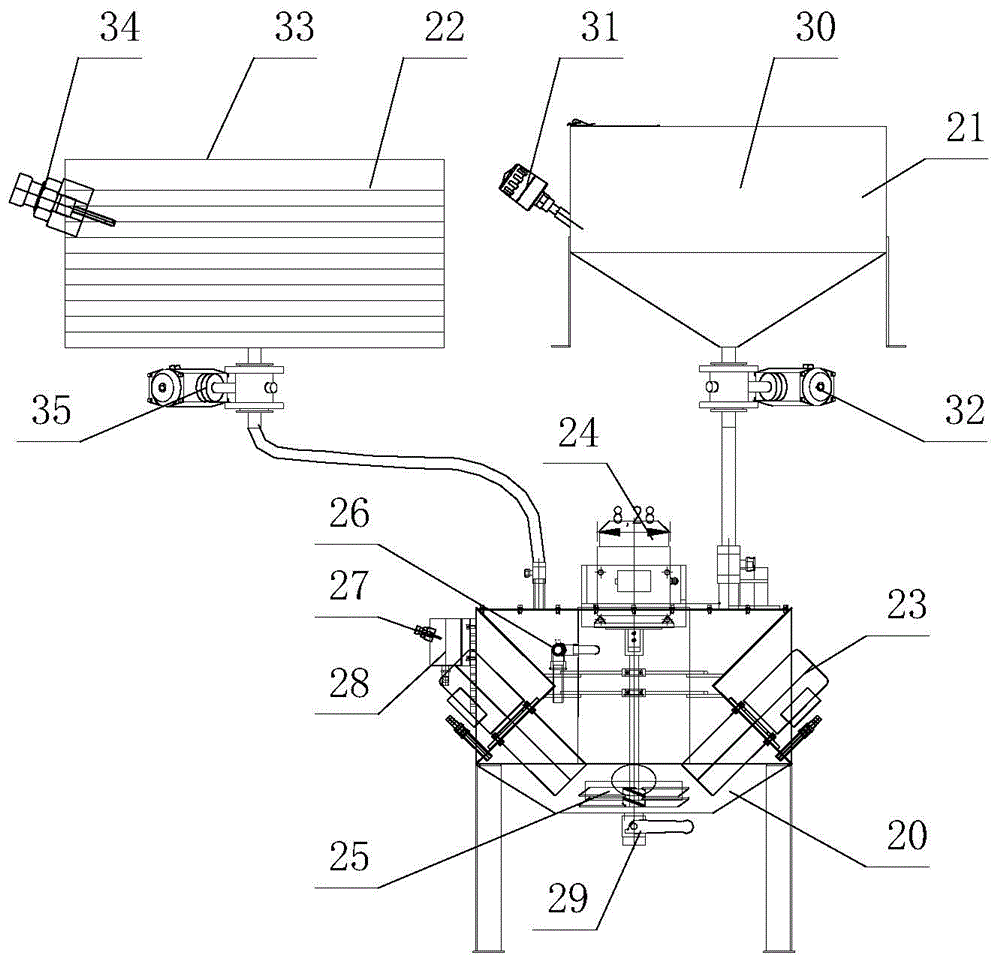

[0030] The present invention provides a high-precision numerical control liquid shot blasting machine. In order to make those skilled in the art understand the solution of the present invention more clearly, and to make the above-mentioned purpose, characteristics and beneficial effects of the present invention more clear and easy to understand, the following combined with Figure 1~6 The present invention will be further described in detail with specific embodiments.

[0031] A high-precision numerically controlled liquid shot blasting machine, comprising a manipulator spray gun mechanism 5 and a workpiece conveying turntable 6. The manipulator spray gun mechanism 5 includes a spray gun mechanism 54, a Z-axis mechanical arm 51, an X-axis mechanical arm 52, a B-axis mechanical arm 53, and a B-axis mechanical arm 53. The mechanical arm 53 includes a B-axis sliding seat 58 and a steering gear 60. The mechanical Z-axis mechanical arm 51 and the X-axis mechanical arm 52 are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com