Irradiation type lathe guide rail heating cover and use method thereof

A technology of heating mantle and guide rail, applied in the field of guide rail heating mantle, can solve the problems of long curing time, affecting the production cycle of machine tool assembly, etc., and achieve the effects of improving production environment, shortening drying time, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

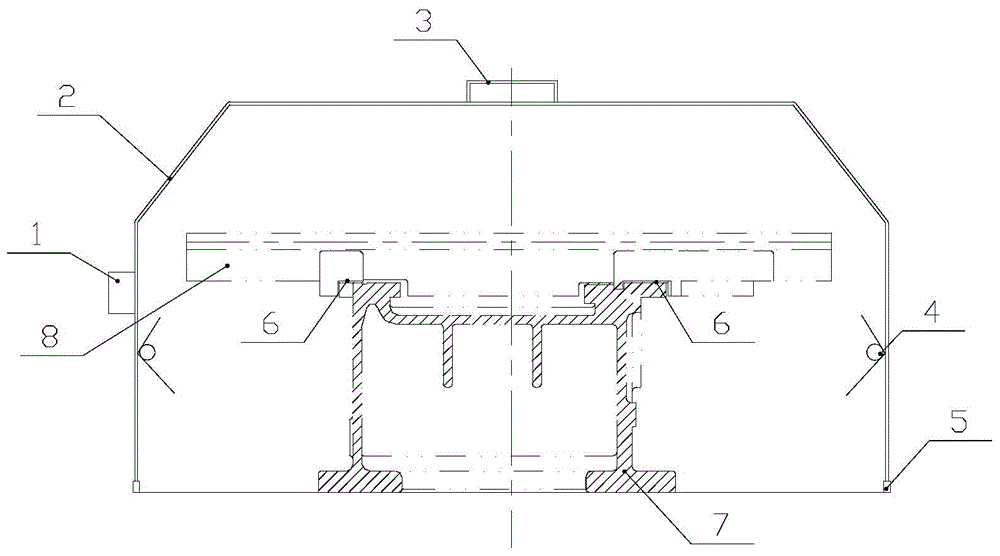

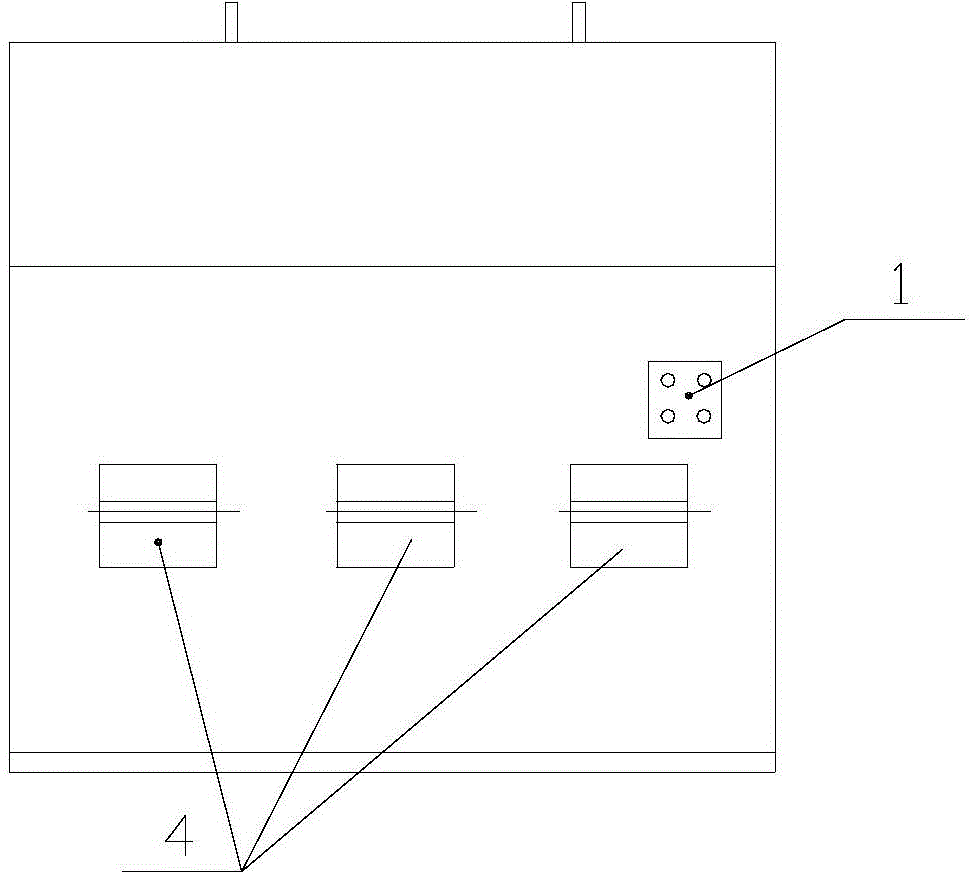

[0031] Example 1: see figure 1 , an irradiation type machine tool guide rail heating cover, the heating cover 2 covering the machine tool guide rail 7 in the axial direction wraps the machine tool guide rail 7, a plurality of infrared heating lamp tubes 4 are arranged in the heating cover 2, and the infrared heating lamp tube 4 is under the A rubber pad 5 is provided, and a soft belt 6 is provided at the junction between the machine tool guide rail 7 and the bed saddle 8; the heating cover 2 is also provided with a control device 1 .

[0032] As for the irradiated machine tool guide rail heating cover, the heating cover 2 is rectangular, its rear end surface wraps the machine tool guide rail, its front end is sealed with the machine tool guide rail, and its left and right sides touch the ground. A handle 3 is provided on the heating cover 2 .

Embodiment 2

[0033] Embodiment 2: The heating cover for the guide rail of the irradiated machine tool, the heating cover 2 is a plurality of cover bodies, and the cover bodies are connected by connecting buckles. All the other structures are the same as in Example 1.

Embodiment 3

[0034] Embodiment 3: A method for bonding soft belts of machine tool guide rails using an irradiated machine tool guide rail heating cover, the main feature of which is that the steps are:

[0035] (1) To remove rust and oil on the bonding surface of the metal guide rail, first use emery cloth, sandpaper or wire brush to remove rust spots and impurities, then scrub with acetone and dry; if the old machine tool is seriously oily, first use NaOH lye to scrub, and then Then scrub with acetone; or sandblast the bonding surface of the metal guide rail; at the same time, scrub the dark brown bonding surface of the soft belt with acetone and dry it for later use, but do not use sandpaper or other items to polish the bonding surface of the soft belt to prevent damage surface treatment layer;

[0036] (2) When splicing or butting the soft tape, the seam must be tight and the edges should be smooth;

[0037] (3) Glue dispensing: Adhesives for machine tool guide rails must be used as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com