A Method for Producing Reinforced Concrete Pipes by Extruding and Demolding with Dual Vibration Sources

A reinforced concrete pipe, double vibration technology, applied in the direction of mold, reinforced molding, ceramic molding machine, etc., can solve the problems of reducing the service life of equipment, using more manpower, damage and wear, etc. Environmental protection, the effect of using less power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

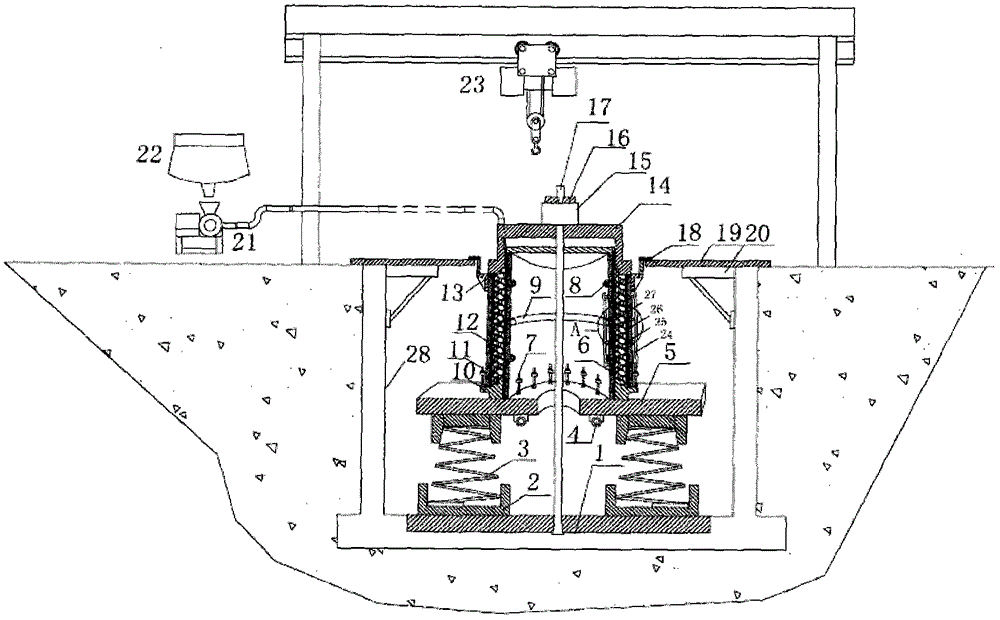

[0082] The invention provides a vibrating table structure for producing a reinforced concrete pipe system by extruding and demoulding with dual vibration sources, the vibrating table includes a vibrating table base plate 1, a spring limit seat 2, a supporting spring 3, a vibrating table high-frequency The vibrator 4 and the vibrating table bottom plate 5, the upper end of the supporting spring 3 is fixed to the vibrating table bottom plate 5 through the spring limiting seat 2, the lower end of the supporting spring 3 is fixed to the vibrating table base plate 1 through the spring limiting seat 2, and the high frequency of the vibrating table The vibrator 4 is fixed below the vibrating table bottom plate 5; the vibrating table base plate 1 is fixed at the bottom of the foundation pit 28; the supporting spring 3 is a conical spring with a small upper part and a larger lower part; A support spring 3 constitutes an elastic support structure, the elastic support structure is at leas...

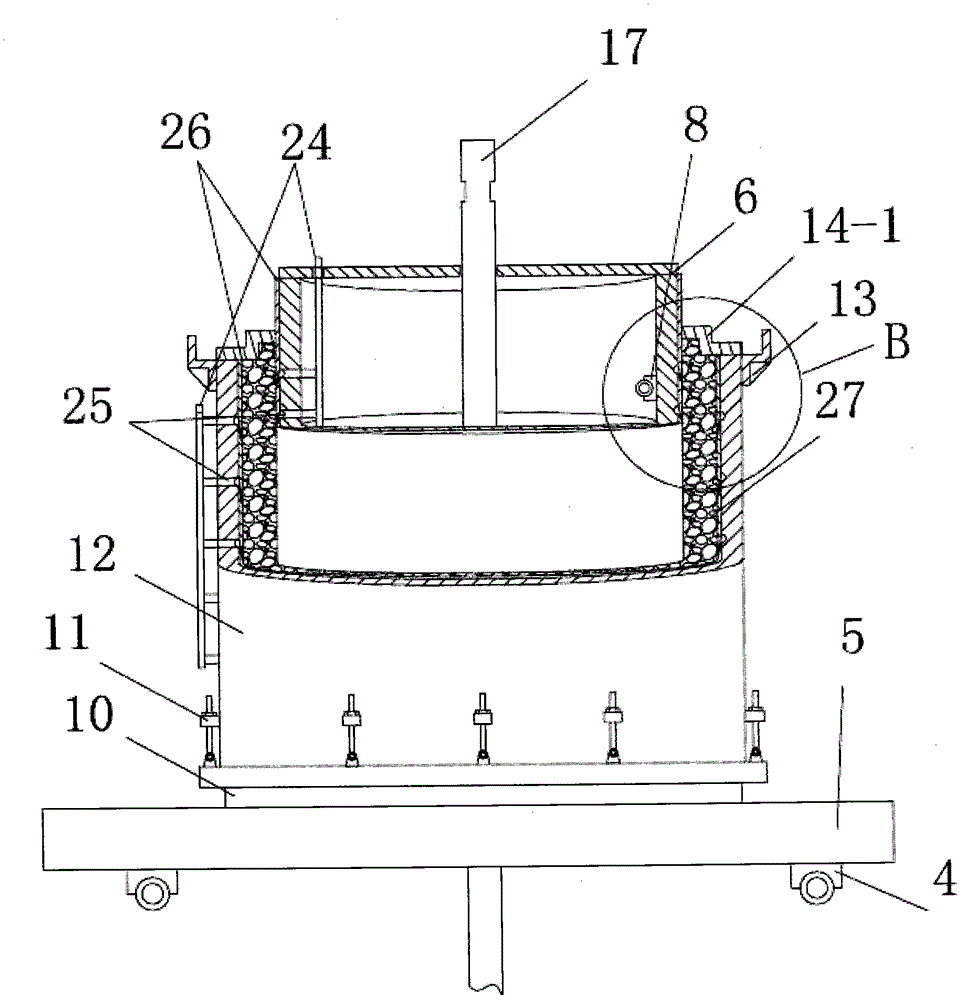

Embodiment 2

[0084] The invention provides an inner circular mold vibrating cylinder for producing a reinforced concrete pipe system by extruding and demolding with double vibration sources, the inner circular mold vibrating cylinder comprises an inner circular mold cylinder 6, an inner circular mold connecting bolt 7, an inner circular mold The support ring 9 and the high-frequency vibrator 8 of the inner circle mold, the inner circle mold barrel 6 is installed on the vibrating table of the pipe system through the inner circle mold connecting bolt 7, and the inner circle mold support ring 9 is installed on the inner circle mold barrel 6 Among them, the inner circular mold high frequency vibrator 8 is installed on the inner wall of the inner circular mold cylinder 6; There are a plurality of stripping rings, which are plugged to form a stripping outer wall that matches the shape of the outer wall of the inner mold cylinder 6, and the upper end of the next stripping ring presses the lower en...

Embodiment 3

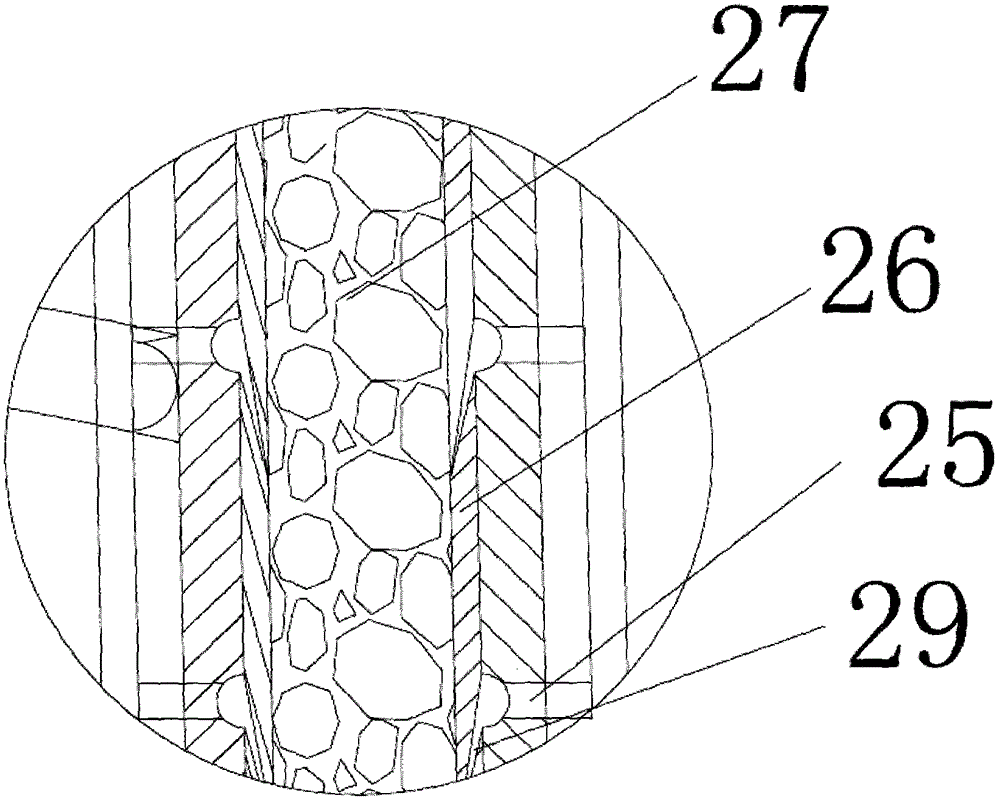

[0086] The invention provides an outer circular mold barrel structure for producing reinforced concrete pipe system through extrusion and demoulding with double vibration sources. 12 and mold retaining ring 13, the inner circle mold barrel 6 is located in the outer circle mold barrel 12 and the annular cavity for producing reinforced concrete pipe 27 is formed between the inner and outer circle mold barrels 12, and the outer circle mold bottom ring 10 passes through the outer circle mold The connecting bolt 11 is used to be installed on the bottom end of the outer cylindrical mold barrel 12 and close the bottom of the annular cavity, and the mold stop ring 13 is sleeved on the outer wall of the outer cylindrical mold barrel 12 and protrudes from the outer cylindrical mold barrel 12 The top of the outer circular mold cylinder 12 is shaped as a truncated cone with a small upper part and a larger lower one; a plurality of demoulding rings are set on the inner wall of the outer cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com